Container Concrete Mixing Plant

ContainerConcrete Mixing Plant

Convenient transportation, easy, fast installation and removal, suitable forconstruction site of frequent transitions. Savetime and places, bring large economical benefit for you!

Little dust, low noise, more environmental-friendly.

With the development of infrastructure constructions,construction enterprises need to remove frequently. However, traditional mixingplants are difficult to remove and expensive because of their structures. Basedon the above points, We developed container concretemixing plant which has achieved international advanced level.

Features

1.Standard transportation: thewhole plant can assemble five containers. Appearance design of every containercomplies to the international standard.

2.Fast installation and removal: containersare connected to each other through double-headed cone and bolt; socketconnection among functional systems.

3.Integrated design: each system module isseparately installed in 5 containers to achieve standard manufacturing.

4. User-friendly design and compactstructure: convenient to maintain and repair; reduce noise anddust pollution.

System distributions ofcontainer concrete mixing plant and features

1. Concretemixing

Doublespiral mixer

So the concrete mixing plant is suitable for mixingconcrete with wide range of mixture ratio. Workability is best when it is usedto mix high-grade concrete. This mixing plant enjoys 20% higher efficiency andsaves 15% energy more than common mixing plant.

Slumpmonitoring system

It is used to monitor mixing process in order tocontrol the concrete slump.

Telescopicdischarge hopper

Effectively prevent concrete spraying while loading and unloading.

Water pumpssystem

Rational design of waterway system, easy connection.

Apparatus cabinet

Embedded type; installed and tested in the factory.

2.Transitional system

Highpressure rotational cleaning device

Automatic rotary spray head can help clean most of the mortar, manual cleaningstrength is largely reduced. Cleaning efficiency: 95%

Gas circuitsystem

All components of the system are assembled in our factory; socket connection isadopted while they are carried to the work site.

3.Measurement system

Dust-collectingsystem

Impulse-type cloth bag is adopted to remove dusts, large area and efficient.

Water andadmixture weighing system

Powdermeasurement system

Special pneumostome is designed to achieve aconvenient use.

Gas circuitsystem

Embedded design, all components of the system are assembled in our factory.

4. Devicecontrol system and its features

(1) Advanced duplex computer is adopted inour concrete mixing plant.

(2) High performance hardware configuration ensures the stability andreliability; Industrial computer and main low voltage apparatus all adopt worldfamous brands.

(3) Good control function: full animation to imitate working condition.

(4) Simple operation and convenient maintenance: auto, semi-auto and manualoperating are all permissible; production data can beeasily preset.

Main technical parameters

| Technical performance | Technical performance | Technical parameters | ||

| Concrete mixer | HY2000 | Weighing scope | Aggregate(separate measurement) | 4×2400Kg±2% |

| Theoretical productivity | 120m3/h | Cement | 1200kg±1% | |

| Aggregate hopper capacity | 4×20m3 | Coal ash | 400Kg±1% | |

| Aggregate size | ≤80mm | Water | 500Kg±1% | |

| Weight of concrete mixer | Kg | Admixture | 2×30Kg±1% | |

| Discharging height | 3.8m | Size of concrete mixer | 6.1m×4.9m×11.6m | |

| Total capacity(exclude screw conveyor) | ≈140KW | Electric power | 380v/50Hz | |

Links:https://globefindpro.com/products/102393.html

-

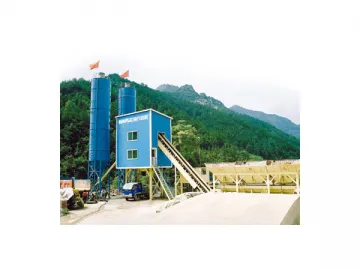

Modular Concrete Mixing Plant

Modular Concrete Mixing Plant

-

Aluminum Sheet

Aluminum Sheet

-

Household Aluminium Foil

Household Aluminium Foil

-

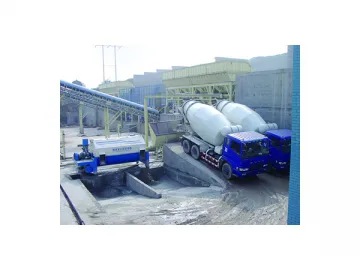

Wet Concrete Cleaning and Separating Equipment(Concrete Recycling Equipment)

Wet Concrete Cleaning and Separating Equipment(Concrete Recycling Equipment)

-

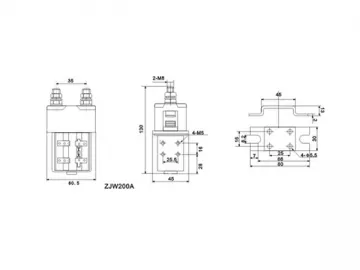

YF 200A DC contactor

YF 200A DC contactor

-

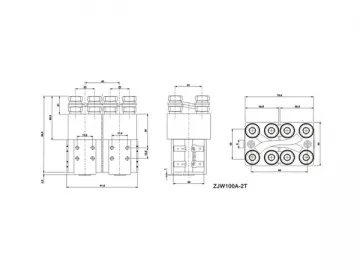

YF 100A-2T DC contactor

YF 100A-2T DC contactor

-

Ready-mixed Concrete Mixing Plant

Ready-mixed Concrete Mixing Plant

-

Skipped Concrete Mixing Plant

Skipped Concrete Mixing Plant

-

Aluminum Foil Wrap

Aluminum Foil Wrap

-

Aluminum Coil

Aluminum Coil

-

Dry Mortar Mixing Plant

Dry Mortar Mixing Plant

-

Asphalt and Cement Mortar Mixing Truck

Asphalt and Cement Mortar Mixing Truck