XH716 Vertical Machining Center

XH716 Vertical Machining Center

XH716 vertical machining center can be used in both rough machining and finishmachining applications, to meet your different machining requirements. Qualitybuilt and easy to use, it is widely used in the fields of machinerymanufacturing and mould making.

Features

1. The verticalmachining center adopts a high speed, high precision and high rigidity spindleunit and floating tool clamping system.

2. The machine body and main components are made using high strength cast ironwhich has stable metallographic structure. This contributes to maintaining thestability of the machining center.

3. Pre-stretch precision ball screw drive.

4. Oil/water separation design

5. Intermittent auto lubrication makes every point well lubricated.

6. XH716 vertical machining center uses 3-axisrectangular block guideway, and XHS716 vertical machining center adopts 3-axislinear rolling guideway.

MainAccessories

| Standard Accessories | Optional Accessories |

| 3-axis block guideway | The 4th-axis/The 5th-axis |

| FANUC 0i mate-MD CNC system | FANUC 0i Mc, Siemens 802DSL, HNC-21/22MD, GT-150im, Mitsubishi M 64SM CNC system |

| High precision and speed spindle unit (8000rpm) | Round plate type A.T.C with 24 tools capacity |

| Umbrella type A.T.C with 16 tools capacity | Spiral chip removal device |

| Floating tools clamping system. | Forceful cutting washing system |

| Separated type electronic handwheel | Oil cooling spindle |

| Standard exterior RS232 interface |

|

| Designing with oil and water separated. |

|

| Intermittent auto-lubrication system |

|

| Fully enclosed splash guard |

|

Main Technical Parameters of XH716 Vertical Machining Center

| Item | Unit | Technical parameters |

| X-axis travel | mm | 1000 |

| Y-axis travel | mm | 600 |

| Z-axis travel | mm | 500 |

| Distance from spindle nose to table | mm | 150-650 |

| Distance from spindle center to column guide-way face | mm | 655 |

| High speed feeding of X,Y axis | mm/min | 15000 |

| High speed feeding of Z axis | mm/min | 12000 |

| Feeding speed | mm/min | 1-5000 |

| Table size | mm | 600×1300 |

| Max. loading capacity of table | kg | 800 |

| T-slot NO./width/distance of table |

| 5/18/125 |

| Max. speed of spindle | r/min | 8000 |

| Main motor rated power | kw | 7.5/11 |

| Spindle nose taper |

| BT40 |

| Magazine capacity | pc | 16 |

| Magazine type |

| umbrella type |

| Max. diameter of tools | mm | ф80 |

| Max. length of tools | mm | 300 |

| Max. weight of tools | kg | 6 |

| Positioning accuracy | mm | 0.016 |

| Re-positioning accuracy | mm | 0.01 |

| Pneumatic pressure | mpa | 0.6 |

| N.W | kg | 6500 |

| Overall dimension | mm | 2920×2930×2530 |

As an experiencedvertical machining center manufacturer in China, LUNAN offers a comprehensiverange of products that includes horizontal machining center, CNC lathe,drilling milling machine, lathe, turret milling machine, CNC milling machine,and others.

Links:https://globefindpro.com/products/98548.html

-

ZX6350Z Drilling Milling Machine

ZX6350Z Drilling Milling Machine

-

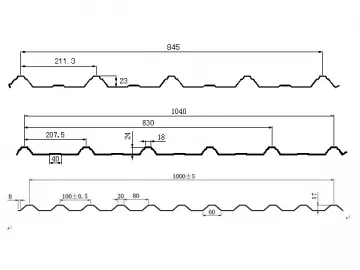

Corrugated Roof Panel Machine

Corrugated Roof Panel Machine

-

Roof Roll Forming Machine

Roof Roll Forming Machine

-

Ridge Roll Forming Machine

Ridge Roll Forming Machine

-

XH2412 Gantry Machining Center

XH2412 Gantry Machining Center

-

Roof Forming Machine

Roof Forming Machine

-

Color Roof Roll Forming Machine

Color Roof Roll Forming Machine

-

Hat and Keel Forming Machine

Hat and Keel Forming Machine

-

Metal Processing Machines

Metal Processing Machines

-

PU Foaming Machine

PU Foaming Machine

-

Sandwich Panel Machine

Sandwich Panel Machine

-

Steel Pipe Machine

Steel Pipe Machine