Single Layer Plastic Sheet Extruder

Single Layer Plastic Sheet Extruder

Model: ZHP-670B

Application

We adopt advanced international technology and make considerable innovations ondesign, manufacturing and accessories for the ZHP series plastics sheetextruder. The single layer plastic sheetextruder is used to produce plastic sheet of PP and PE. The sheet can thenbe taken to produce such items as disposable cups,jelly cups, plastic packing containers, files, and so on.

Technical Specifications of the Plastic SheetExtruder

| Model | ZHP-670B |

| Width of Die Head | 700mm |

| Material | PP.PE |

| Width of Sheet | 680mm |

| Three Roller Size | Ф350*700mm*3 |

| Thickness of Sheet | PP.PE:0.3-2.5mm |

| Screw Size | Ф110 1:32 |

| Total Power | 110kw |

| Working Power | 65kw |

| Speed | 15-20m/min |

| Capacity | 150kg /h |

| Dimension | 12*1.5*2.2m |

| Weight | 5200kg |

Features

1. The single layer plastic sheet extruderoffers hard gear, strong torque, and low noise.

2. The screw material is 38 crMoAL and thenitrogen treatment is 0.4 - 0.7mm.

3. It offers 5 heating zones of the screwand 3 heating zones of the die head.

4. It has a motor screen changer system.

5. The single layer plastic sheet extruderhas an individual 45° three roller control system.

6. It offers PID adjusting memory and anti-jam digital and temp. control.

7. It has full frequency conversion control (Danfoss).

8. It offers roller hard chromium plating 0.08-0.18mm, hardness: HRC58-62 andsurface

roughness: ≥Ra

9. The single layer plastic sheet extruder has an energy-saving die head.

10. It uses electric parts from CHINA Chint Electric.

Configuration List ofthe Extrusion Line

1. ∮110 type main extruder 1 piece

2. 120 type hydraulic screen changer 1 set

3. Waste rewinder 1 set

4. PP, PS die head 1 set

5. Inclined type 3-roll calender (with synchronous chain drive) 1 piece

6. Natural cooling system 1 set

7. Edge cutting device 1 set

8. Parallel winding machine 1 set

9. Electric cabinet 1 set

10. Automatic feeder 1 set

Customer to Provide

1. Water, oiland electricity supply

2. Make preparations for the extruder base position

3. Cables toconnect general power supply and electric cabinet

4. Media like oil, and materials for startingand operating the equipment, etc.

This list and picture is forinformation only. Please take the actual product as standard!

Specificdesign for special demand can be made according to requirement.

As a specialized singlelayer plastic sheet extruder manufacturer based in China, we not only provide sheetextruder, but also cup printing machine, laminating machine, thermoformingmachine, and much more.

Links:https://globefindpro.com/products/93635.html

-

Plastic Crushing Machine

Plastic Crushing Machine

-

Plastic Thermoforming Machine

Plastic Thermoforming Machine

-

Double Layer Sheet Extrusion Machine

Double Layer Sheet Extrusion Machine

-

Plastic Sheet Extrusion Machine

Plastic Sheet Extrusion Machine

-

Plastic Mixing Machine

Plastic Mixing Machine

-

MK-425 Roller POS Cash Drawer

MK-425 Roller POS Cash Drawer

-

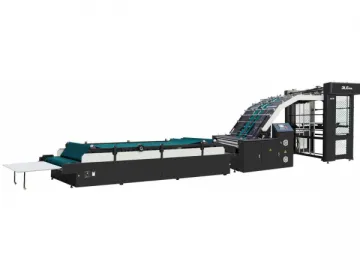

Flute Laminating Machine

Flute Laminating Machine

-

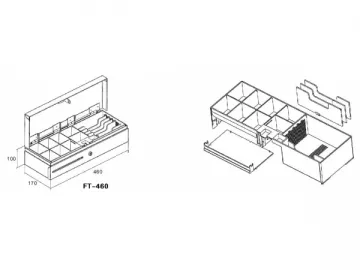

FT-460 Flip Top Cash Drawer

FT-460 Flip Top Cash Drawer

-

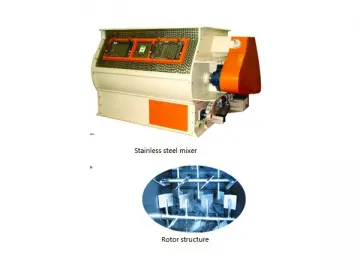

Double Shaft Paddle Feed Mixer

Double Shaft Paddle Feed Mixer

-

Nursery Crate

Nursery Crate

-

Drop Shape Hammer Mill

Drop Shape Hammer Mill

-

Pneumatic Slide Gate, Electrical Slide Gate

Pneumatic Slide Gate, Electrical Slide Gate