Double Layer Sheet Extrusion Machine

Double Layer Sheet Extrusion Machine

Application

We adopt advanced international technology and makeconsiderable innovations on design, manufacturing and accessories for the ZHPseries plastics sheet extruder. The Double Layer Sheet Extrusion Machine is used toproduce two layers or three layers of plastic sheet of PP, PS and PE. The sheetcan then be taken to produce such items as disposable cups, jelly cups, plasticpacking containers, file, and so on.

TechnicalSpecifications of the Double Layer Sheet Extrusion Machine

| Model | ZHP-800D | ZHP-1000D | ZHP-1200D |

| Width of Die Head | 800mm | 1000mm | 1200mm |

| Material | PP.PS.PE | PP.PS.PE | PP.PS.PE |

| Width of Sheet | 750mm | 900mm | 1000mm |

| Three Roller Size | Ф350*900mm*3 | Ф350*1100mm*3 | Ф350*1300mm*3 |

| Thickness of Sheet | PP.PE: 0.3-2.5mm PS: 0.15-2mm | PP.PE: 0.3-2.5mm PS: 0.15-2mm | PP.PE: 0.3-2.5mm PS: 0.15-2mm |

| Screw Size | Ф110 1:32 Ф80 1:30 | Ф110 1:32 Ф80 1:30 | Ф120 1:30 Ф80 1:30 |

| Total Power | 110kw | 120kw | 150kw |

| Working Power | 65kw | 72kw | 90kw |

| Speed | 15-20m/min | 15 - 30m/min | 15-50/min |

| Capacity | 200kg/h | 250kg/h | 320kg/h |

| Dimension | 12*1.8*2.2m | 12*2.0*2.5m | 11.5*2.2*2.5m |

| Weight | 6600kg | 7500kg | 8000kg |

Features

1. The Double Layer Sheet Extrusion Machine offers hard gear, strong torque, and low noise.

2. The screw material is 38 crMoAL and the nitrogen treatmentis 0.4 – 0.7mm.

3. Screwwith air cooling system

4. 5 heating zones of the screw.

5. It offers anuninterrupted hydraulic screen changer system.

6. The Double Layer Sheet Extrusion Machine has an energy-saving die head with plating and polishing.

7. It has a synchronous 45° three roller control system.

8. It has full frequency conversioncontrol (Delta).

9. It offers a waste rewinding system.

10. The Double Layer Sheet Extrusion Machine offers moving with electromotion control system.

11. It has roller hard chromiumplating 0.08-0.18mm, hardness: HRC58-62 and surface roughness: ≥Ra.

12. Itoffers a double post gantry traction rewinding system.

13. The Double Layer Sheet Extrusion Machine has 4 heating zones of the die head.

14. It has an auto material feedingsystem.

15. It offers Omron Temp.Controller PID Adjusting, memory and anti-jam digital temp. control.

16. Electric parts of Schneider Electric are used for the extrusion machine.

Customer to Provide

1. Air, water, oil and electric

2. Connectioncable

This list and picture is for information only. Pleasetake the actual product as standard!

Specific design forspecial demand can be made according to requirement.

We are a Double Layer Sheet Extrusion Machine manufacturerbased in China.We provide various types of products such as double layer sheet extrusionmachine, flute laminating machine, and six color offset printing machines.

Links:https://globefindpro.com/products/93640.html

-

Plastic Sheet Extrusion Machine

Plastic Sheet Extrusion Machine

-

Plastic Mixing Machine

Plastic Mixing Machine

-

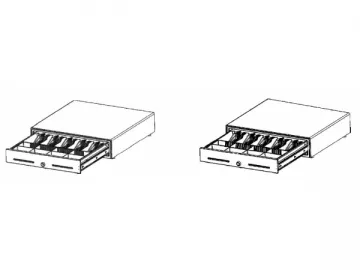

MK-425 Roller POS Cash Drawer

MK-425 Roller POS Cash Drawer

-

MS-102 POS Safe

MS-102 POS Safe

-

Single Layer Plastic Sheet Extrusion Machine

Single Layer Plastic Sheet Extrusion Machine

-

SK-480 Slide POS Cash Drawer

SK-480 Slide POS Cash Drawer

-

Plastic Thermoforming Machine

Plastic Thermoforming Machine

-

Plastic Crushing Machine

Plastic Crushing Machine

-

Single Layer Plastic Sheet Extruder

Single Layer Plastic Sheet Extruder

-

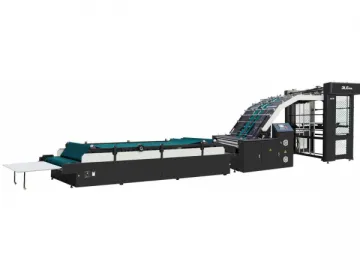

Flute Laminating Machine

Flute Laminating Machine

-

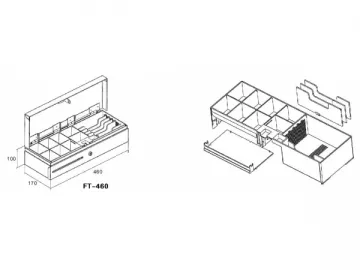

FT-460 Flip Top Cash Drawer

FT-460 Flip Top Cash Drawer

-

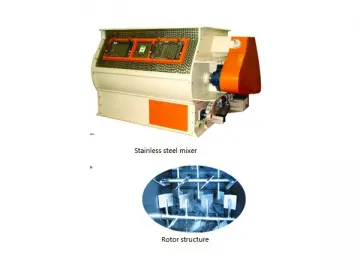

Double Shaft Paddle Feed Mixer

Double Shaft Paddle Feed Mixer