Glycol Chiller

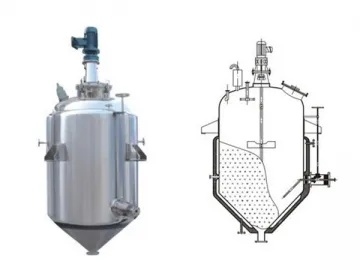

Our glycol chiller consists of the cold liquor tank, refrigeration unit, evaporator, pipeline valve, and the control system. Among them, the refrigeration unit serves as the core part. Our compressor unit generally adopts liquid ammonia as the refrigerant, and the temperature of beer can be directly lowered within the fermentation tank or brite tank.

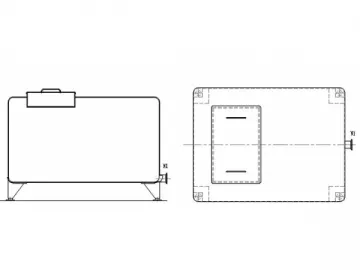

1. Structure of Cold Liquor Tank

This double-layered tank in our glycol chiller is filled with thermal insulation materials on basis of the requirements of our users. Its inner part receives a polished finish, and the roughness average reaches up to 0.4μm. In addition, its outer part is designed with the mirror board or Matt board for thermal insulation. There are different capacities for option, which range from 500L to 300,000L. Also, our product can be designed and manufactured according to the actual needs of our customers.

Structural Features

a. The upper bottom of our tank is conical, and the lower bottom is sloped.

b. The main body of this tank is a quite high cylinder.

2. Jacket Structure

This glycol chiller makes use of the coil-pipe jacket inside the tank, which is installed in compliance with the heat transfer area and technical requirements. In addition, the refrigeration unit is utilized for chilling.

3. Washing System

The CIP cleaning ball is mounted on top of the tank.

4. Accessories

In addition, the top of our cold liquor tank is assembled with the manhole, water inlet, reflux inlet, overflow outlet, and CIP inlet. It can be configured with air respirator based on the technical needs. Moreover, our glycol chiller is fitted with the thermometer and the liquid level gauge. All accessories are connected by tri-clamp.

Related Names

Beer Cooling Machine | Wort Cooler | Brewery Refrigeration Equipment

Links:https://globefindpro.com/products/45938.html