Vibration Feeder

Vibration Feeder

The vibration feeder can feed materialscontinuously and evenly and also pre-classify and screen the materials inindustries such as sand making, mining, building material production, chemical,metallurgy, and water conservancy industries. With dual functions, thevibration feeding equipment is provided with stable and high feeding efficiencyand safety operation. The additional material classification and screeningfunction makes the vibration feeder spacesaving and energy saving when used as a part of a complete stonecrushing screening machine.Additionally, the feeding equipment features stable and low noise operation,light weight, and low energy consumption, and its excitation force isadjustable to suit customers’ demands.

While being used for material dosing, the vibration feeder should be installedhorizontally to ensure steady and uniform material feeding and also avoidmaterial to flow by itself to ensure feeding precision. While being used forgeneral purpose continuous material feeding, the vibration feeder can beinstalled with a downward inclination angle of 10°. It can even be installedwith a downward inclination angle of 15° when it is used for feeding viscositymaterials or materials with high water content.

Technical Parameters of the VibrationFeeder

| Model | Funnel Size (mm×mm) | Max. Feed Size (mm) | Feeding Capacity (t/h) | Motor Power (kw) | Weight (kg) | Dimension (mm) |

| GZD-800×3000 | 800×3000 | 400 | 80-120 | 2.2 | 3195 | 3110×1800×1600 |

| GZD-960×3800 | 960×3800 | 500 | 120-210 | 2.2×2 | 3375 | 3850×1950×1630 |

| GZD-1100×4200 | 1100×4200 | 580 | 200-430 | 3.7×2 | 4400 | 4400×2050×1660 |

| GZD-1100×4900 | 1100×4900 | 580 | 280-500 | 5.5×2 | 4675 | 5200×2050×1700 |

| GZD-1300×5200 | 1300×5200 | 650 | 450-600 | 7.5×2 | 5400 | 5200×2350×1750 |

| ZSW-950×3800 | 950×3800 | 500 | 96-160 | 11 | 4100 | 3882×2224×2121 |

| ZSW-1100×4200 | 1100×4200 | 580 | 120-240 | 15 | 4745 | 4310×2500×1365 |

| ZSW-1100×4900 | 1100×4900 | 580 | 120-280 | 15 | 5420 | 4957×2500×1365 |

| ZSW-1100×5900 | 1100×5900 | 630 | 160-350 | 22 | 6100 | 6000×2500×2150 |

| ZSW-1300×5900 | 1300×5900 | 630 | 250-400 | 37 | 6300 | 6000×2700×2150 |

Working Principle

The vibration feeder ismainly composed of a feeding funnel, vibrator, spring support, driving systemand motor. The vibrator is composed of two eccentric shafts whose gears arejogged. While installation, the gears have to be jogged according to the signon them. Through motor driven, the two shafts start rotating to generate largelinear excitation force which forces thevibration feeder to vibrate. Due to the vibration, materials will slipand sling on the funnel and moves forward. Due to the screen on the funnel,fine material particles fall down directly to skip the crushing process in aproduction line. This is how the vibration feeder achieves its feeding and screeningfunctions.

Links:https://globefindpro.com/products/90841.html

-

ESYS-6014 Sound Pen

ESYS-6014 Sound Pen

-

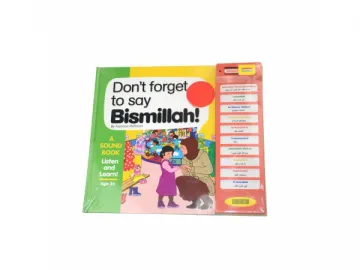

ESYS-3001 Education Sound Book

ESYS-3001 Education Sound Book

-

ESYS-4002 Dancing Plush Toy Module /Dancing Doll Module

ESYS-4002 Dancing Plush Toy Module /Dancing Doll Module

-

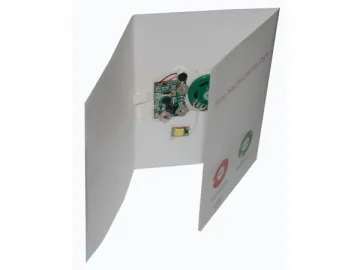

ESYS-6011 Personalized Musical Greeting Card

ESYS-6011 Personalized Musical Greeting Card

-

ESYS-1024 Mega Sounds Panel for Pre-School Education

ESYS-1024 Mega Sounds Panel for Pre-School Education

-

ESYS-6004 LED Keychain

ESYS-6004 LED Keychain

-

ESYS-3003 Custom Voice Book

ESYS-3003 Custom Voice Book

-

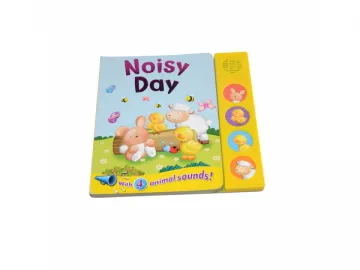

ESYS-3004 Audio Book

ESYS-3004 Audio Book

-

ESYS-4001 Music Dancing Movement Dolls /Sound Plush Toys

ESYS-4001 Music Dancing Movement Dolls /Sound Plush Toys

-

ESYS-5004 LED Display Module

ESYS-5004 LED Display Module

-

Rotary Magnetic Drum

Rotary Magnetic Drum

-

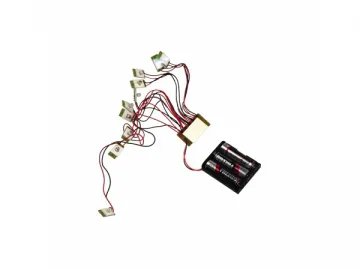

ESYS-1001 Sound Module Box

ESYS-1001 Sound Module Box