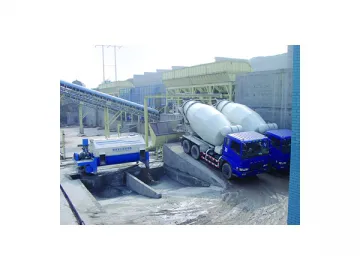

Wet Concrete Cleaning and Separating Equipment(Concrete Recycling Equipment)

Wet Concrete Cleaning andSeparating Equipment

(Concrete Recycling Equipment)

Descriptionsof Wet Concrete Cleaning and Separating Equipment

1. This is a kind of concrete recyclingequipment or separating machinery;

2. Main components: supporting wheels, sandstone discharging hole,concrete-washing-water discharging hole, screen device and alarming device etc..

3. The electrical motor, whose speed reducer is driven by triangle belt, isadopted to drive screen;

4. Screen system is supported by bearing and two carrier rollers: it canseparate sands and stones and wash them cleanly;

5. The screen and discharging hole is made ofwear-resistance material, so our concrete recycling equipment has a longerservice life.

6. The mixing device can effectively prevent precipitation ofconcrete-washing-water.

Applications of Wet ConcreteCleaning and Separating Equipment

Wet concrete cleaning and separating equipment is primarily used for cleaning,separating or recycling remained wet concrete.

The concrete recycling equipment can be widely used in concrete constructionfields.

Featuresof Wet Concrete Cleaning and Separating Equipment

1. Environmentally friendly: no polluted waterdischarging;

2. Cost saving: water saving and recycled wet concrete;

3. Separated gravels are clean and smooth as original;

4. Some components of the concrete recycling equipment can be processed andinstalled respectively: so our wet concrete cleaning and separating equipmentsare popular among concrete construction area especially among concrete batchingplant manufacturers.

Performanceof Wet Concrete Cleaning and Separating Equipment

1. Wet concrete cleaning and separating: 20-25 m3/h;

2. Wet mortar mixture processing: 30-35 m3/h;

3. Max. aggregate size: 45mm;

4. Min. aggregate size: 2mm;

Links:https://globefindpro.com/products/102399.html

-

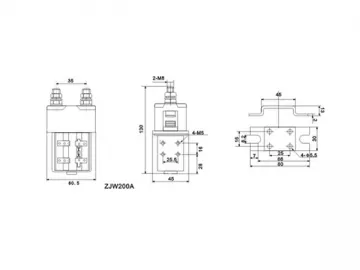

YF 200A DC contactor

YF 200A DC contactor

-

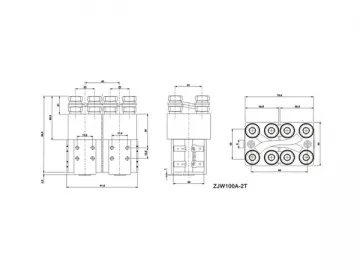

YF 100A-2T DC contactor

YF 100A-2T DC contactor

-

New-type HYCM Mobile Concrete Mixing Plant

New-type HYCM Mobile Concrete Mixing Plant

-

Fire Retardant Western Furniture

Fire Retardant Western Furniture

-

Special Concrete Mixing Plant for Express Railway

Special Concrete Mixing Plant for Express Railway

-

Soil Mixing Plant

Soil Mixing Plant

-

Household Aluminium Foil

Household Aluminium Foil

-

Aluminum Sheet

Aluminum Sheet

-

Modular Concrete Mixing Plant

Modular Concrete Mixing Plant

-

Container Concrete Mixing Plant

Container Concrete Mixing Plant

-

Ready-mixed Concrete Mixing Plant

Ready-mixed Concrete Mixing Plant

-

Skipped Concrete Mixing Plant

Skipped Concrete Mixing Plant