Auto-Abrasive Delivery System

Auto-Abrasive Delivery System

The cutting cost primarily depends on the consumption of abrasive. Optimizingabrasive feeding quantity is extremely important to the successful use of waterjet cutting. Researches indicate that abrasive ratherthan high pressure water provides more than 85% of cutting power, andtherefore, we at Teenking try our best to improve thecutting power and utilization of abrasive.

Generally, there are two major factors that affect the cutting power ofabrasive.

1. Higher pressure water provides bigger cutting power. (That’s why we increasethe water pressure to 380mpa or more.)

2. High pressure water with bigger flow rate generates larger cutting power.(That’s the reason we increase the horsepower of pumps and the diameter of nozzlesto obtain larger discharge of high pressure water.)

High pressure water is the carrier of abrasive, and water of high pressure andlarge flow rate can increase the cutting power of abrasive as it can carry moreabrasive for cutting. However, the maximal abrasive feeding quantity will notresult in the fastest cutting. On the contrary, too much abrasive will plug themixing tube due to accumulation, which not only wastes the abrasive but alsoreduces the cutting speed. Also, small quantity of abrasive will greatly reducethe cutting speed. In addition, it will increase the dependence of cutting onhigh pressure water, thereby increasing the wear of high pressure pumps.

An accurately automatic abrasive delivery system can greatly improve cuttingefficiency, save heavy abrasive feeding labor, and stabilize the abrasivefeeding process. Teenking auto-abrasive delivery system is such a product, which realizes smoothabrasive supply and removes problems such as abrasive blockage and abrasivesupply failure. With a capacity of 100L (can load 120kg of abrasive) or 200L (250kg),it can suit your different requirements. As the abrasive CNC feederprovides reliable performance, is easy to use and suitable for continuousoperation, it is the ideal abrasive delivery system for waterjetcutter users.

The abrasive delivery system is equipped with an abrasive empty alarm device(sound and lamp), an automatic air-water separator, an air pressure regulatorand an over-high air pressure relief safety device.

The working principle of the auto abrasive delivery system

1. The computersends pulses to control the stepper motor to generate the rotating speedrequired.

2. The stepper motor drives the abrasive feeding wheel to uniformlyrotate with different speeds so as to realize control of abrasive quantity byfeeding rate or directly compiling the information of abrasive quantity(rotating speed) into programs.

3. Theabrasive feeding rate is controlled by “abrasive valvecontrol” on the computer. You can also directly compile the information of theabrasive quantity (rotating speed) into the program for program-control of theabrasive quantity.

Teenking is an auto-abrasive delivery system manufacturer based in China. We primarily provide CNC waterjetcutting machine, water jet cutting machine pump, platform CNC waterjet cutting machine, waterjetgrinding head, 5 axis dynamic waterjet cuttingsystem, and waterjet engraving head.

Links:https://globefindpro.com/products/98430.html

-

Waterjet Cutting Machine Fan Cooling System

Waterjet Cutting Machine Fan Cooling System

-

Seamless Steel Pipe

Seamless Steel Pipe

-

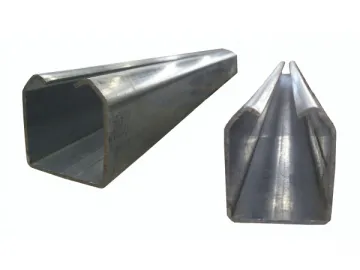

Tubing

Tubing

-

Roll Forming Equipment

Roll Forming Equipment

-

Casing Steel Pipe

Casing Steel Pipe

-

Cold Drawn Seamless Steel Pipe

Cold Drawn Seamless Steel Pipe

-

Waterjet Engraving Head

Waterjet Engraving Head

-

Water Cooled Deutz Engine Diesel Generator Set, D Series

Water Cooled Deutz Engine Diesel Generator Set, D Series

-

Air Dryer of Waterjet Cutting Machine

Air Dryer of Waterjet Cutting Machine

-

Waterjet Cutting Control System

Waterjet Cutting Control System

-

MTU Diesel Generator Set

MTU Diesel Generator Set

-

Water Cooled Deutz Engine Diesel Generator Set, BF Series

Water Cooled Deutz Engine Diesel Generator Set, BF Series