3-Layer CPP Film Line, CPP Film Machine

Film thickness range 0.02-0.15mm

Net film width From 1000mm to 4000mm

Film structure 1-layer, 3-layer, or 5-layer Applications

Wide packaging application for processed food and bakery products, cosmetics, pharmaceutical, bakery, confectionery, stationery, apparel, DVD case and flower; lamination grade CPP film used as a heat seal layer along with BOPP or polyester film in a laminate for packing the articles; metalized grade CPP film with co-polymer and homo-polymer to meet the specialized needs for the packaging of various products.

Line Layout Technical Parameters

| Model No. | FMC65/110/65-1600 | FMC65/125/65-2000 | FMC90/135/90-2500 |

| Screw Dia. | 65mm/110mm/65mm | 65mm/125mm/ 65mm | 90mm/135mm/ 90mm |

| Die Width | 2000mm | 2400mm | 2900mm |

| Film Width | 1600mm | 2000mm | 2500mm |

| Film Thickness | 0.02-0.150mm | 0.02-0.150mm | 0.02-0.150mm |

| Line Speed | 250m/min | 250m/min | 250m/min |

* Remarks: Machine dimensions can be customized upon request.

OverviewThe CPP cast film line is used to produce high-quality cast polypropylene film (CPP film) for a wide range of packaging applications. Equipped with auto thickness controlling system and efficient chill roll, the line produces CPP film of high transparency and very low gauge variation, ideal for laminating and metalizing. The 3-layer or 5-layer CPP film is most welcome in the market.

CPP (Cast Polypropylene Film) is a cost-effective, low density, high-performance transparent cast polypropylene film. CPP films are able to have optical clarity, high gloss, good seal strength, and machinability, and are resistant to tears and punctures. These product features make this polymer film good for the medical, food packaging, and textile industries.

FeaturesOptions for up to 5-layers coextruded film structure

Option for up to 4000mm film wide

Air knife and high performance chill roller

Automatic film thickness controlling

In-line edge trim and recycling

Links:https://globefindpro.com/products/2731.html

-

Extrusion Coating and Laminating Line for Flexible Packaging

Extrusion Coating and Laminating Line for Flexible Packaging

-

Stretch Film Extrusion Line, Cast Stretch Film Machine

Stretch Film Extrusion Line, Cast Stretch Film Machine

-

Rotary Screw Air Compressor, 0.5 MPa, HNS/D Series

Rotary Screw Air Compressor, 0.5 MPa, HNS/D Series

-

Hot Melt Glue Laminating & Coating Machine

Hot Melt Glue Laminating & Coating Machine

-

PETG Shrink Film Extrusion Line

PETG Shrink Film Extrusion Line

-

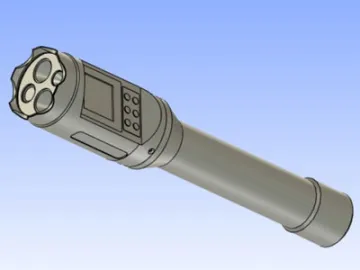

EVcam50-IR Flashlight DVR Camera

EVcam50-IR Flashlight DVR Camera

-

Monofilament Extrusion Line

Monofilament Extrusion Line

-

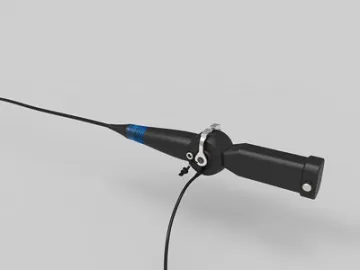

ECP Series Videoscope Probe

ECP Series Videoscope Probe

-

Barrier Cast Film Line

Barrier Cast Film Line

-

Extrusion Coating Lamination Line for Paper

Extrusion Coating Lamination Line for Paper

-

TPU Cast Film Line

TPU Cast Film Line

-

Rotary Screw Air Compressor, HNS-50A Series

Rotary Screw Air Compressor, HNS-50A Series