Design and Production of Die Cast Tooling

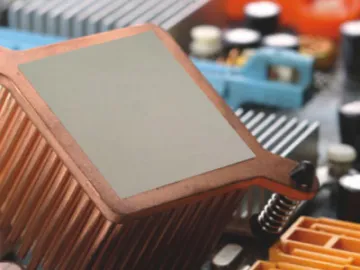

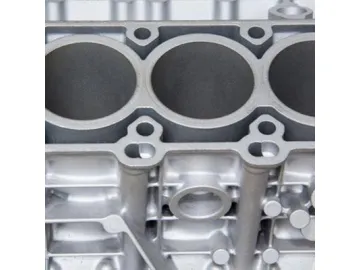

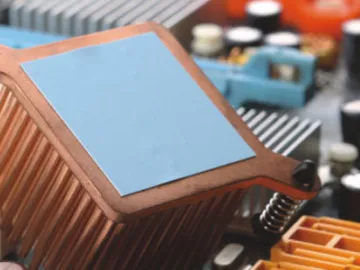

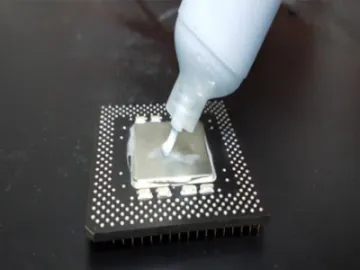

As a crucial element of the whole process, the die casting tooling plays a significant role in the deformation. Our die cast molds can achieve high accuracy and productivity, used over and over again. We use popular hardened tool steels in the market, such as SKD61 or H13, to ensure strong durability.

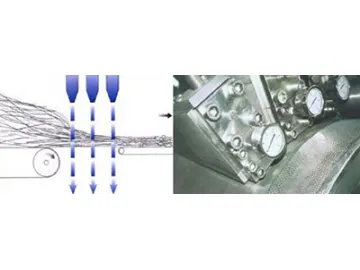

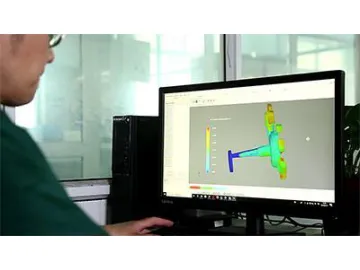

Experienced designers take advantage of Modeflow and FEMA(Failure Mode and Effect Analysis) for the preliminary design and validation of die cast molds. Take potential factors affecting the product quality into consideration and eliminate possible problems in advance.

Customized Die Cast MoldThere are two main die cast tooling processes available in our company: multi-slide die cast tooling and conventional die cast tooling.

The multi-slide tooling can achieve intricate shapes of die castings first time, perfectly avoiding secondary operations and reducing production cost.

The conventional tooling is designed with two slides and guarantee efficiency in production with lower cost. We can provide predictive wear analysis to ensure that the finished product is capable of bulk production.

High Quality Die Cast MoldDie cast molds are deformed by the molten metal under high pressure. In die casting, due to the direct and frequent contact with the molten metal when the mold temperature is high, there are some special properties required for mold materials:

Great hardenability, tenacity and wear resistance of tool steels at high temperatures

Excellent thermal shock resistance, avoiding early cracks

High thermal conductivity, inoxidizability and corrosion resistance

Links:https://globefindpro.com/products/11464.html