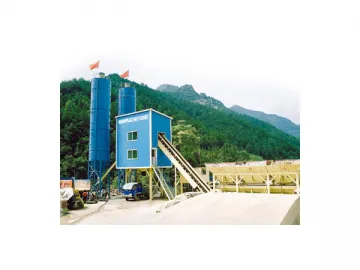

Modular Concrete Mixing Plant

Modular Concrete MixingPlant

HYCP modular concrete mixing plant is always used in concrete production orcivil engineering area, such as construction of airport, port, bridge, road andbuildings.

Good mixing performance

Double horizontal shaft forced concrete mixer is equipped, so our concretemixing plant features short mixing time, excellent mixing quality and it issuitable for mixing concrete of different mixture ratios.

Easy and convenient control

The whole plant is controlled by computer, auto-controlor manual control are both permissible. Dynamic panel displaying helps clearlyunderstand the operation conditions and save and print the production data.

Precise weighing system

No matter the weighing elements are aggregate, powder and water, or controlelement, they all adopt imported elements. Sampling speed can achieve 120times/second to ensure high quality and reliable performance.

Convenient maintenance

Maintenance platform and ladder is available, so it is convenient to repair ormaintain our concrete construction equipment.

Convenient transitioninstallation

Modular type: the proportioning machine, belt conveyor, concrete mixer, screwconveyor and powder tanks are all designed inindependentstructure. The concrete mixer consists of several independent modules. Thisplant is fast to take down and install in transition. Various types areavailable to meet customers’ different requirements.

Environmental friendly

All the powdery materials, from loading, proportion,weighing, feeding, mixing to discharging, are all carried on under sealedconditions. Mixing platform and sealed aggregate belt conveyor largely reducesdust and noise pollution.

Control system

Adopts industrial computer, I/O data collection and high precise weightingsystem, according to the technics and qualityrequirements of concrete manufacturing, software can control the machineoperating through control software, so the concrete mixing plant can collectproduction data and control the production process automatically.

The features of systemsoftware

1. Production continuity function to increaseproduction.

2. Automatic calculation of total batch quantity and single batch quantity soas to minimize operation errors.

3. Auto compensation and auto adjusting of production parameters to increasethe precision.

4. Auto calculation on water ratio.

HYCP Modular Concrete MixingPlant

| Main Technical Parameters | ||||||

| Model | HYCP50 | HYCP75 | HYCP100 | HYCP150 | HYCP200 | |

| Theoretical productivity | 50 | 75 | 100 | 150 | 200 | |

| Concrete Mixer | Model | Js1000 | Js1500 | Js2000 | Js3000 | Js4000 |

| Power(kW) | 2×22 | 2×30 | 2×37 | 2×55 | 2×75 | |

| Output(m3/batch) | 1 | 1.5 | 2 | 3 | 4 | |

| Aggregate size (mm) | ≤80 | ≤100 | ≤120 | ≤150 | ≤150 | |

| Aggregate hopper | Size (m3) | 3×13 | 3×13 | 3×13 | 4×20 | 4×20 |

| Quantity | 3 | 3 | 3 | 4 | 4 | |

| Belt conveying capacity (t/h) | 200 | 200 | 300 | 400 | 600 | |

| Weighing scope and precision | Aggregate (kg) | 2500±2% | 3500±2% | 4500±2% | 6500±2% | 9000±2% |

| Cement (kg) | 600±1% | 900±1% | 1200±1% | 1800±1% | 2400±1% | |

| Coal ash (kg) | 200±1% | 300±1% | 400±1% | 600±1% | 800±1% | |

| Water (kg) | 300±1% | 400±1% | 600±1% | 800±1% | 1000±1% | |

| Admixture (kg) | 10±1% | 30±1% | 30±1% | 50±1% | 50±1% | |

| Total Power (kW) | 82 | 108 | 127 | 178 | 220 | |

| Discharging height (m) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | |

Note

1. The power ofscrew conveyor is excluded from the total power;

2. The quantity and size of Aggregate hoppers are customizable;

3. The above parameters may change without notice.

Links:https://globefindpro.com/products/102394.html

-

Aluminum Sheet

Aluminum Sheet

-

Household Aluminium Foil

Household Aluminium Foil

-

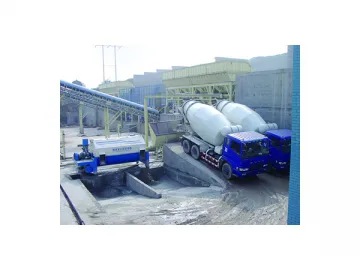

Wet Concrete Cleaning and Separating Equipment(Concrete Recycling Equipment)

Wet Concrete Cleaning and Separating Equipment(Concrete Recycling Equipment)

-

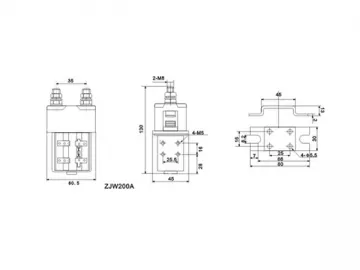

YF 200A DC contactor

YF 200A DC contactor

-

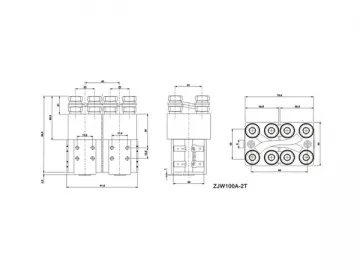

YF 100A-2T DC contactor

YF 100A-2T DC contactor

-

New-type HYCM Mobile Concrete Mixing Plant

New-type HYCM Mobile Concrete Mixing Plant

-

Container Concrete Mixing Plant

Container Concrete Mixing Plant

-

Ready-mixed Concrete Mixing Plant

Ready-mixed Concrete Mixing Plant

-

Skipped Concrete Mixing Plant

Skipped Concrete Mixing Plant

-

Aluminum Foil Wrap

Aluminum Foil Wrap

-

Aluminum Coil

Aluminum Coil

-

Dry Mortar Mixing Plant

Dry Mortar Mixing Plant