Surface Finishing Service

In addition to die casting tooling and machining, surface finishing is an essential procedure for optimizing appearance and performance, such as added corrosion resistance and wear.

For metal casting, there are some common processing methods like grinding, sandblasting, powder coating, plating and buffing. Here are some recommended surface finishing services in our company:

1. Sandblasting The die cast sandblasting takes advantage of steel microspheres propelled against the surface to make plastic deformation for enhancing the strength of the part.

2. Powder CoatingThe powder coating attaches organic powders to the surface through electrostatic attraction in order to achieve both decorative and protective purposes against corrosion. Compared with liquid coating, powder coating does not require a solvent with less environmental impact.

Recommended applications: the surface of external parts of vehicle, machine and electronic product

3. PlatingThe plating forms one or more metal coatings on the surface of base materials, for greater corrosion resistance, improved thermal stability, increased durability, and other superior performance. There are a wide range of plating methods, such as electroplating, electroless plating, composite plating, hot-dip galvanization and spray coating.

Recommended applications: the surface of internal parts of vehicle, machine and electromechanical equipment

Links:https://globefindpro.com/products/11462.html

-

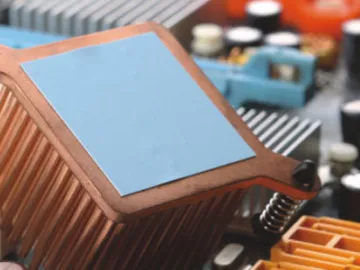

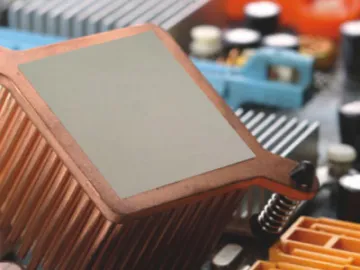

Thermal Conductive Pads, Gap Pads

Thermal Conductive Pads, Gap Pads

-

Design and Production of Die Cast Tooling

Design and Production of Die Cast Tooling

-

Cases

Cases

-

Die Casting for Auto Parts

Die Casting for Auto Parts

-

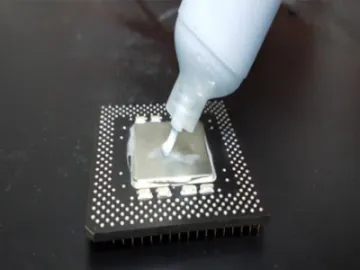

Thermal Interface Grease

Thermal Interface Grease

-

Low Density Thermal Interface Pad

Low Density Thermal Interface Pad

-

Nonwoven Manufacture

Nonwoven Manufacture

-

Professional Counselling

Professional Counselling

-

Thermal Conductive Putty

Thermal Conductive Putty

-

Die Casting for Auto Parts

Die Casting for Auto Parts

-

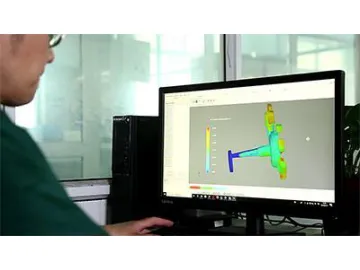

Automotive Electronics

Automotive Electronics

-

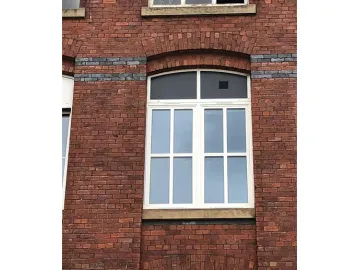

Swing Windows

Swing Windows