Tubular Experimental Electric Furnace

Tubular Experimental Electric Furnace

We can provide customized models based on customers’requirements. The common models are listed below. The production cycle is 40days.

Technical Specification of TC-10G Series 1,000℃ TubularExperimental Electric Furnace

| Model | Service Temperature (℃) | Diameter of Tube (mm) | Length of Constant Temperature Section (mm) | Power (kW) | Voltage (V) |

| TC—14G1 | 1,000 | 40 | 80—400 | 2—5 | 220 |

| TC—14G2 | 1,000 | 50 | 80—400 | 5—8 | 220 |

| TC—14G3 | 1,000 | 60 | 80—400 | 8—10 | 380 |

| TC—14G4 | 1,000 | 80 | 80—400 | 10—12 | 380 |

Technical Specification of TC-14G Series 1,400℃ Tubular Experimental Electric Furnace

| Model | Service Temperature (℃) | Diameter of Tube (mm) | Length of Constant Temperature Section (mm) | Power (kW) | Voltage (V) |

| TC—14G1 | 1,400 | 40 | 80—400 | 2—5 | 220 |

| TC—14G2 | 1,400 | 80 | 80—400 | 5—8 | 380 |

| TC—14G3 | 1,400 | 100 | 80—400 | 8—10 | 380 |

| TC—14G4 | 1,400 | 120 | 80—400 | 10—12 | 380 |

Based on the box experimental electric furnace, the tubular experimentalchanges the shape to meet special experimental needs. It can be widely used intemperature controlling in college experiments and product developments. Thecontrol panel provides easy configuration for the users to realize automaticheating, preservation, and cooling process. The accuracy of temperaturecontrolling can be ±1℃.

We strictly choose corundum 99 ceramic as the furnace tube material. Thismaterial has good heatproof and heat insulation property, and it is verydurable which makes it a good choice under high-temperature circumstance inlong-term use. It can create a uniform heating environment inside the furnace.Tests show the temperature difference is under ±1℃, so it can ensure theexperimental results reasonable and reliable. The temperature of the surface offurnace can be kept around room temperature. Protective gas such as oxygen,nitrogen, argon can be injected to make it an experimental electric furnacewith better safety.

Links:https://globefindpro.com/products/89450.html

-

Thermocouple

Thermocouple

-

High Precision Glass Cutting Machine

High Precision Glass Cutting Machine

-

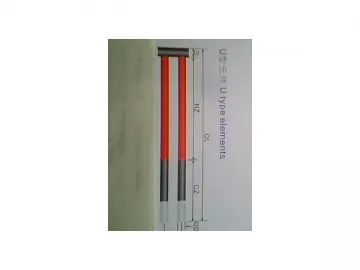

Silicon Carbide Rod

Silicon Carbide Rod

-

TIG-315 Industrial Inverter DC TIG Welding Machine

TIG-315 Industrial Inverter DC TIG Welding Machine

-

Electronic Ceramic Ignition Products

Electronic Ceramic Ignition Products

-

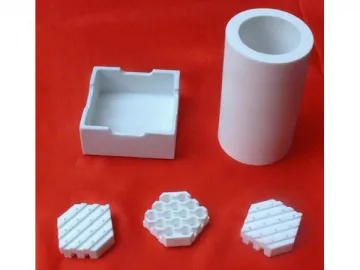

Insulating Brick, Refractory Brick, Crucible

Insulating Brick, Refractory Brick, Crucible

-

TIG-400II Industrial Inverter DC TIG Welding Machine

TIG-400II Industrial Inverter DC TIG Welding Machine

-

TIG-315II Industrial Inverter DC TIG Welding Machine

TIG-315II Industrial Inverter DC TIG Welding Machine

-

Fuel Gas Decorating Ceramic Kiln

Fuel Gas Decorating Ceramic Kiln

-

Lift Type Experimental Electric Furnace

Lift Type Experimental Electric Furnace

-

Quartz Tube, Stainless Steel Heat Pipe

Quartz Tube, Stainless Steel Heat Pipe

-

Ceramic Floor Tile Fuel Gas Tunnel Kiln

Ceramic Floor Tile Fuel Gas Tunnel Kiln