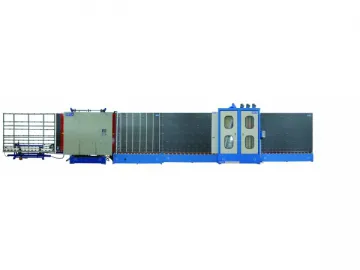

2700 Insulating Glass Production Line

AUTO STEP2700 Vertical insulating glass on-line gas filling and aircushion conveyor production line

AUTO STEP2700 Vertical insulating glass on-line gas filling and aircushion conveyor production line is applied to wash and dry glass,mount aluminum frame, automatically assemble and press glass, lay flat andconvey glass, etc., and can be used in producing normal IGU, Low-E IGU,extended IGU, triple IGU, Stepped IGU, Shaped IGU, etc. This insulating glassproduction line adopts double glazing techniques and automatic operation. It iscomposed of seven parts, including the vertical conveyer, washing and dryingstation, conveyer, inspecting and assembly section of aluminum frame, conveyorbefore pressing robot, pressing robot, and output conveyer.

Technical features

1) The insulating glass production line adopting advanced Germanytechnology and main components of international famous brands features reliableperformance and powerful function.

2) The air cushion working mode well protects the glass, making theproduction line clean and free from contamination and the best solution forhigh-level glass processing.

3) The online gas filling systemoffers high speed, high efficiency, and good gas filling effect.

4) All electrical equipment andsoftware of this insulating glass production line adopts Germany Siemensoriginal control system with humanization and professional design, convenientoperation and reliable performance.

5) The insulating glassproduction line is equipped with safe and reliable buffer section and inductionsystem connected with whole machine to monitor glass.

6) The roller wheels rolling withfriction force can transmit glass steadily and wear little.

7) This insulating glassproduction line can automatically identify the coating of glass, so it can beused to wash different kinds of glasses by controlling the rotating speed ofbrushes.

8) The Low-E brushes used for Low-e glass can rotate steadily in ahigh speed. The separate washing and rinsing cycle system of the insulatingglass production line is environmentally friendly and energy saving. Thespecially designed air-knife guarantees soonest drying effect.

9) The advanced frame mountingand assembly system makes precise frame positioning possible.

10) Theconveyor before pressing robot equipped with automatic identification system ofglass thickness and frame width can automatically detect and adjust thepressing pressure and distance to assemble precisely.

11) Thepressing robot of the insulating glass production line adopts Germanytechnology with unique vacuum system to ensure the reliable and steady suctionof different size of glass, and the guide screw together with the linear guideservo control system to ensure the precision location and assembly.

Technical Parameters of the InsulatingGlass Production Line

| Glass processing dimension | Once press | Min. | 190*350mm | |

| Max. | 2700*3500mm | |||

| Twice press | Max. | 2700*5000mm | ||

| Glass processing type | common glass and coating glass | |||

| Insulating glass thickness | 12-60mm | |||

| Single glass thickness | 3-15mm | |||

| Power supply | 380V/220V 50HZ | |||

| Voltage range | 6%—10% | |||

| Control voltage | 24V-DC | |||

| Electrical control system | Siemens PLC | |||

| Environment temperature | 15 ℃ -35 ℃ , as per DIN 40040 | |||

| Relative air humidity | ≤75%, as per DIN 40040 | |||

| Working height | 500±20mm | |||

| Angle of inclination | 6degree | |||

| Compressed air | 6.5bar | |||

| Water supply | min. 4.5bar | |||

| Distance from glass edge to frame | adjustable from 2 to 20mm | |||

| Conveyor speed | 48m/min | |||

| Working direction | left—right or right—left | |||

| Tilting table | Height | 850±20mm | ||

| Bearing | 1000kg & 250kg/m | |||

| Stepped IG | vertical distance | 2-50mm | ||

| Horizontal distance | 0-200mm | |||

| Total power | 51.7kw | |||

| Total weight | 8200KG | |||

As a specialized insulating glass production line manufacturer and supplier in China, DECAalso provides auto sealing robot, glass loading machine, glass edge deletionmachine, and CNC glass cutting machine, among others.

Links:https://globefindpro.com/products/91588.html

-

Multithread Flame Cutting Machine

Multithread Flame Cutting Machine

-

Domestic All in One Hot Water Air Source Heat Pump

Domestic All in One Hot Water Air Source Heat Pump

-

Solar Collector

Solar Collector

-

2000 Insulating Glass Production Line

2000 Insulating Glass Production Line

-

Tube Solar Water Heater

Tube Solar Water Heater

-

Insulating Glass Production Line

Insulating Glass Production Line

-

Solar Water Heater

Solar Water Heater

-

Wooden Playground

Wooden Playground

-

Shipbuilding

Shipbuilding

-

Allicin 15%, 25%

Allicin 15%, 25%

-

Straightening Machine

Straightening Machine

-

Feed Grade Yeast Powder 45%, 50%, 55%, 60%

Feed Grade Yeast Powder 45%, 50%, 55%, 60%