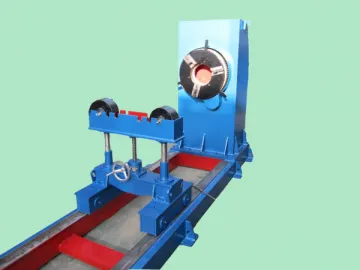

Rotary Welding Manipulator (Fixed Belt Column Boom Manipulator)

Rotary WeldingManipulator (Fixed Belt Column Boom Manipulator)

Features

The column and boom are manufactured with cold-formed welded type structure. After the annealing process and finish machining, they possess fine rigidity and strength. To ensure safety operation of the rotary welding manipulator, the boom lifting device uses a ratchet-and-pawl structure and is equipped with a fall protection device. Frequency control is applied for the adjustment of retracing speed, greatly improving the reliability and stability of the welding manipulator operation. The front end of the boom is manufactured with a cross adjustment structure which can be adjusted through the manual control box.

The eight guide wheels all utilize eccentric structure. During installation and set up, the lead rail tension can be adjusted by using the eccentric shaft. After this adjustment, the rail should be locked with double nuts.

The column rotation can be carried out with manual and electric control then locked. The electrical equipment includes a manual control box and electric cabinet.

The optional equipment of the rotary welding manipulator includes trolley, manned seat and worktable, drag chain, seam tracing and monitoring system, and flux recovering system.

Application

The welding manipulator, also called fixed beltcolumn boom manipulator, is used for the automatic welding of internal andexternal circular seams, and internal and external longitudinal seams of steamdrums and other cylindrical pieces in the boiler, pressure container, oil,machinery manufacturing industries and in the chemical industry.

Specifications

| Type | LHQ Light | LH Medium | LHM Heavy | LHW Super-Heavy | |

| Boom Lifting Stroke (mm) | 1-3 | 2-4 | 2-8 | 2-13 | |

| Boom Retracting Stroke (mm) | 1-3 | 1-4 | 2-8 | 4-12 | |

| Lifting Speed (mm/min) | 800 | 800 | 800 | 800 | |

| Retracting Speed (mm/min) | 120-1200 | 120-1200 | 120-1200 | 120-1200 | |

| Column Rotation | Angle(°) | ±180° | ±180° | ±180° | ±180° |

| Speed(rpm) | Manual | 0.11 Manual | 0.11 Manual | 0.10 Manual | |

| Trolley Travel Speed (mm/min) | Manual | 2000 | 2000 | 2000 | |

| Trolley Span (mm) | 1060 | 1500 | 2000 | 2500 | |

Materials

Column and boom: Edgefold welding structure with annealing process and finish machining

Lead rail: 45steel

Maintenance

To ensure a safe connection, the rotary welding manipulator should be grounded and reliably connected using the correct voltage. Should a problem arise, the power supply should be cut off immediately and the equipment inspected and repaired before operating the machine. Wiring located outside the equipment should be inspected for faculty connection. If a problem arises with the cable insulation, the equipment should be immediately stopped and overhauled. Welding should be performed in strict compliance with safety regulations and protective equipment must be worn while operating the rotary welding manipulator. The joint of the multicore cable should be inspected. If loose, it may cause poor contact and affect welding operation. To avoid breakage, the welding cable should not be twisted too often. Should a problem arise with the cable insulation, the machine must be immediately shut off and overhauled. The rotary welding manipulator should be operated in an area free from rainwater, corrosive gas and high temperature to avoid causing damage to electronic components or affecting operation functionality. A special power supply is required if frequent fluctuation of main voltage exists.

Packaginginformation

The following packaging is available

Palletizing plus plywood Wooden case Plastic film (nude packaging)

Services

HENGTONG rotary welding manipulator or fixed belt column boom manipulator comes with a one year warranty in which time we will solve any quality problems that should arise free of charge.

Our specialized after sales service personnel call and/or email our clients. We value our customers’ feedback which helps us improve our products.

We attend several international trade fairs each year and visit with clients in the city the trade show is located. We reply to our customers within 24 hours excluding holidays.

As a customer-oriented manufacturer of rotary welding manipulator in China, wealso produce many other types of equipment, including lifting type turningroll, L type welding positioner, and wind tower welding equipment, to name afew. In order to achieve customer satisfaction, we produce our products in linewith ISO9001:2000 international standard. If you have related need, please feelsecure in purchasing.

Links:https://globefindpro.com/products/110917.html

-

Steam / Electric Heating Vaporizer

Steam / Electric Heating Vaporizer

-

Head To Tail Welding Positioner

Head To Tail Welding Positioner

-

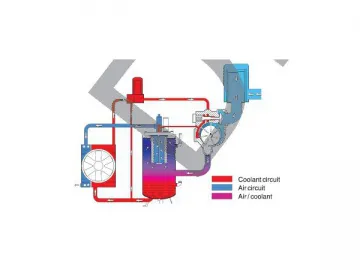

High Purity Nitrogen Plant

High Purity Nitrogen Plant

-

Cryogenic Liquid Storage Tank (Flat Bottom)

Cryogenic Liquid Storage Tank (Flat Bottom)

-

Air Compressor

Air Compressor

-

Energy Saving Lamp, Candle Shape CFL

Energy Saving Lamp, Candle Shape CFL

-

CNC Cutting Machine

CNC Cutting Machine

-

Dissolved Acetylene Equipment

Dissolved Acetylene Equipment

-

Piston Rod, Cylinder Rod

Piston Rod, Cylinder Rod

-

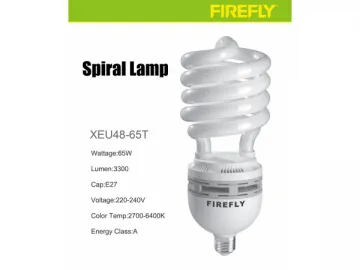

Energy Saving Lamp, Spiral Shape CFL

Energy Saving Lamp, Spiral Shape CFL

-

Rigid LED Light Bar

Rigid LED Light Bar

-

Conventional Turning Roll, Welding Rotator

Conventional Turning Roll, Welding Rotator