Steel Floor Deck Roll Forming Machine

SteelFloor Deck Roll Forming Machine

The YXOOKM51-305-914 steel floor deck roll formingmachine can produce steel floor deck of high strength, large working load, no deformation, and clean cuttingcross section. As compared with similar products of our competitors, our steelfloor deck roll forming machine offers advantages of smooth operation and highprecision manufacturing.

Structure steel is elongated by the strong forcebetween rollers after the structure steel is heated several times, and thendifferent kinds of steel floor deck can be formed. Steel floor deck can be usedas a template for casting concrete, thus eliminating the need for temporarytemplates and reducing production cost. In addition, it is convenient torestore, transport, and install steel floor deck, which reduces the amount oflabor involved. A high efficiency hydraulic motor is used to provide enoughpower for the hydraulic system to easily cut workpieces. Our reliable PLC control systemfrom Japanese Omron also provides the steel floor deck roll forming machinewith advantages such as automatic punching, cutting, and a high degree ofautomation.

Theexcellent performance of our floor decking roll forming machine is attributableto our high quality design, machine parts, and accessories. The machine’s standis made of H steel and is manufactured by milling 14mm thick plate, thus the rigidity and stability ofthe steel floor deck roll forming machine is ensured. The uncoiler has a load bearingcapacity of 5 tons. A guiding block is used to ensure that workpiece moves in the straightline. The cutter is made of Cr12 and undergoes heat treatment in order toachieve a hardness ranging from 58° to 62°. The roller is made of 45#steel and is coated with a 0.05mm thick layer of chromium. Therefore, anti-corrosion ability is improved, and thefloor decking roll forming machine service life is extended. A frequencyconverter from Taian also contributes to fastand reliable speed regulation. Convenient and automatic control is possiblewith the help of a computer which displays text.

1.Steel Floor Deck Picture

Main Specifications

| Type | YX51-305-914 | Application | ||

| Effective Width (mm) | 914 | |||

| Feeding Width (mm) | 1180 | |||

| Thickness (mm) | 0.8 | 1.0 | 1.2 | Steel Floor Deck |

| Section Inertia (cm4/m) | 91.62 | 119.38 | 142.01 | |

| Section Resistance (cm3/m) | 23.46 | 30.61 | 36.98 | |

2. Technical Specifications of Steel Floor Deck RollForming Machine

| Forming type | Simultaneous forming | |

| Guide Rod | mm | φ 50 |

| Bearing Guide | mm | φ 40 |

| Shaft | mm | φ 70 |

| Motor Power of Machine | kW | 18.5 |

| Linear Speed | mm/min | 10000-12000 |

| Motor of Hydraulic Station | kW | 4 |

| Number of Stations |

| 27 |

| Rolling Thickness | mm | 0.8-1.2 |

| Material Uncoiling Width |

| 1000 |

| Cut-to-length Accuracy | mm | ± 1.5 |

| Overall Dimensions(L×W×H) | mm | 26000×1400×1400 |

| Weight | kg | 18000 |

Weare a China-based steel floor deck roll forming machine manufacturer andsupplier. In addition to the rollforming machine, we also offer a purlin forming machine, H-beam steel production line, CNC cutting machine, and muchmore.

Links:https://globefindpro.com/products/91574.html

-

P3 Indoor Full Color LED Display Screen

P3 Indoor Full Color LED Display Screen

-

Metal Deck Roll Forming Machine

Metal Deck Roll Forming Machine

-

Feed Grade Yeast Powder 45%, 50%, 55%, 60%

Feed Grade Yeast Powder 45%, 50%, 55%, 60%

-

Straightening Machine

Straightening Machine

-

Allicin 15%, 25%

Allicin 15%, 25%

-

Shipbuilding

Shipbuilding

-

Rear Corner Post Inner

Rear Corner Post Inner

-

Steel Shot

Steel Shot

-

EPS Sandwich Panel Production Line

EPS Sandwich Panel Production Line

-

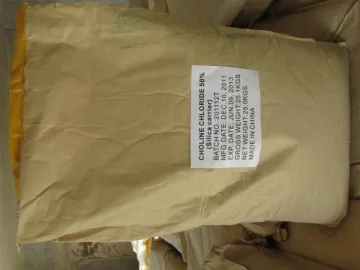

Choline Chloride 50%,60% Vegetable Carrier

Choline Chloride 50%,60% Vegetable Carrier

-

Hairdesign Power Hair Molding Clay

Hairdesign Power Hair Molding Clay

-

Choline Chloride 50% Silica Carrier

Choline Chloride 50% Silica Carrier