Welded Steel Pipe

Welded Steel Pipe

Our company invested ten million yuan RMB inDecember 2007 on the introduction of advanced international large steel pipeproduction line, specialized in the production of large diameter thick wallsubmerged arc welding straight seam steel tube, includingstraight isodiametric tubes, tapered tube and prismatic pipe,etc.

W&G INTERNATIONAL has four steel pipe production line,may according to the customer request for various specifications straight steelpipe manufacture. Our advanced equipments contain 2400 tons 1,600 tons of tubehydraulic press machine, hydraulic system, automatic tube preflexmachine, hydraulic essence of whole machine, automatic seaming machine, CNCautomatic cutting machine, numerical control large even pull automatic systemhole machine, ultrasonic inspection machine, automatic submerged arc weldingmachine, automatic CO2 protection welding machine, diameter expanding machine,hydraulic test machine and so on, all these are the current most advancedtechnology and equipments for steel pipe manufacturing. Our annual productioncapacity can reach 30,000 ton.

Feature

1. Simple process

2. High efficiency

3. Low cost

4. Rapid development

Application

Our weldedsteel pipe is suitable for paper machine pipe, high-rise steel structurepipe, machine roller pipe, liquid feeding pipe, bridge pipe, palestra pipe, piling pipe, thick coil pipe, rectanglepipe.

Specification

1. Diameter of longitudinal single seam welded pipe: 200mm-1000mm

2. Diameter of longitudinal multi (2-4) seam welded pipes: 800mm-4000mm

3. Pipe wall thickness: 6mm-60mm

4. Length of pipe without docking: 12mor per customer’s requirement

5. Material: Q195, Q215, Q235, Q275, Q295, Q345 or according to your requirements

6. Surface Coating: Hot dip galvanization or painting, anti-rust oil coating orblack painting

7. Standard: ISO9001:2008

8. Height: 5-85 M

9. Welding: CO2 welding or Submerged arc auto methods

10. Spare Parts: Parts for connection or installation will be provided

11. Lifetime: More than 25 years

12. Capacity: 40,000 MT per year

Joint details

1. Welded joint

It is the most widely used type for the joining of weldedsteel pipe. Steel pipe is relieved with beveled ends which are made withspecial equipment in compliance with the relevant standards.

2. Spherical socket joint

It provides the possibility of a rotation 10 degreesat the pipeline without the utilization of any special fittings. Steel pipesare welded from outside after proper erectioningaccording to required angle.

3. Spigot and socket joint

Especially used for the steel pipes inside coated withcement mortar. Steel pipes are welded from outside after erectioning.

4. Flanged joint

The special manufactured flanged are welded to theends of the pipe and then jointed with bolts.

Package

Standard Seaworthy packages

Design

Our welded steel pipe is designed according to your requirements.

After sale

It is executed in strict accordance with thecontents of the contract.

Project Experience

We have rich experience in making all kinds of transmission towers,communication towers, broadcasting towers, steel poles, substation structuresand all kinds of steel structures etc.

W&G INTERNATIONAL is a Chinawelded steel pipe manufacturer and supplier. We offer welded steel pipe, steelstructures, and communication tower. Our high quality products are offered atcompetitive prices. W&G INTERNATIONAL is located in China, and the full chain of manufacturingtransmission tower, steel poles can be completed in China, even in one city. Lowermanufacturing cost saves your purchasing cost. The more details of each productare shown on the page with description.

Links:https://globefindpro.com/products/108470.html

-

Solar Lighting Pole

Solar Lighting Pole

-

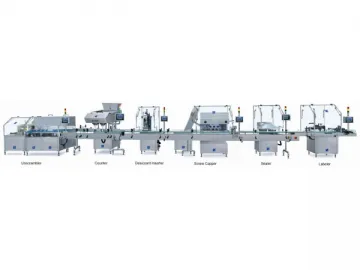

Electronic Tablet and Capsule Counting and Bottling Assembling Line

Electronic Tablet and Capsule Counting and Bottling Assembling Line

-

Substation Structure

Substation Structure

-

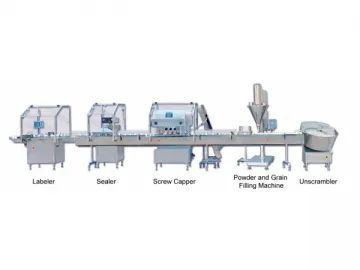

Powder and Grain Bottling Assembling Line

Powder and Grain Bottling Assembling Line

-

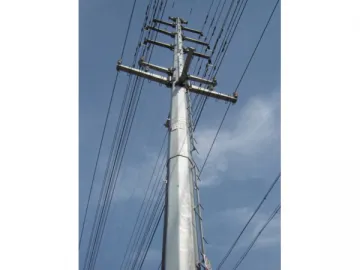

Single Tube Transmission Tower

Single Tube Transmission Tower

-

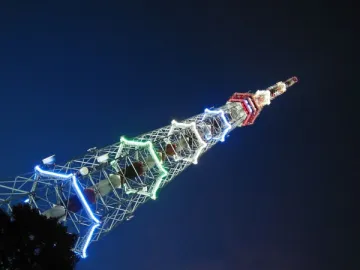

TV Tower

TV Tower

-

Wind Power Pole

Wind Power Pole

-

PL2000V Automatic Unscrambler

PL2000V Automatic Unscrambler

-

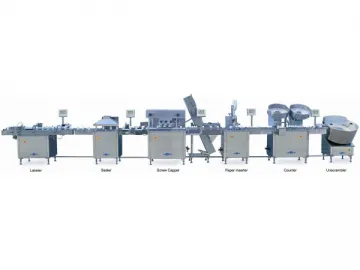

Template Type Tablet and Capsule Counting and Bottling Assembling Line

Template Type Tablet and Capsule Counting and Bottling Assembling Line

-

PL2000III Automatic Unscrambler

PL2000III Automatic Unscrambler

-

Steel Pole

Steel Pole

-

Angle Steel Tower

Angle Steel Tower