Mash System

This mash system is primarily composed of mash tun, lauter tun, brew kettle, whirlpool kettle, hop dosing device etc.

All the system is made from high quality stainless steel 304 on par with the international standard. Moreover, we take advantage of multiple modernized manufacturing technologies, such us the automatic plasma, laser cutting, and pure argon gas-shielded welding, among others.

The inner part of our machines in touch with mash or other materials has gone through the mirror polishing process, and the outer part receives a Matt finish. In this way, we can provide our clients with a mash system featuring high technology, superior quality, low price, and beautiful appearance. The working volume ranges from 300L to 10,000L.

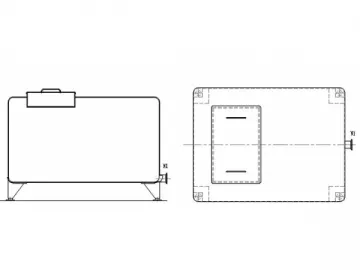

Mash Tun

1. We adopt the high-efficiency heat transfer technology of the honeycomb-shaped panel jacket, and also apply the scientific principle of the steam flow, so as to maximize the effects of both heat conduction and energy saving. Meanwhile, we utilize the full-automated temperature control technology to guarantee the accuracy of both heating rate and soaking time in all stages of the saccharification and gelatinization processes.

2. Furthermore, we make use of the advanced suspension type speed control system, as well as the frequency conversion and self-controlled stirring methods. In this way, the liquid wort can be uniformly mixed during the gelatinization and saccharification processes. Also, the optimal biological activity, transformation and catalytic effects of various enzymes can be maximized in these two processes. Then, the highest product yield and the best quality of beer can be guaranteed from the source.

Lauter Tun

1. By adoption of the advanced irregular-shaped rake system and the automatically-lifting hydraulic technology, the wort can be evenly distributed and stably drawn out of the tun. Additionally, the filtration rate and production efficiency are increased, and the high yield and favorable transparency of wort can be maintained within the mash system.

2. Moreover, we choose the sophisticated suspension and agitation equipment, accompanied with the frequency conversion, speed regulation, and automatic control technology. This enables the lauter tun to offer such advantages as flexible operation, easy maintenance, and significant cost reduction.

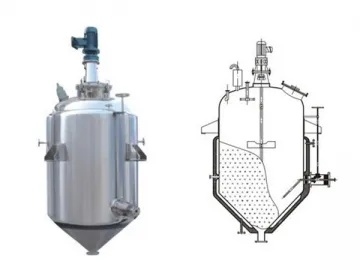

Boiler

1. The adoption of the internally boiling and pressure boosting technology can not only enhance the boiling intensity and greatly improve the evaporation effect of dimethyl sulphide, but also facilitate the polymerization of proteins or some others, and fast separate the boiling wort from polymers.

2. The use of externally circulating and mixing technique can accelerate the heating rate in the initial stage of boiling the wort. Then, the wort can always maintain a uniform temperature when being heated, so as to avoid the denaturation of wort soluble substances resulted from local overheating. Consequently, the quality of wort boiling can be guaranteed within the mash system.

Settling Tank

1. The settling tank of our mash system is designed on basis of the best accumulated amount of spent grains per filtration area. It enlarges the height-diameter ratio of the tank body, and also lowers the settling speed. In addition, it encourages the sedimentation and condensation of coagulum, and also realizes the optimal separation.

2. Coordinated with the thermal coagulation tank, this settling tank can increase the wort yield and also reduce the environmental pollution.

Hop Dosing device

1. The hop dosing platform of our mash system can consist of two or more tanks. Configured with pump, pipeline, valve and other accessories, it can realize that the dosage is automatically controlled.

2. The tank, valve, pipeline and other accessories in this hop dosing platform can be connected to the CIP system, which can achieve the automatic or semi-automatic cleaning and disinfection.

Related Names

Beer Making Kit | Distillery Equipment | Recirculating Mash Tun

Links:https://globefindpro.com/products/45934.html

-

Multifunctional Herbal Extraction Plant

Multifunctional Herbal Extraction Plant

-

Milk Silo

Milk Silo

-

Glycol Chiller

Glycol Chiller

-

Milk Receiver Tank

Milk Receiver Tank

-

Alcohol Deposition Tank

Alcohol Deposition Tank

-

Alcohol Recovery Tower

Alcohol Recovery Tower

-

Double Effect Vacuum Evaporator

Double Effect Vacuum Evaporator

-

Plate Heat Exchanger

Plate Heat Exchanger

-

Malt Mill

Malt Mill

-

Single Effect Vacuum Evaporator

Single Effect Vacuum Evaporator

-

Stainless Steel Swageless Terminal

Stainless Steel Swageless Terminal

-

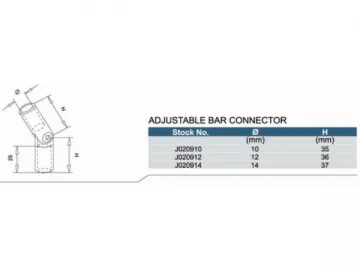

Stainless Steel Adjustable Upright Tube-Bar Connector

Stainless Steel Adjustable Upright Tube-Bar Connector