Extrusion Coating and Laminating Line for Flexible Packaging

Snack food bag, candy wrapper, medical barrier packaging, soup sachets, toothpaste tube, milk pouch, laminating film, lidding film, thermal film etc.

Technical Data Resins: PE, EVA, EAA, PP, etc.Substrate: BOPP film, BOPET film, BOPA film, aluminum foil, etc.

Extruder: 90mm, 110mm, customized

Net width: 1300mm, 1600mm, customized

Machine speed: 200m/min, 300m/min, customized

Unwinder: turret type with auto splicer Winder: turret type with auto splicer

Tension control: fully automatic constant tension

Thickness gauge: on-line measurement unit

Primer coater: optional

Finished roll dia.: 1000mm, customized

Line control: PLC & HMI

In extrusion coating and laminating, the resins, melted and formed into a hot thin film, is joined with the substrate materials like paper, PET film or aluminum foil. By such a converting process, we are able to deliver a high-performance packaging materials for a variety of applications.

Our extrusion coating machine for thermal film provide our customers with the best cost-efficient solution. Our machine is equipped with the most effective extruder design, turret winder & unwinder, automatic splicer, and control technology. For best adhesion with PET film and aluminum foil, primer coater and drying unit can be added to our extrusion coating machine, so one machine will have both liquid glue coating and dry extrusion coating.

Links:https://globefindpro.com/products/2732.html

-

Stretch Film Extrusion Line, Cast Stretch Film Machine

Stretch Film Extrusion Line, Cast Stretch Film Machine

-

Rotary Screw Air Compressor, 0.5 MPa, HNS/D Series

Rotary Screw Air Compressor, 0.5 MPa, HNS/D Series

-

Hot Melt Glue Laminating & Coating Machine

Hot Melt Glue Laminating & Coating Machine

-

PETG Shrink Film Extrusion Line

PETG Shrink Film Extrusion Line

-

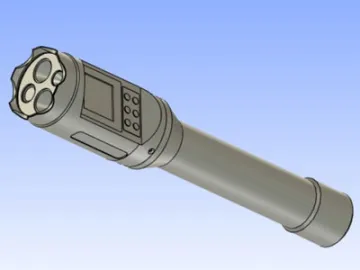

EVcam50-IR Flashlight DVR Camera

EVcam50-IR Flashlight DVR Camera

-

Specialty Film Extrusion Line

Specialty Film Extrusion Line

-

3-Layer CPP Film Line, CPP Film Machine

3-Layer CPP Film Line, CPP Film Machine

-

Monofilament Extrusion Line

Monofilament Extrusion Line

-

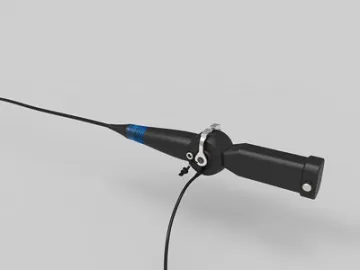

ECP Series Videoscope Probe

ECP Series Videoscope Probe

-

Barrier Cast Film Line

Barrier Cast Film Line

-

Extrusion Coating Lamination Line for Paper

Extrusion Coating Lamination Line for Paper

-

TPU Cast Film Line

TPU Cast Film Line