PTFE, FEP, PFA, PVDF Cable

PTFE, FEP, PFA, PVDF Cable

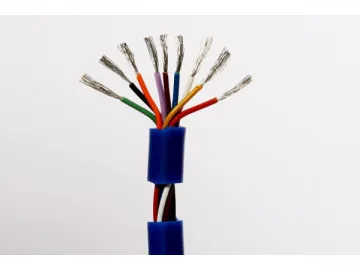

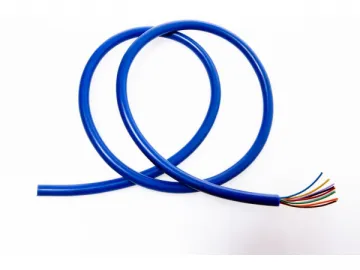

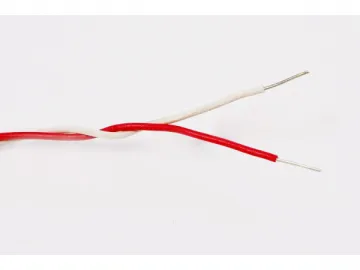

PTFE cables have outstanding mechanical and electrical properties and are used in many situations where temperatures are of 180°C and above or where temperatures are below Minus 40°C and in most adverse uses, where chemical fumes and liquids would render all other cables useless. PTFE is the most well known as durable polymer and has been used in the cable industry for many years. Its outstanding dielectric properties, even at elevated temperatures, make it most suitable for insulation of cables. Teflon insulated cables are resistant to fire, chemicals, sunlight, and is moisture resistant.

ETFE, FEP, and PFA cables have extended temperature-range resistance compared to PVC. FEP cables have some advantages, rated -80°C to 200°C to minimize stretching and cracking associated with extreme weather conditions when installing. It has an extremely low friction jacket for ease of routing, pulling through conduit and minimizing the possibility of jacket damage. It is impervious to all fuels, oils, solvents, acids, chemicals, sunlight and water. It is suitable for direct burial applications, and offers space savings for conduit.

Applications

PTFE, FEP, PFA, PVDF wire is used in instrumentation of power projects, chemicals, steel plants, military, aerospace, and various other types of engineering industries.

Links:https://globefindpro.com/products/93207.html