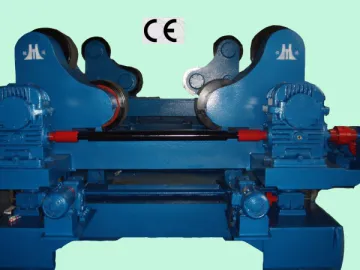

Conventional Turning Roll, Welding Rotator

Features

1. Composed of driving roller, return idler,electric cabinet and manually controlled box.

2. Distance between rollers can be adjusted tofit barrels with different diameters. Convenient to operate without the need of manual adjustment.

3. Frequency control is applied for theadjustment of roller speed, improving the reliability of equipment operation.

4. Easy to operate using manually controlledbox.

5. Can be designed for movable type, liftingtype, etc. with specially designed roller beds making welding more convenient.

6. Client can select materials for roller production. Materials include black rubber, polyurethaneand steel.

Application

Conventional turning roll is mainly used to weld the circular seam andlongitudinal seam of barrels, i.e., pressure containers, boilers, etc.

Specifications of ApplicableBarrels

Weight: 1-2000T

Diameter: Over 50mm

Shape: Cylindrical without projection

Specifications

|

Type | Max Loading Capacity (kg) | Applicable Workpiece Dia. (mm) | Roller Dia. and Width | Roller speed (m/h) | Motor Power | Roller Distance Adjust |

Speed Adjust | |

| Rubber roller | Metal roller | |||||||

| HGK-2 | 2000 | Φ150-2000 | Φ200×100 | / | 6-60 | 2 ×0.18 | Manual Lead Screw or Bolt Grading

|

Variable Frequency Drive (VFD)

|

| HGK-5 | 5000 | Φ250-2800 | Φ250*100 | Φ244×16*2 | 6-60 | 2 ×0.37 | ||

| HGK-10 | 10000 | Φ300-3200 | Φ300*120 | Φ294×25*2 | 6-60 | 2×0.55 | ||

| HGK-20 | 20000 | Φ500-4500 | Φ350*120 | Φ344×30*2 | 6-60 | 2×1.1 | ||

| HGK-40 | 40000 | Φ500-5000 | Φ400*120 | Φ394×50*2 | 6-60 | 2×1.5 | ||

| HGK-60 | 60000 | Φ500-5000 | Φ450*120 | Φ444×50*2 | 6-60 | 2×2.2 | ||

| HGK-80 | 80000 | Φ800-6000 | Φ500*120 | Φ494×60*2 | 6-60 | 2×3 | ||

| HGK-100 | 100000 | Φ800-6000 | Φ500×120 | Φ494×80*2 | 6-60 | 2×4 | ||

| HGK-200 | 200000 | Φ800-6500 | / | Φ700×250 | 6-60 | 2×4 | ||

| HGK300 | 300000 | Φ800-6500 | / | Φ800×300 | 6-60 | 2×5.5 | ||

| HGK-500 | 400000 | Φ1000-8000 | / | Φ800×350 | 6-60 | 2×7.5 | ||

| HGK-800 | 500000 | Φ1000-8000 | / | Φ900×400 | 6-60 | 2×11 | ||

Materials of Conventional Turning Roll, Welding Rotator

Steel plate: 16Mn

Roller: Black rubber, polyurethane andsteel

Maintenance

1. Theequipment should be cleared before using. Rubber rollers should be kept away from oils and heat to avoidaging. If possible, the equipment shouldassigned to one specific person for operation and maintenance.

2. Duringinstallation and start up, the speed reducer must befilled with 30# machine oil, this is also necessary when the environmentaltemperature is below 0℃. The oil should be completely replaced after the first month in use, thenchanged every six months.

3.

Links:https://globefindpro.com/products/110911.html

-

Rigid LED Light Bar

Rigid LED Light Bar

-

Energy Saving Lamp, Spiral Shape CFL

Energy Saving Lamp, Spiral Shape CFL

-

Piston Rod, Cylinder Rod

Piston Rod, Cylinder Rod

-

Dissolved Acetylene Equipment

Dissolved Acetylene Equipment

-

CNC Cutting Machine

CNC Cutting Machine

-

Rotary Welding Manipulator (Fixed Belt Column Boom Manipulator)

Rotary Welding Manipulator (Fixed Belt Column Boom Manipulator)

-

Lifting Type Welding Rotator, Turning Roll

Lifting Type Welding Rotator, Turning Roll

-

4D22F

4D22F

-

LED Flood Light

LED Flood Light

-

Custom Made Welding Rotator, Turning Roll

Custom Made Welding Rotator, Turning Roll

-

LED Panel Light

LED Panel Light

-

Custom Made Turning Roll, Welding Rotator

Custom Made Turning Roll, Welding Rotator