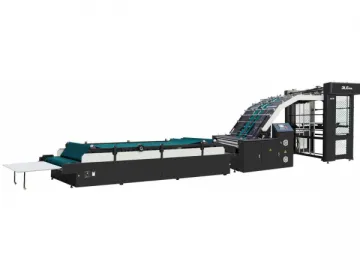

Plastic Sheet Extrusion Machine

Plastic Sheet Extrusion Machine

Application

We adopt advanced international technology and makeconsiderable innovations on design, manufacturing and accessories for the ZHPseries plastics sheet extruder. The Plastic Sheet Extrusion Machine is used to produce two layersor three layers of plastic sheet of PP, PS and PE. The sheet can then be takento produce such items as disposable cups, jelly cups, plastic packingcontainers, file, and so on.

Technical Process

Feeding – Heating – Filtrating – Extruding

Technical Parameters of the Sheet ExtrusionMachine

1. Double layer sheet

2. Material: PP PS PE

3. Error of thickness: ±0.01mm

Configuration

| Appellation | Data | Origin | Note |

| Main Frequency Motor | 55KW 6 Level | Domestic | 4-gear, rotary speed: 980r/min |

| Accessorial Frequency Motor | 22KW 6 Level | Domestic | 4-gear, rotary speed: 980r/min |

| Barrel Heaters | Aluminum heater with air blower | ||

| Gear Box | 280 type | Domestic | Hard gear, strong torque, low noise |

| Transducer | 55kw and 22kw | Domestic | |

| Temperature Controller | XMTE-6411 | Japan | Intelligent PID |

| Screen Changer | 120 type | Domestic | Uninterrupted hydraulic |

| Die Head | 1000mm | Domestic | Heat inside, plating, polishing |

| Three Rollers | Diameter: 350mm Width: 1000mm | Domestic | Plating and mirror handling |

| Waste Rewinding | Double posts | Domestic | |

| Rewinding System | Domestic | Double post rewind |

4. Sheet width: ≥900mm

5. Sheet thickness: PP: 0.3-3mmPS: 0.15-2mm

6. Capacity: ≤350kg/h

7. Speed: 2.5m-26m/min

8. Total Power: 145kw

9. Work Power: 90kw

10. Machine Dimension: 13m*2.5m*2.5m

11. Machine Weight: ≈ 7.5t

Main Parts of theSheet Extrusion Machine

1. Feeding system

2. 110, 65 Screw

3. Hydraulic screen changer

4. Clothes rack type die head

5. Individual three rollers

6. Traction system

7. Rewinding system

8. Cutting and counting system

9. Electric assembly

Technical Specifications of the Plastic Sheet Extrusion Machine

1. Automaterial feeding system: 2.2kw; ≤500kg/h

2. Screw: Diameter: Ф110mm& 65mm

L/D rate: 1:32 and 1:30

Screw material: 38 crMoAL

Nitrogen treatment: 0.4 - 0.7mm

3. Three Rollers

Size: Ф350mm*1000mm 2pcs and 400mm*1000mm 1pc

Hard chromium plating: HV850—920

Thickness of hard chromium: 0.08-0.18mm

Hardness: HRC58-62

Surface roughness: ≥Ra

Drive by Individual 2.2 kw frequency motor

Customer to Provide

1. Air, water, oil and electric

2. Connection cable

This picture is for reference only. Please take the actual product asstandard!

Wylong is a specialized Plastic Sheet Extrusion Machine manufacturer and supplier based in China.We also provide laminating machine, cup printing machine, thermoformingmachine, and much more

Links:https://globefindpro.com/products/93641.html

-

Plastic Mixing Machine

Plastic Mixing Machine

-

MK-425 Roller POS Cash Drawer

MK-425 Roller POS Cash Drawer

-

MS-102 POS Safe

MS-102 POS Safe

-

Single Layer Plastic Sheet Extrusion Machine

Single Layer Plastic Sheet Extrusion Machine

-

SK-480 Slide POS Cash Drawer

SK-480 Slide POS Cash Drawer

-

Cup Stacking Machine

Cup Stacking Machine

-

Double Layer Sheet Extrusion Machine

Double Layer Sheet Extrusion Machine

-

Plastic Thermoforming Machine

Plastic Thermoforming Machine

-

Plastic Crushing Machine

Plastic Crushing Machine

-

Single Layer Plastic Sheet Extruder

Single Layer Plastic Sheet Extruder

-

Flute Laminating Machine

Flute Laminating Machine

-

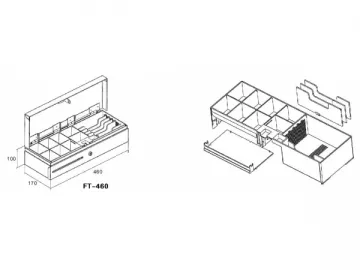

FT-460 Flip Top Cash Drawer

FT-460 Flip Top Cash Drawer