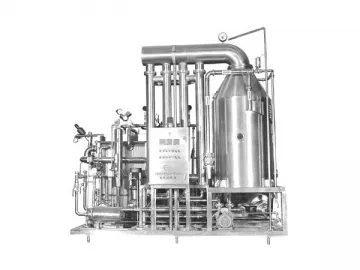

Flash Evaporation Degassing Machine

Flash Evaporation DegassingMachine

Applications

XZT flash evaporationdegassing machine is an automatic control system designed for use in milk orother related material evaporation. Take milk evaporation and degassing as anexample. In general, the milk is put into the vacuum container and heated bythe plate-type heat exchanger of the evaporation degassing machine. In thisway, the water in milk is evaporated. Then the steam is cooled in the pipe-typeheat exchanger. After going through such a process for about five times, thewater in milk is evaporated enough, and the milk is hence degassed fully.

Technical Specifications of the Flash Evaporation Degassing Machine

| Outlet capacity | 2000-15000kg/h | Product discharging temperature | 60 ℃ |

| Evaporation capacity | 13 % --15.4 % | Feeding and discharging of cooling water | 4 " |

| Inlet capacity | Outlet capacity 15 % | Temperature of cooling water | Max . 35 ℃ |

| Feeding/discharging temperature | 80 ℃ /60℃ | Water feeding diameter | 1 " |

| Cooling water | 100t/h at 30 degree | Conditioning air feeding diameter | 1 " |

| Steam consumption | 1500-4000kg/h,5bar | Steam feeding diameter | DN50 |

| Temperature of hot water | 82-90℃ | Compressed air consumption | φ6mm |

| Product feeding diameter | 2 " at 5bar | Power supply | 3*400VAC |

| Product discharging diameter | 2 " | Power capacity/consumption | 30-80KW |

| Product feeding temperature | 80 ℃ |

As a flash evaporation degassingmachine manufacturer and supplier in China, our company also providesliquid deaerator, UHT milk tubular sterilizer, creamseparator, spray tunnel sterilizing machine, and others.

Links:https://globefindpro.com/products/93834.html

-

Yoghurt Tubular Sterilizer

Yoghurt Tubular Sterilizer

-

Juice, Tea Drink Sterilizer

Juice, Tea Drink Sterilizer

-

Intergrated CIP System

Intergrated CIP System

-

Tubular Sterilizer

Tubular Sterilizer

-

Soybean Milk Tubular Sterilizer

Soybean Milk Tubular Sterilizer

-

Milk Clarifier

Milk Clarifier

-

Liquid Deaerator

Liquid Deaerator

-

Ice Cream Plate Sterilizer

Ice Cream Plate Sterilizer

-

Lab Liquid Sterilizing Machine

Lab Liquid Sterilizing Machine

-

Ice Cream Processing Equipment

Ice Cream Processing Equipment

-

Water Bath Sterilizing Machine

Water Bath Sterilizing Machine

-

UHT Milk Tubular Sterilizer

UHT Milk Tubular Sterilizer