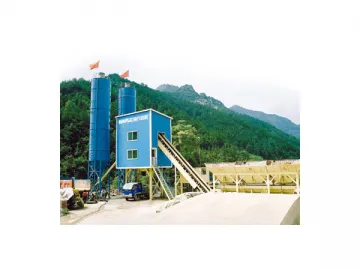

Ready-mixed Concrete Mixing Plant

Ready-mixedConcrete Mixing Plant

HYP Ready-mixed ConcreteMixing Plant

Leading New Mixing Concept

High efficiency/Low cost/Environmentalfriendly

Based on many years experience manufacturing concretemixing plants, WE researched and developed ready-mixed concrete mixing plant.

Concrete mixing plant or concrete batching plant is widely used in ready-mixedconcrete mixing, pipe pile, hydraulic engineering and many other mixing places.Our mixing plants are designed and manufactured according to differenttechnical requirements. Every set is very professional.

Technical features

Various kinds of compound modes

Core technology advantages

Green, environmental and energy-saving

Duplex computer controlsystem

Spiral mixing equipment

MY4000 double-horizontal-shaft mixing equipment

Conveyer system

Wet concrete separating and recycled reuse system

1. Various kinds of compoundmodes

Body structure: (single, double) station, (single, double) floor, boat, halftower type;

Concrete mixing: (new type) twin-spiral mixer, double-horizontal-shaft mixer;

Control system: (new type) duplex computer control system, classic controlsystem;

Aggregate conveying: (flat, zigzag, groove shape) charge hoisting by beltconveyor and by hoister;

Powder conveying: spiral conveying, air conveying and air duct conveying;

Material measurement: respective measurement and accumulated measurement;

Dedusting system: (cloth bag, vibrating, impulsetype) dedusting device;

Gaspath system: adopt world famous brands components;

Add-on systems

1) powdery additive: fan blade hopper, spiral type;

2) Recycling: sand and rock separator;

3) Ice weighing device: used for concrete mixing equipment.

4) Aggregate screening device: rolling type and flat vibrating type.

2. Core technologyadvantages

High storage sand and stone storage bin is locatedon the top floor. From measuring, mixing to discharging, all the processes arein a sealed environment to achieve environmental protection. It is suitable forready-mixed concrete, large-sized engineering project,cement component production place, etc.

3. Green,environmental and energy-saving

1.1 High quality,energy-saving, and environmental protective concrete mixing plant provides agreat guarantee to green concrete production.

1.2 Sealed sand weighing and conveying system can furthest reduce noisepollution.

1.3 Negative pressure dust remove cloth bag is used to solve the problem ofdust pollution. It is energy saving and environmental friendly.

1.4 Wet concrete separating and recycled reuse device, adopts three-dimensionalarrangement to form a set of sealed sewage treatment and sand(stone)recycling system. Therefore, the seriflux and wastecan be reused to achieve zero discharge. This device helps largely reduce theenvironmental pollution and save the energy.

4. Parameters of ready-mixedconcrete mixing plant

1. Parameters of HYP ready-mixed concretemixing plant

| Model | HYP60 | HYP90 | HYP120 | HYP180 | HYP240 | |

| Productivity(m3/h) | 60 | 90 | 120 | 180 | 240 | |

| Concrete mixer | Model | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 |

| Power(kW) | 2×18.5 | 2×30 | 2×37 | 2×55 | 2×75 | |

| Output(m3) | 1 | 1.5 | 2 | 3 | 4 | |

| Aggregate size (mm) | ≤80 | ≤100 | ≤120 | ≤150 | ≤150 | |

| Storage hopper capacity | 120 | 120 | 200 | 200 | 200 | |

| Belt conveyor capacity (t/h) | 200 | 300 | 400 | 500 | 600 | |

| Weighing scope | Aggregate (kg) | 2×1500 ±2% | 2×2000 ±2% | 2×2400 ±2% | 2×3600 ±2% | 2×4800 ±2% |

| Cement (kg) | 600±1% | 1000±1% | 1200±1% | 1800±1% | 2400±1% | |

| Coal ash (kg) | 200±1% | 300±1% | 400±1% | 600±1% | 800±1% | |

| Water(kg) | 300±1% | 500±1% | 600±1% | 800±1% | 1000±1% | |

| Admixture (kg) | 2×30±1% | 2×30±1% | 2×50±1% | 2×50±1% | 2×50±1% | |

| Total Power (kW) | 85 | 117 | 170 | 210 | 240 | |

| Discharging height (m) | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | |

Note

1. The power of screw conveyor is excluded fromthe total power;

2. The quantity and size of Aggregate hoppers are customizable;

3. The indicated above parameters may change without advance notice.

2. Parameters of HYMPready-mixed concrete mixing plant

| Model | HYMP 60 | HYMP 90 | HYMP 120 | HYMP 180 | HYMP 240 | |

| Productivity(m3/h) | 60 | 90 | 120 | 180 | 240 | |

| Concrete mixer | Model | JS 1000 | JS 1500 | JS 2000 | JS 3000 | JS 4000 |

| Power (kW) | 2×22 | 2×30 | 2×37 | 2×55 | 2×75 | |

| Output (m3) | 1 | 1.5 | 2 | 3 | 4 | |

| Aggregate size (mm) | ≤60 | ≤80 | ≤120 | ≤150 | ≤150 | |

| Stock bin | Size(m3) | 3×13 | 3×13 | 3×13 | 4×20 | 4×20 |

| Quantity | 3 | 3 | 3 | 4 | 4 | |

| Belt conveyor capacity (t/h) | 200 | 200 | 300 | 400 | 600 | |

| Weighing scope and precision | Aggregate (kg) | 2500 ±2% | 3500 ±2% | 4500 ±2% | 6500 ±2% | 9000 ±2% |

| Cement(kg) | 600 ±1% | 900 ±1% | 1200 ±1% | 1800 ±1% | 2400 ±1% | |

| Coal ash(kg) | 200 ±1% | 300 ±1% | 400 ±1% | 600 ±1% | 800 ±1% | |

| Water (kg) | 300 ±1% | 400 ±1% | 600 ±1% | 800 ±1% | 1000 ±1% | |

| Admixture (kg) | 10±1% | 30±1% | 30±1% | 50±1% | 50 ±1% | |

| Total power(kW) | 82 | 108 | 127 | 178 | 220 | |

| Discharging height (m) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | |

Note

1. The power of screw conveyor is excluded fromthe total power;

2. The quantity and size of Aggregate hoppers are customizable;

3. The indicated above parameters may change without advance notice.

4. Duplex computer control system

1) Advanced duplex computer control system

2) High performance hardware configuration to ensure stable and reliablecontrol.

1. Good industrial computer;

2. Mitsubishi PLC with high performance and long service life: high runningspeed and reliable performance;

3. Mitsubishi human-computer interface: Chinese language; wide visual angel;rapid response and reliable performance;

4. Mitsubishi AD module: switching speed: 500 μ s; resolution: 1/20000;

5. Schneider, ABB and OMRON low voltage apparatus are available in our concreteengineering equipments;

3) Perfect control function.

4) Convenient maintenance and simple operation.

5. Twin-spiral concrete mixer

1) Description

1. Double-horizontal shaft and twin-spiral mixing plant can meet differentmixture ratios depends on its excellent and efficient mixing performance.

2. Various models are available, single host can be configured to a set of 50~240m3/h concrete mixing plant.

3. They are suitable for concrete mixing of road, bridge, airport, cityconstruction and other ready-mixed concrete.

2) Excellent workability

1. To common concrete, twin-spiral mixer only needs 20 seconds to achieve equalmixing; to high performance concrete, it only needs 40 seconds to achieve equalmixing.

2. Twin-spiral mixer enjoys high speed mixing capacity of high strength andhigh flowing concrete.

3. This product enjoys best workability in high-grade concrete mixing. It’s anupgraded product in new-type concrete mixers.

3) Highest cost performance

Owing to the excellent mixing efficiency of twin-spiral mixer, under thefeeding condition, concrete plant equipped with same mixer can add 50%production.

4) Self lubricate system

Self lubricate system adopts famous brand centralized system which is used inall engineering machinery. Reliable continuous oiling can ensure the longsealing of the shaft end.

5) High pressure cleaning equipment

High pressure cleaning equipment can help clean most adhering cement in themixer. Therefore, it largely reduces manual cleaning intensity,cleaning efficiency can achieve 95%.

Compared with double horizontal shaft mixer, the efficiencyof twin-spiral mixer increases 15%, saving 20% energy. Workability isthe best!

5. Technical parameters oftwin-spiral mixer

| Concrete property | Technical parameters | Mixing equipment | |

| Twin-spiral mixer | Common mixer | ||

| Common concrete | Mixing time(s) | 20 | 40 |

| Mixing cycle(s) | 45 | 72 | |

| Production capability(1m3☆☆) m3/h | 80 | 50 | |

| Production capability (1.5m3☆☆)m3/h | 120 | 75 | |

| Production capability (2m3☆☆) m3/h | 160 | 100 | |

| Production capability (3m3☆☆) m3/h | 240 | 150 | |

| Production capability (4m3☆☆) m3/h | 320 | 200 | |

| High performance concrete | Mixing time( s) | 40 | 120 |

| Mixing cycle(s) | 80 | 150 | |

| Production capability (1m3☆☆) m3/h | 45 | 24 | |

| Production capability (1.5m3☆☆) m3/h | 67.5 | 36 | |

| Production capability (2m3☆☆) m3/h | 90 | 48 | |

| Production capability (3m3☆☆) m3/h | 135 | 72 | |

| Production capability (4m3☆☆) m3/h | 180 | 96 | |

6. Double-horizontal-shaftmixer

High performance and high quality hexagonal shaft has the best torsionresistance and bending strength. Wear-resistant plate adopts rhomb reversibledesign to reduce the repairing cost. The special shaft bushing is more suitableto mix RCC concrete. High pressure rotary cleaning device: inner rotary headwith angle can ensure a good cleaning effect.

Main technical parameters

| Discharging capacity | 6000 |

| Feeding capacity | 9600 |

| Working cycle | ≤90 |

| Power | 4×55KW |

| Winding number of shaft | 16 |

| Max. diameter of aggregate | 100/180mm |

| Feeding fill factor | 0.4 |

| Diamond liner | 28mm |

| Mixing arm arrangement | 60°(120°) |

| Mixing shaft distance | 1490mm |

| Size(length × width ×height) | 5300×3600×2936 |

| Weight | ~23.5t |

1) Adopts pneumatic conveying device with small arrangementlimitation, compact structure, convenient use, low energy consumption, highautomatic strength, continuous operation and little environment pollution.

2) Air conveying chute features simple structure, light weight, fixedcomponents, good sealing, no noise and low energy consumption.

3) Seal type sand belt system is equipped with quality belt and safe protectiondevice to ensure the normal operation of the equipment.

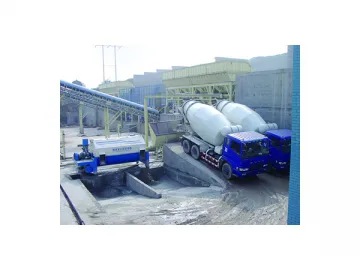

7. Wet concrete separatingand recycled reuse equipment

Profile chart of separating equipment

Good sealing can avoid the sewage from damaging; screen stencil and discharginghole are made of abrasive materials. Therefore, our products enjoy a long usinglife.

NGW speed reducer is used to protect from overload; when mixing, seriflux is boiling so that it can avoid precipitation.

Links:https://globefindpro.com/products/102388.html

-

Container Concrete Mixing Plant

Container Concrete Mixing Plant

-

Modular Concrete Mixing Plant

Modular Concrete Mixing Plant

-

Aluminum Sheet

Aluminum Sheet

-

Household Aluminium Foil

Household Aluminium Foil

-

Wet Concrete Cleaning and Separating Equipment(Concrete Recycling Equipment)

Wet Concrete Cleaning and Separating Equipment(Concrete Recycling Equipment)

-

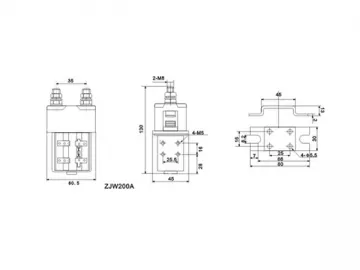

YF 200A DC contactor

YF 200A DC contactor

-

Skipped Concrete Mixing Plant

Skipped Concrete Mixing Plant

-

Aluminum Foil Wrap

Aluminum Foil Wrap

-

Aluminum Coil

Aluminum Coil

-

Dry Mortar Mixing Plant

Dry Mortar Mixing Plant

-

Asphalt and Cement Mortar Mixing Truck

Asphalt and Cement Mortar Mixing Truck

-

Screened Category 6 Cable

Screened Category 6 Cable