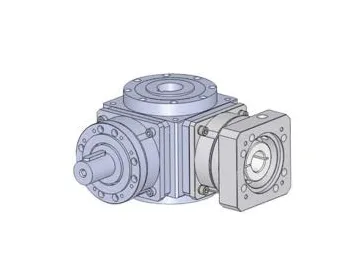

SWL Worm Gear Screw Jack

The SWL screw lift is a basic lifting device, capable of carrying out multiple functions, including raising, lowering, and pushing using auxiliary parts, pushing, turn over and height adjustments. These worm gear screw lifts are most often used for low speed, low frequency operations. Main components include precise trapezoid screw pairs and highly precise worm gear pairs.

When the screw lift is exposed to larger vibration amounts and impact loads, the self-locking mechanism will eventually no longer work correctly. To prevent this from happening, please add the brake unit.

Applications

· Platform lifting

· Working height adjustment for surface processing machines

· Tilt level adjustment for sliding transmission belts

· Working height modifications for correctors

· Automatic opening and closing for large scale/industrial windows and doors

Technical Parameters

| SWL Worm Screw Lift Parameters | ||||||||||

| Model | SWL1 | SWL2.5 | SWL5 | SWL10 | SWL15 | SW20 | SW25 | SW35 | SW50 | |

| Max. Lift Force (KN) | 10 | 25 | 50 | 100 | 150 | 200 | 250 | 350 | 500 | |

| Screw Rod Thread Size | Tr22x4 | Tr30x6 | Tr40x7 | Tr58x12 | Tr65x12 | Tr90x16 | Tr100x20 | Tr120x20 | ||

| Max. Tensile Force (KN) | 10 | 25 | 50 | 99 | 166 | 250 | 350 | 500 | ||

| Worm Gear ratio | P | 1/6 | 1/6 | 1/8 | 3/32 | 1/8 | 3/32 | 3/32 | 1/11 | |

| M | 1/24 | 1/24 | 1/24 | 1/24 | 1/24 | 1/32 | 1/32 | 1/32 | ||

| Screw Rod Stroke/R (mm) | P | 0.8 | 1 | 0.875 | 1.565 | 1.56 | 1.5 | 1.875 | 1.818 | |

| M | 0.21 | 0.25 | 0.292 | 0.5 | 0.5 | 0.5 | 0.625 | 0.625 | ||

| Max. elogation of screw rod under tension load (mm) | 1300 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 5500 | ||

| Max. Lift height under max. pressure load (mm) | Screw head with guiding | 220 | 250 | 385 | 500 | 400 | 490 | 850 | 820 | 900 |

| Screw head without guiding | 300 | 400 | 770 | 1000 | 800 | 980 | 1700 | 1640 | 1900 | |

| Worm torque with full load (N.m) | P | 15 | 18 | 39.5 | 119 | 179 | 240 | 3660 | 464 | 650 |

| M | 8.3 | 8.86 | 19.8 | 60 | 90 | 122 | 217 | 253 | 350 | |

| Efficiency (%) | P | 20 | 22 | 23 | 20.5 | 19.5 | 16 | 18 | 20 | |

| M | 9 | 11 | 11.5 | 13 | 12.8 | 9 | 11 | 15 | ||

| Power (KW) | 0.25 | 0.55 | 1.5 | 2.6 | 3.7 | 4.8 | 6 | 7.5 | ||

| Weight without stroke (Kg) | 6.3 | 7.3 | 16.2 | 25 | 36 | 70.5 | 87 | 95 | ||

| Screw weight per 100mm (Kg) | 0.35 | 0.45 | 0.82 | 1.67 | 2.15 | 4.15 | 5.2 | 6.35 | ||

| Lubricant | Synthetic Calcium-sodium base grease ZGN-1 or ZGN-2 (-20℃~+100℃) | |||||||||

| Grease Weight (Kg) | 0.08 | 0.1 | 0.3 | 0.5 | 0.75 | 1.1 | 1.9 | 2.2 | ||

Features

1. Compact structure, small volume, light weight

2. Extensive power source, no noise, convenient installation

3. Low speed, low frequency: The screw lift is primarily used in heavy load, slow speed and infrequent operation environments.

4. Continuous loading: The trapezoid screw rod features a self-locking function, allowing the machine to continuously load with no need for a brake.

5. Flexible applications, multiple functions, multiple match models, highly reliable, long service life

6. The worm screw lift can be used as a standalone machine or in a production line.

7. The screw lift can accurately control and adjust the height of raising and pushing according to procedural needs.

8. The machine can be driven directly by a motor or other power source, as well as manual operation.

9. We produce different structures and types. The raising height can be customized as per customer requirements.

We offer two structure and mounting types:

Type 1: Axial movement – when the screw rod moves, it can be classified as rotation or non-rotation. Please pay attention to this detail when choosing your model

Type 2: Rotating movement: The nut moves in an axial movement.

Mounting type A: Screw rod or nut to move upwards

Mounting type B: Screw rod or nut moves downward

Instructions

1. When the pressure load is reduced, the rising height will increase.

2. When there is an increase in different loads, allowable torque, power and speed, the maximum powers for different work at continuous rates are different.

3. A screw lift with a screw motion structure that has also been lubricated must also be re-lubricated in the future based on different temperatures.

4. Information found in the parameter sheet are values for screw lifts that use grease lubrication.

5. The lubrication should be quickly changed during working times/

6. Working temperature: -20° - 80°C

7. The screw lift will self-lock in static conditions.

Links:https://globefindpro.com/products/51145.html

-

AAW-BS Screw Speed Reducer

AAW-BS Screw Speed Reducer

-

RV-C Industrial Robot Joint Speed Reducer

RV-C Industrial Robot Joint Speed Reducer

-

ATM-CR-S Double Shaft Steering Speed Reducer

ATM-CR-S Double Shaft Steering Speed Reducer

-

HAW Right Angle Speed Reducer

HAW Right Angle Speed Reducer

-

RV-E Industrial Robot Joint Speed Reducer

RV-E Industrial Robot Joint Speed Reducer

-

SHD Harmonic Drive Speed Reducer

SHD Harmonic Drive Speed Reducer

-

CSD Harmonic Drive Speed Reducer

CSD Harmonic Drive Speed Reducer

-

CSG Harmonic Drive Speed Reducer

CSG Harmonic Drive Speed Reducer

-

HT Steering Speed Reducer

HT Steering Speed Reducer

-

R Series Helical Gear Speed Reducer

R Series Helical Gear Speed Reducer

-

S Series Helical Gear Speed Reducer

S Series Helical Gear Speed Reducer

-

F Series Helical Gear Speed Reducer

F Series Helical Gear Speed Reducer