Gantry CNC Plasma and Flame Cutting Machine

GantryCNC Plasma and Flame Cutting Machine

The gantry CNC plasma and flamecutting machine are widely applied to the cutting of shipbuilding industry,steel structure, pressure vessel and various metallic plates in mechanicalindustry. Its high automation and cutting precisionsave the human resources and improve the working efficiency, which makes itsuitable for industrial and mining enterprises.

In terms of the low power CNC plasma and flame cutting, we recommend the lightgantry rack with square structure, whose mature design comes from our Koreanpartnership. Our engineering technicians have designed the box-girder gantrycutting rack based on the technology of Germany cutting machine. Its excellentrigidity and stability is fit for the cutting of high power CNC plasma andlaser fine plasma.

Our gantry CNC plasma and flame cutting machine has many advantages. Thecutting machine’s broad box-girder design ensures its rigidity and dynamicstability. It also has the advantage of elegant structure, small inertia andsmooth running. Its rack is treated by furnace annealing and fine processing.Besides, electrical, mechanical and pipeline system is specially protected,thus ensuring a longer life span of the machine. The running precision of thecutting machine is guaranteed by the AC servo drive system from Panasonic andreduction gears from SHIMPO and NEUGART. The adoption of integrated circuitsPLC control panel improves the flexibility of the machine and simplifies its electrical controlling system.

Besides, its CNC comes from the top grade brand of American HYPERTHERM andBURNY, and CNC system is stable and efficient. Besides, its plasma power fromHYPERTHERM, THERMADYNEMIC and KJELLBER can be adjusted according to the actualcutting needs. The plasma dust can be cleared with the method of tank-water, water bed and induced draft. The CNC system box and electric cabinet canbe added to the industrial air conditioner according to the climate of itslocation. It can ensure the cutting system runs regularly in hot and humidenvironment. And the cutting machine hasachieved 9 national patented technologies and is incompliance with CE, which is in line with the standard precision of GermanDIN2310.

Parameters of Gantry CNC Plasma and FlameCutting Machine

A.Gantry rack with light square tubes, suitable to low power plasma and flamecutting with span between 2.5-4.5 meters.

| Items | Specifications | ||||

| Model | GSD-2500II | GSD-3000II | GSD-3500II | GSD-4000II | GSD-4500II |

| CNC System | Micro-EDGE Pro, BURNY DAGGER NC, FastCNC | ||||

| Drive Way | Double servo drive | ||||

| Servo System | Japanese Panasonic( 400W, 750W, 1000W, 1500W ) | ||||

| Gear Reducer | Japanese SIMPO and German NEUGART | ||||

| Gas Hose | Italian FITT | ||||

| Magnetic Valve | Italian CEME | ||||

| CNC Torch | 1 or 2 sets of Hypertherm, 1 or 2 sets of flame torch, optional | ||||

| Cutting Thickness | 2 sets of torch: 6-150mm | ||||

| Cutting Speed | 50-550mm/min | ||||

| Arc Voltage THC | US Hypertherm Sensor-THC, Chinese XPTHC-100III | ||||

| Plasma Power | US Hypertherm PMX series | ||||

| PMX45 | PMX65 | PMX85 | PMX1650 | MAX200 | |

| Plasma Piecing Thickness | ≤6mm | ≤10mm | ≤10mm | ≤12mm | ≤25mm |

| Edge Cutting Speed | ≤10mm | ≤12mm | ≤16mm | ≤19mm | ≤50mm |

| Plasma Cutting Speed | 0-6000mm/min | ||||

| Machine Idle Speed | ≤12000mm/min | ||||

| Gantry Span | 2500mm | 3000mm | 3500mm | 4000mm | 4500mm |

| Cutting Width | ≤1600mm | ≤2100mm | ≤2600mm | ≤3100mm | ≤3600mm |

| Standard one flame one plasma, N sets of torch are added, standard width -200N (mm) | |||||

| Standard Rail Length | 12000mm, optional | ||||

| Cutting Length | ≤Standard rail length -2500 (mm) | ||||

| Cutting Quality | JB/T10045.4-1999 and German DIN2310 standard | ||||

B. Germany box-girder gantry rack, suitable to high power plasma and laser finplasma cutting.

| Items | Specifications | ||||

| Model | GSD-4000II | GSD-5000II | GSD-6000II | GSD-7000II | GSD-8000II |

| CNC System | US Hypertherm EDGE Pro, Micro-EDGE Pro, US BURNY 10LCD, DAGGER NC | ||||

| Drive Way | Double servo drive | ||||

| Servo System | Japanese Panasonic( 400W, 750W, 1000W, 1500W ) | ||||

| Gear Reducer | Japanese SIMPO and German NEUGART | ||||

| Gas Hose | Italian FITT | ||||

| Magnetic Valve | Italian CEME | ||||

| CNC Torch | 1 or 2 sets of Hypertherm, 1 or 2 sets of flame torch, optional | ||||

| Cutting Thickness | 2 sets of torch: 6-150mm | ||||

| Cutting Speed | 50-550mm/min | ||||

| Arc Voltage THC | US Hypertherm Sensor-THC, ArcGlide-THC, Chinese XPTHC-100III | ||||

| Plasma Power | US Hypertherm HPR series, US Thermadyne Ultra-Cut series | ||||

| HPR130xd | HPR260xd | HPR400xd | HPR800xd | Ultra-Cut | |

| Plasma Piecing Thickness | ≤16mm | ≤32mm | ≤38mm | ≤75mm | ≤40mm |

| Edge Cutting Speed | ≤38mm | ≤64m | ≤80mm | ≤160mm | ≤75mm |

| Plasma Cutting Speed | 0-6000mm/min | ||||

| Machine Idle Speed | ≤12000mm/min | ||||

| Track Gauge | 4000mm | 5000mm | 6000mm | 7000mm | 8000mm |

| Cutting Width | ≤3100mm | ≤4100mm | ≤5100mm | ≤6100mm | ≤7100mm |

| Standard one flame one plasma, N sets of torch are added, standard width -200N (mm) | |||||

| Standard Rail Length | 12m, optional | ||||

The gantry CNC flame cutting machine is your ideal choice, since the cutting ofpanels is the primary process of welding product. There are five modelsprovided for the series and they all adopt the gantry mechanical structure. The structure is applicable to cut large workpiece, and gantry CNC flame cutting machine has amaximum 7100mmcutting breath and maximum 11750mmlength. The double-sided driving makes the cutting machine move along the X andY axis on the fixed guide rail and landscape beam. The cutting machine has twotypes, flame and plasma, which can be converted freely. Compared with singleflame cutting equipment, with 50-750mm/min cutting speed or plasma weldingequipment, 0-6000mm/min,the function of flame plasma cutting machine is complete and can be used in anextensive application field.

Links:https://globefindpro.com/products/90689.html

-

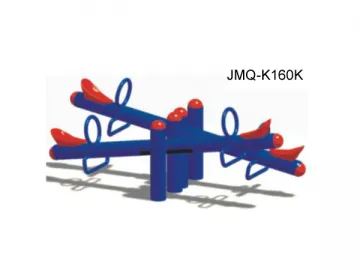

Amusement Rides, Seesaw

Amusement Rides, Seesaw

-

Brazing Furnace

Brazing Furnace

-

Safety Floor Mat

Safety Floor Mat

-

Bumper Car

Bumper Car

-

Indoor Playground Equipment

Indoor Playground Equipment

-

T10 LED Fluorescent Tube

T10 LED Fluorescent Tube

-

3 Phase DC Inverter CO2/Metal Active Gas Welding Machine

3 Phase DC Inverter CO2/Metal Active Gas Welding Machine

-

WED-M1V Veterinary Ultrasound Scanner

WED-M1V Veterinary Ultrasound Scanner

-

FDC8000 Color Doppler Ultrasound System

FDC8000 Color Doppler Ultrasound System

-

Member Card

Member Card

-

Bridge Multi-blade Block Cutter

Bridge Multi-blade Block Cutter

-

Irregular Shape Card

Irregular Shape Card