Ball Screw Jack

The SJB ball screw lift features a high quality square shell, and is equipped with a ball screw rod, guaranteeing the high transmission efficiency, precision and long service life. The service life of the screw lift is directly dependent on the service life of both the ball screw rod and the spare parts, such as the worm gear. Keep both of those working as designed, and the SJB ball screw lift will continue to work as required. The ball screw lift does not have a self-locking function, so we advise adding a brake to ensure the equipment's security.

Applications

These screw lifts are widely used in:

· Transmission units and digital control execution of machinery

· Roller motion devices in metallurgy

· Steel ladle lifting, turning over and movement transmission units in areas people can't go

· Lifting units and automatic or remote control opening/closing of large windows and doors

· Sluice gate opening in water conservation applications

· Large, flexible clamping, transposition tooling, welding robots

· Remote radar and solar energy sensing

· Medical equipment

· Lifting units on lift stages and in the automobile industry

| Model | SJB10 | SJB20 | SJB21 | SJB22 | SJB50 | SJB51 | SJB80 | SJB81 | SJB100 | SJB101 | SJB200 | SJB201 | SJB300 | |

| Max. Lift Force (KN) | 10 | 20 | 20 | 20 | 50 | 35 | 60 | 60 | 80 | 70 | 90 | 100 | 150 | |

| Rated Dynamic Load (KN) | 11 | 17 | 25 | 25 | 46 | 30 | 53 | 56 | 71 | 62 | 78 | 97 | 111 | |

| Screw diameter x lead (mm) | 20x5 | 32x5 | 32x10 | 32x20 | 40x10 | 40x20 | 50x10 | 50x20 | 63x10 | 63x20 | 80x10 | 80x20 | 100x20 | |

| Worm Gear Ratio | V1 | 1:4 | 1:6 | 1:6 | 1:6 | 1:7 | 1:7 | 1:8 | 1:8 | 1:8 | 1:8 | 1:8.75 | 1:8.75 | 1:10.25 |

| L1 | 1:16 | 1:24 | 1:24 | 1:24 | 1:28 | 1:28 | 1:32 | 1:32 | 1:32 | 1:32 | 1:35 | 1:35 | 1:41 | |

| Screw stroke/ 1 R of worm input (mm) | V1 | 1.25 | 0.83 | 1.67 | 3.34 | 1.43 | 2.86 | 1.25 | 2.5 | 1.25 | 2.5 | 1.14 | 2.28 | 1.95 |

| L1 | 0.31 | 0.21 | 0.42 | 0.84 | 0.36 | 0.72 | 0.31 | 0.62 | 0.31 | 0.62 | 0.29 | 0.58 | 0.488 | |

| Max. In/out Power (KW) | V1 | 0.57 | 1.14 | 1.14 | 1.14 | 2.2 | 2.2 | 2.5 | 2.5 | 3 | 3 | 4 | 4 | 7 |

| L1 | 0.27 | 0.55 | 0.55 | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | 3.5 | 3.5 | 5.5 | |

| Max. start torque with full load (Nm) | V1 | 4.8 | 8.2 | 15.3 | 29.2 | 34.4 | 47.4 | 36.8 | 72.3 | 49 | 82.9 | 53.2 | 118 | 157 |

| L1 | 1.8 | 3.4 | 6.3 | 12.1 | 14.6 | 19.4 | 15.3 | 29.9 | 20.4 | 34 | 23.4 | 52 | 66.7 | |

| Start Efficiency | V1 | 0.41 | 0.32 | 0.35 | 0.36 | 0.33 | 0.34 | 0.32 | 0.33 | 0.32 | 0.34 | 0.31 | 0.31 | 0.3 |

| L1 | 0.27 | 0.21 | 0.21 | 0.22 | 0.2 | 0.21 | 0.2 | 0.2 | 0.2 | 0.21 | 0.18 | 0.18 | 0.18 | |

| Rotating efficiency at 1500rpm | V1 | 0.59 | 0.58 | 0.62 | 0.65 | 0.59 | 0.6 | 0.58 | 0.59 | 0.58 | 0.62 | 0.55 | 0.55 | 0.53 |

| L1 | 0.42 | 0.39 | 0.42 | 0.44 | 0.39 | 0.41 | 0.39 | 0.4 | 0.39 | 0.41 | 0.35 | 0.35 | 0.35 | |

| Box Material | Modular Cast Iron | |||||||||||||

| Box Weight (kg) | 6 | 9.5 | 9.5 | 10 | 23 | 24 | 38 | 40 | 62 | 64 | 78 | 78 | 125 | |

| Screw rod +protective tube weight per 100mm (kg) | 0.57 | 0.8 | 0.8 | 0.8 | 1.6 | 1.6 | 2.5 | 2.5 | 3.2 | 3.2 | 4.6 | 4.6 | 7.3 | |

Features

1. The highest push speed reaches 77mm/s, due to the screw lift's high efficiency and low heating.

2. High efficiency: There are multiple balls between the screw shaft and nut. They carry out a rolling motion in order to reduce friction, and thus, increase the efficiency.

3. Stroke range: 6.5m

4. Standard screw lift precision levels are 0.02mm. The ball screw rod is produced using advanced Taiwanese production technology, and the milling, assembly, inspection and temperature/humidity working condition procedures are all strictly controlled. The use of an outstanding quality management system also guarantees the precision.

5. No backlash, high rigidity: The ball screw rod can ensure the radial backlash is a negative value due to pre-compression. By adding pressure to the balls, the repulsion of the balls enhances the rigidity of the hut when the screw lift is being used for mechanical devices.

6. Micro feeding: Because the screw rod starts using a ball motion, the starting torque is small with no scrambling, which ensures a precise micro-feeding.

7. Absolute mechanical synchronization, high precision, stable transmission.

8. High impact resistance

9. Rolling and precise ball screw lift are available

· Safety nut

· Ball screw rod imported from Taiwan

· Dust cover

· Anti-Backlash design

· Limit switch

· Overload clutch

· Potentiometer

· Encoder

· Brake

· Hand crank

This type of screw lifter is most often used in applications that require highly precise, and high quality automatic equipment. The working temperature is -20°- 40°C, though we do offer -40°- 70°C upon customer requests. We offer a double and three screw lead, with the lift speed proportionally increasing based on the number of screw leads.

Details

1. The SJB screw lift uses a special square groove housing in order to enhance the heat radiation ability of the shell and extend the service life of the grease.

2. The shell is made of nodular cast iron, which significantly improves the tensile strength and performance of the shell. It also extends the application range under both high and low temperatures.

3. A square rear cover ensures the screw rod does not automatically rotate when it does not need to.

4. A safety nut design monitors wear conditions of the screw lift and eliminates any hazards.

Download

Links:https://globefindpro.com/products/51153.html

-

HK Worm Gear Screw Jack

HK Worm Gear Screw Jack

-

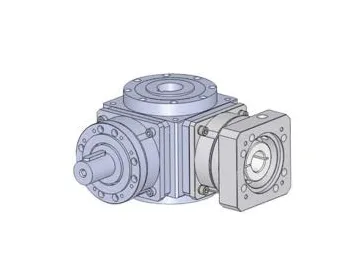

Bevel Steering Gearbox

Bevel Steering Gearbox

-

AT-2P Precision Steering Speed Reducer

AT-2P Precision Steering Speed Reducer

-

CSF Harmonic Drive Speed Reducer

CSF Harmonic Drive Speed Reducer

-

FHA-E Industrial Robot Joint Speed Reducer

FHA-E Industrial Robot Joint Speed Reducer

-

Cast Iron Worm Speed Reducer

Cast Iron Worm Speed Reducer

-

ATM-P-S Double Shaft Steering Speed Reducer

ATM-P-S Double Shaft Steering Speed Reducer

-

SHD Harmonic Drive Speed Reducer

SHD Harmonic Drive Speed Reducer

-

RV-E Industrial Robot Joint Speed Reducer

RV-E Industrial Robot Joint Speed Reducer

-

HAW Right Angle Speed Reducer

HAW Right Angle Speed Reducer

-

ATM-CR-S Double Shaft Steering Speed Reducer

ATM-CR-S Double Shaft Steering Speed Reducer

-

RV-C Industrial Robot Joint Speed Reducer

RV-C Industrial Robot Joint Speed Reducer