Fiber Glass Epoxy Sheet and Rod

We utilize electrical glass cloth impregnated with epoxy resin under heat and pressure to manufacture our fiber glass epoxy sheet and rod. This kind of reinforced thermoset is born with extraordinary mechanical strength and dielectric properties.

This plastic material is applicable for insulating parts used in electric motors and electronic appliances. Moreover, our fiber glass epoxy product is also capable of handling humid condition and insulating oil.

Strength

1. Oil resistant

2. Outstanding inertness to all kinds of solvents and acid chemicals

Application

1. Parts for chemical equipment and general machinery

2. Base plate, support and guard panel for electric generator

3. Insulating parts for transformer, inverter, electric motor, distribution box, fixture board material, clamp plate for molds, high and low voltage wiring closet, as well as packaging machine

4. Mechanical mold, fixture material for PCB (printed circuit board) and ICT (in-circuit test), as well as forming machine, drilling machine and base plate for grinding, etc.

Type

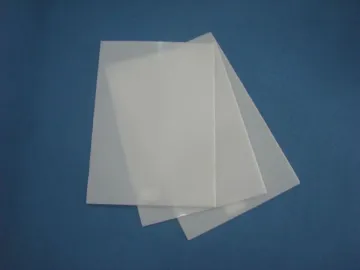

1. 3240 fiber glass epoxy sheet

Our fiber glass epoxy sheet is offered in yellow color.

Dimension

| Fiber glass epoxy sheet | |

| Thickness (mm) | Width × length (mm) |

| 0.5 to 1.5 | 1020 × 2020 |

| 2 to 2.5 | 1020 × 2020 |

| 3 to 50 | 1020 × 2020 |

| 60 to 100 | 1020 × 2020 |

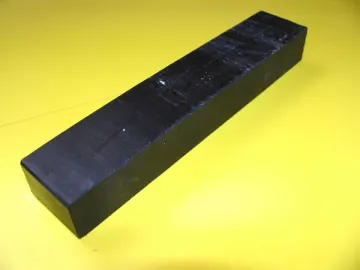

2. 3640 fiber glass epoxy rod

We supply this product also in yellow color.

Dimension

| Fiber glass epoxy rod | |

| Diameter (mm) | Length (mm) |

| 20 to 60 | 1000 |

| 65 to 150 | 1000 |

| 150 to 200 | 500, 1000 |

Technological requirement

The surface is smooth and free from bubble, corrugate and crack.

Technological data sheet

| No. | Item | Unit | Value | Note |

| 1 | Vertical bending strength | MPa | ≥340 | - |

| 2 | Parallel impact resistance (Charpy) | kj/m2 | ≥33 | Meeting either one is enough. |

| 3 | Parallel Izod impact resistance | kj/m2 | ≥34 | |

| 4 | Vertical electrical strength at 90°C ± 2°C in oil | MV/m | See No. 5 | - |

| 5 | Parallel breakdown voltage at 90°C ± 2°C in oil | kV | ≥35 | - |

| 6 | Relative dielectric constant (from 48Hz to 62Hz) | - | ≤5.5 | Meeting either one is enough. |

| 7 | Relative dielectric constant (below 1MHz) | - | ≤5.5 | |

| 8 | Vertical temperature resistance | °C | ≥200 | |

| 9 | Thermal stability | °C | 200 | |

| 10 | Oil resistance (in insulating oil for 4 hours) | °C | 130 | |

| 11 | Tensile strength (vertical)(parallel) | MPa | ≥314≥216 | |

| 12 | Bonding strength | N | ≥5600 | |

| 13 | Surface resistivity (normal)(immersion in water) | MΩ | ≥1 ×≥1 × | |

| 14 | Volume resistivity (normal)(immersion in water) | MΩ | ≥1 ×≥1 × | |

| 15 | Parallel insulation resistance (normal)(immersion in water) | MΩ | ≥1 ×≥1 × | |

| 16 | Dielectric dissipation factor (from 48Hz to 62Hz) | - | ≤0.04 | Meeting either one is enough. |

| 17 | Dielectric dissipation factor (below 1MHz) | - | ≤0.04 | |

| 18 | Insulation resistance after immersion in water | Ω | ≥5.0 × | - |

| 19 | Density | g/cm3 | 1.7 to 1.9 | - |

Links:https://globefindpro.com/products/44428.html