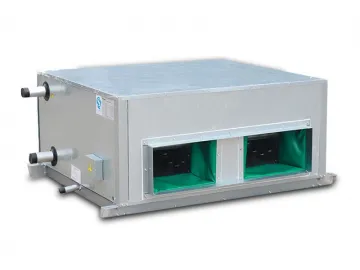

Ceiling Type Air Handling Unit

Ceiling mounted air cooling units are used for ventilation and refrigeration in a number of buildings, ranging from industrial factories to shopping malls.

| Model RFPD/4H | Air Flow (m³/h) | Rated cooling cap. (KW) | Rated heating cap. (KW) | Water Flow (m³/h) | Water D.P. (kpa) | ESP (pa) | Motor power (KW) | Dimension | Weight (KG) | Noise dB(A) | Water pipe (DN) | Drain pipe (DN) | ||

| L | W | H | ||||||||||||

| 010 | 1000 | 5.1 | 10.2 | 0.88 | 4.2 | 60 | 0.25 | 850 | 600 | 520 | 56 | 57 | 32 | 25 |

| 015 | 1500 | 8.4 | 15.2 | 1.44 | 9 | 60 | 0.25 | 950 | 650 | 570 | 63 | 57 | 40 | 25 |

| 020 | 2000 | 11.7 | 21.4 | 2.01 | 10.8 | 60 | 0.25 | 1100 | 750 | 570 | 81 | 58 | 40 | 25 |

| 025 | 2500 | 14.7 | 25.4 | 2.53 | 17.6 | 90 | 0.37 | 1100 | 850 | 570 | 83 | 59 | 40 | 25 |

| 030 | 3000 | 17.9 | 31.5 | 3.08 | 32 | 150 | 0.55 | 1100 | 1000 | 570 | 102 | 60 | 40 | 25 |

| 040 | 4000 | 23.6 | 41.1 | 4.06 | 60 | 180 | 0.75 | 1100 | 1280 | 620 | 106 | 60 | 40 | 25 |

| 050 | 5000 | 28.6 | 51.3 | 4.92 | 40 | 200 | 0.45x2 | 1100 | 1500 | 620 | 132 | 61 | 40 | 25 |

| 060 | 6000 | 35 | 62 | 6.02 | 42 | 200 | 0.55X2 | 1100 | 1630 | 620 | 152 | 62 | 50 | 25 |

| 070 | 7000 | 41 | 71 | 7.05 | 56 | 250 | 0.75x2 | 1100 | 1730 | 680 | 210 | 63 | 50 | 25 |

| 080 | 8000 | 45.5 | 84.3 | 7.83 | 32 | 250 | 0.75X2 | 1100 | 1730 | 740 | 251 | 63 | 50 | 25 |

| 090 | 9000 | 53 | 92.5 | 9.12 | 36 | 250 | 0.75x2 | 1100 | 1830 | 740 | 282 | 65 | 50 | 25 |

| 105 | 10500 | 62.1 | 110 | 10.68 | 48 | 280 | 1.1x2 | 1200 | 2130 | 740 | 302 | 67 | 50 | 25 |

| 120 | 12000 | 71 | 133 | 12.21 | 62 | 280 | 1.1x2 | 1200 | 2130 | 840 | 307 | 67 | 50 | 25 |

| 135 | 13500 | 77 | 148 | 13.24 | 25.4 | 320 | 1.8x2 | 1200 | 2130 | 900 | 375 | 69 | 65 | 25 |

| 150 | 15000 | 86.5 | 153.5 | 14.88 | 26.4 | 320 | 2.2x2 | 1200 | 2130 | 970 | 386 | 70 | 65 | 25 |

| NOTE: 1. Cooling conditions: inlet air DB27°C,WB19.5°C, inlet water temperature 7°C/12°C.2. Heating conditions: inlet air DB21°C, inlet water temperature 60°C/50°C. | ||||||||||||||

| Model RFPD/6H | Air Flow (m³/h) | Rated cooling cap. (KW) | Rated heating cap. (KW) | Water Flow (m³/h) | Water D.P. (kpa) | ESP (pa) | Motor power (KW) | Dimension | Weight (KG) | Noise dB(A) | Water pipe (DN) | Drain pipe (DN) | ||

| L | W | H | ||||||||||||

| 010 | 1000 | 7.5 | 12.9 | 1.29 | 9 | 60 | 0.25 | 850 | 600 | 520 | 56 | 57 | 32 | 25 |

| 015 | 1500 | 113 | 20.6 | 1.94 | 18.6 | 60 | 0.25 | 950 | 650 | 570 | 63 | 57 | 40 | 25 |

| 020 | 2000 | 15.1 | 26.7 | 2.6 | 26.3 | 60 | 0.25 | 1100 | 750 | 570 | 81 | 58 | 40 | 25 |

| 025 | 2500 | 18.6 | 31.6 | 3.2 | 37.6 | 90 | 0.37 | 1100 | 850 | 570 | 83 | 59 | 40 | 25 |

| 030 | 3000 | 22.3 | 38.5 | 3.84 | 25 | 150 | 0.55 | 1100 | 1000 | 570 | 102 | 60 | 40 | 25 |

| 040 | 4000 | 31.1 | 50.2 | 5.35 | 49.1 | 180 | 0.75 | 1100 | 1280 | 620 | 106 | 60 | 50 | 25 |

| 050 | 5000 | 36.2 | 62.3 | 6.23 | 32.6 | 200 | 0.55x2 | 1100 | 1500 | 620 | 132 | 61 | 50 | 25 |

| 060 | 6000 | 44.6 | 74 | 7.67 | 45.1 | 200 | 0.55x2 | 1100 | 1630 | 620 | 152 | 62 | 50 | 25 |

| 070 | 7000 | 50.4 | 85 | 8.67 | 60.3 | 250 | 0.75x2 | 1100 | 1730 | 680 | 210 | 63 | 50 | 25 |

| 080 | 8000 | 58.9 | 99.2 | 10.13 | 55.6 | 250 | 0.75x2 | 1100 | 1730 | 740 | 251 | 63 | 50 | 25 |

| 090 | 9000 | 65.3 | 112.6 | 11.23 | 24.5 | 250 | 1.1x2 | 1100 | 1830 | 740 | 282 | 65 | 50 | 25 |

| 105 | 10500 | 75.8 | 137.1 | 13.04 | 22 | 280 | 1.1X2 | 1200 | 2130 | 740 | 302 | 67 | 65 | 25 |

| 120 | 12000 | 86.8 | 162 | 14.93 | 24 | 280 | 1.5x2 | 1200 | 2130 | 840 | 307 | 67 | 65 | 25 |

| 135 | 13500 | 103.4 | 175.8 | 17.78 | 60 | 320 | 2.2x2 | 1200 | 2130 | 900 | 375 | 69 | 65 | 25 |

| 150 | 15000 | 109.1 | 186.2 | 18.77 | 62 | 320 | 2.2x2 | 1200 | 2130 | 970 | 386 | 70 | 65 | 25 |

| NOTE: 1. Cooling conditions: inlet air DB27°C,WB19.5°C, inlet water temperature 7°C/12°C.2. Heating conditions: inlet air DB21°C, inlet water temperature 60°C/50°C. | ||||||||||||||

| Model RFPD/6H | Air Flow (m³/h) | Rated cooling cap. (KW) | Rated heating cap. (KW) | Water Flow (m³/h) | Water D.P. (kpa) | ESP (pa) | Motor power (KW) | Dimension | Weight (KG) | Noise dB(A) | Water pipe (DN) | Drain pipe (DN) | ||

| L | W | H | ||||||||||||

| 010 | 1000 | 7.5 | 12.9 | 1.29 | 9 | 60 | 0.25 | 850 | 600 | 520 | 56 | 57 | 32 | 25 |

| 015 | 1500 | 113 | 20.6 | 1.94 | 18.6 | 60 | 0.25 | 950 | 650 | 570 | 63 | 57 | 40 | 25 |

| 020 | 2000 | 15.1 | 26.7 | 2.6 | 26.3 | 60 | 0.25 | 1100 | 750 | 570 | 81 | 58 | 40 | 25 |

| 025 | 2500 | 18.6 | 31.6 | 3.2 | 37.6 | 90 | 0.37 | 1100 | 850 | 570 | 83 | 59 | 40 | 25 |

| 030 | 3000 | 22.3 | 38.5 | 3.84 | 25 | 150 | 0.55 | 1100 | 1000 | 570 | 102 | 60 | 40 | 25 |

| 040 | 4000 | 31.1 | 50.2 | 5.35 | 49.1 | 180 | 0.75 | 1100 | 1280 | 620 | 106 | 60 | 50 | 25 |

| 050 | 5000 | 36.2 | 62.3 | 6.23 | 32.6 | 200 | 0.55x2 | 1100 | 1500 | 620 | 132 | 61 | 50 | 25 |

| 060 | 6000 | 44.6 | 74 | 7.67 | 45.1 | 200 | 0.55x2 | 1100 | 1630 | 620 | 152 | 62 | 50 | 25 |

| 070 | 7000 | 50.4 | 85 | 8.67 | 60.3 | 250 | 0.75x2 | 1100 | 1730 | 680 | 210 | 63 | 50 | 25 |

| 080 | 8000 | 58.9 | 99.2 | 10.13 | 55.6 | 250 | 0.75x2 | 1100 | 1730 | 740 | 251 | 63 | 50 | 25 |

| 090 | 9000 | 65.3 | 112.6 | 11.23 | 24.5 | 250 | 1.1x2 | 1100 | 1830 | 740 | 282 | 65 | 50 | 25 |

| 105 | 10500 | 75.8 | 137.1 | 13.04 | 22 | 280 | 1.1X2 | 1200 | 2130 | 740 | 302 | 67 | 65 | 25 |

| 120 | 12000 | 86.8 | 162 | 14.93 | 24 | 280 | 1.5x2 | 1200 | 2130 | 840 | 307 | 67 | 65 | 25 |

| 135 | 13500 | 103.4 | 175.8 | 17.78 | 60 | 320 | 2.2x2 | 1200 | 2130 | 900 | 375 | 69 | 65 | 25 |

| 150 | 15000 | 109.1 | 186.2 | 18.77 | 62 | 320 | 2.2x2 | 1200 | 2130 | 970 | 386 | 70 | 65 | 25 |

| NOTE: 1. Cooling conditions: inlet air DB27°C,WB19.5°C, inlet water temperature 7°C/12°C.2. Heating conditions: inlet air DB21°C, inlet water temperature 60°C/50°C. | ||||||||||||||

Notes

Fresh air working conditions: The air inflow dry bulb temperature is 7℃. Hot water inflow temperature is 60℃.Return air dry bulb temperature is 15℃. Hot water inflow temperature is 60℃. Features Use of an aluminum alloy frame ensures a light weight, making it convenient for onsite dismounting and maintenance.

Internal and external double layer polyurethane color steel panels avoids the formation of a cold bridge on the shell while operating.

Units are operated and tested using dynamic and static equilibrium tests before delivery.

Closed rolling bearings are used for the automatic adjusting center of gravity, automatic locking and push resistance. Pre-filling the lube oil ensures maintenance is not necessary during normal operating conditions.

The filter is a plate type that can be cleaned and reused.

Scan QR to Read

Links:https://globefindpro.com/products/48720.html

Links:https://globefindpro.com/products/48720.html

Recommended Products

-

Mushroom Planting Air Conditioner, 30kW-85kW Air Conditioner

Mushroom Planting Air Conditioner, 30kW-85kW Air Conditioner

-

Closed Loop Water Source Heat Pump, 2.6kW-40kW

Closed Loop Water Source Heat Pump, 2.6kW-40kW

-

Dog Kennel

Dog Kennel

-

Cassette Fan Coil Unit

Cassette Fan Coil Unit

-

Horizontal Type Air Handling Unit

Horizontal Type Air Handling Unit

-

Vertical Type Air Handling Unit

Vertical Type Air Handling Unit

-

Water Cooled Scroll Chiller and Heat Pump, 70kW-280kW

Water Cooled Scroll Chiller and Heat Pump, 70kW-280kW

-

Smoke and Heat Exhaust Fan

Smoke and Heat Exhaust Fan

-

Cold Room Axial Flow Fan

Cold Room Axial Flow Fan

-

VRV Air Conditioner, 25.2kW-200kW Variable Refrigerant Volume Air Conditioner

VRV Air Conditioner, 25.2kW-200kW Variable Refrigerant Volume Air Conditioner

-

Fabric Barn

Fabric Barn

-

Livestock Housing

Livestock Housing

Hot Products