Shipbuilding

Shipbuilding

Our steel grit is ideal for use in shipbuildingindustry. It is used in sand blasting treatment process to help remove theoxide layer on ship body, so as to improve spray finishing quality.

The quality of steel grit determines the protective coating quality for ships.Hence, increased attention is paid to steel grits. Our steel grit was put intomarket in later half year in 2010, and in a year’s time, it has been highlyrecognized by over 20 large and medium sized shipbuilding enterprises andChinese famous coating service suppliers. According to users’ feedbacks, it isproven that our alloyangular steel grit has higher quality and helps ensure less loss and bettercoating quality, as compared with traditional cast steel grit. Currently,DUOLENG steel grit has been theoptimum grinding material solution.

Advantages of DUOLENG steel grit

1. High performance price ratio

We at DUOLENG have large production capacity, and we acquire raw materials fromChinese large sized suppliers directly. These, coupled with our automaticproduction processes, greatly reduce our production cost. Hence, we can offerour steel grit at competitive prices to shipbuilding enterprises and coatingservice suppliers.

2. Improved grit blasting cleanness

DUOLENG manufacture our steel grit with particle sizes in line with SAEJ827standard. The precision controlled sizes of the steel grits allow users tocontrol the grit blasting roughness easily and can help avoid second time gritblasting.

3. Reduced consumption rate

Our steel grit comes with good metallographic structure, uniform hardness, longanti-fatigue life, and high impact and wearing resistance, etc. This allows itto be recycled, help users to save steel grit consumption by 30%.

4. Improved working efficiency by energy and labor cost saving

The angular structure of our steel grits can not only improve the grit blastingsurface cleanness, but also increase equipment and workers’ working efficiencyby 30%. Meanwhile, it can help reduce equipment operation time and workers’working time, thus saving on energy consumption and labor cost further.

5. Reduced dust pollution

Our steel grit comes in forged state, and contains precious metal chromiumwhich offers it good impact resistance. This helps reduce dust pollution by30%, which can help ensure the smooth and safe operation of electricalmachines, extend the service time of equipment, and operator and workers’health.

Links:https://globefindpro.com/products/91583.html

-

Wooden Playground

Wooden Playground

-

Solar Water Heater

Solar Water Heater

-

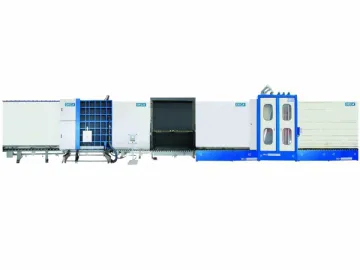

2700 Insulating Glass Production Line

2700 Insulating Glass Production Line

-

Multithread Flame Cutting Machine

Multithread Flame Cutting Machine

-

Domestic All in One Hot Water Air Source Heat Pump

Domestic All in One Hot Water Air Source Heat Pump

-

Solar Collector

Solar Collector

-

Allicin 15%, 25%

Allicin 15%, 25%

-

Straightening Machine

Straightening Machine

-

Feed Grade Yeast Powder 45%, 50%, 55%, 60%

Feed Grade Yeast Powder 45%, 50%, 55%, 60%

-

Metal Deck Roll Forming Machine

Metal Deck Roll Forming Machine

-

P3 Indoor Full Color LED Display Screen

P3 Indoor Full Color LED Display Screen

-

Steel Floor Deck Roll Forming Machine

Steel Floor Deck Roll Forming Machine