HK Worm Gear Screw Jack

Also known as a jack, the HK screw lift features a number of functions, including raising, falling, auxiliary pushing and turn over, making it suitable for a wide range of power sources. Some of those power sources include those driven by motors, directly by other power, or manually. The lift is most often used in low speed and heavy load applications.

Applications

· Platform lifting

· Working height adjustment in surface processing machines

· Tilt level adjustment of sliding transmission belts

· Working height modification in correctors

· Automatic opening and closing of large, industrial windows and doors

Technical Parameters

Capacity and Model Selection Parameters

| Model | Ratio | Input Shaft Speed 1800 r/min | Input Shaft Speed 1500 r/min | Input Shaft Speed 1200 r/min | Input Shaft Speed 900 r/min | Input Shaft Speed 600 r/min | Input Shaft Speed 300 r/min | ||||||||||||

| Power (Kw) | Lifting Force(Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force (Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force (Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force(Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force (Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force(Kg) | Lifting Speed (m/min) | ||

| HK-2T | 1/5 | 0.69 | 500 | 1.8 | 0.64 | 550 | 1.5 | 0.65 | 700 | 1.2 | 0.63 | 900 | 0.9 | 0.46 | 1000 | 0.6 | 0.37 | 1000 | 0.3 |

| 1/10 | 0.37 | 500 | 0.9 | 0.37 | 550 | 0.75 | 0.37 | 700 | 0.6 | 0.37 | 950 | 0.45 | 0.37 | 1000 | 0.3 | 0.19 | 1350 | 0.15 | |

| 1/20 | 0.37 | 600 | 0.45 | 0.37 | 700 | 0.38 | 0.37 | 900 | 0.3 | 0.37 | 1200 | 0.23 | 0.19 | 1350 | 0.15 | 0.19 | 1350 | 0.08 | |

| HK-3T | 1/6 | 0.98 | 700 | 1.8 | 0.93 | 800 | 1.5 | 0.88 | 950 | 1.2 | 0.91 | 1300 | 0.9 | 0.84 | 1800 | 0.6 | 0.42 | 1800 | 0.3 |

| 1/12 | 0.68 | 950 | 0.9 | 0.64 | 1100 | 0.75 | 0.61 | 1300 | 0.6 | 0.57 | 1650 | 0.45 | 0.46 | 2000 | 0.3 | 0.37 | 2000 | 0.15 | |

| 1/24 | 0.37 | 950 | 0.45 | 0.37 | 1100 | 0.38 | 0.37 | 1300 | 0.3 | 0.37 | 1650 | 0.23 | 0.37 | 2000 | 0.15 | 0.19 | 2000 | 0.08 | |

| HK-5T | 1/6 | 1.39 | 900 | 1.8 | 1.28 | 1000 | 1.5 | 1.24 | 1200 | 1.2 | 1.16 | 1500 | 0.9 | 0.87 | 1700 | 0.6 | 0.54 | 2100 | 0.3 |

| 1/12 | 1.1 | 1350 | 0.9 | 1.01 | 1500 | 0.75 | 0.98 | 1800 | 0.6 | 0.87 | 2150 | 0.45 | 0.58 | 2150 | 0.3 | 0.37 | 2500 | 0.15 | |

| 1/24 | 0.78 | 1800 | 0.45 | 0.72 | 2000 | 0.38 | 0.69 | 2400 | 0.3 | 0.55 | 2550 | 0.23 | 0.42 | 2900 | 0.15 | 0.37 | 2850 | 0.08 | |

| HK-10T | 1/8 | 2.12 | 1300 | 1.8 | 1.97 | 1450 | 1.5 | 1.85 | 1700 | 1.2 | 1.72 | 2100 | 0.9 | 1.66 | 3050 | 0.6 | 1.31 | 4800 | 0.30 |

| 1/16 | 1.12 | 1300 | 0.9 | 1.04 | 1450 | 0.75 | 0.98 | 1700 | 0.6 | 0.95 | 2200 | 0.45 | 0.87 | 3050 | 0.3 | 0.69 | 4800 | 0.15 | |

| 1/32 | 0.8 | 1750 | 0.45 | 0.75 | 1950 | 0.38 | 0.69 | 2250 | 0.3 | 0.64 | 2800 | 0.23 | 0.63 | 4100 | 0.15 | 0.48 | 6400 | 0.08 | |

| HK-15T | 1/8 | 2 | 1300 | 1.8 | 1.86 | 1450 | 1.5 | 1.75 | 1700 | 1.2 | 1.62 | 2100 | 0.9 | 1.57 | 3050 | 0.6 | 1.24 | 4800 | 0.30 |

| 1/16 | 1.06 | 1300 | 0.9 | 0.98 | 1450 | 0.75 | 0.93 | 1700 | 0.6 | 0.89 | 2200 | 0.45 | 0.83 | 3050 | 0.3 | 0.65 | 4800 | 0.15 | |

| 1/32 | 0.75 | 1750 | 0.45 | 0.7 | 1950 | 0.38 | 0.65 | 2250 | 0.3 | 0.61 | 2800 | 0.23 | 0.59 | 4100 | 0.15 | 0.46 | 6400 | 0.08 | |

| HK-20T | 1/10 | 2.66 | 1400 | 1.8 | 2.42 | 1850 | 1.5 | 2.25 | 1950 | 1.2 | 2.12 | 2450 | 0.9 | 1.93 | 3350 | 0.6 | 1.41 | 4900 | 0.30 |

| 1/20 | 1.42 | 1600 | 0.9 | 1.47 | 1850 | 0.75 | 1.37 | 2250 | 0.6 | 1.28 | 2800 | 0.45 | 1.18 | 3850 | 0.3 | 0.86 | 5600 | 0.15 | |

| 1/40 | 1.14 | 2400 | 0.45 | 1.17 | 2800 | 0.38 | 1.09 | 3350 | 0.3 | 1.07 | 4400 | 0.23 | 0.93 | 5750 | 0.15 | 0.69 | 8400 | 0.08 | |

| HK-30T | 1/12 | 3.62 | 1850 | 1.8 | 3.51 | 2150 | 1.5 | 3.39 | 2600 | 1.2 | 3.18 | 3250 | 0.9 | 2.94 | 4500 | 0.6 | 2.09 | 6400 | 0.30 |

| 1/18 | 2.65 | 1900 | 1.2 | 2.68 | 2300 | 1 | 2.57 | 2750 | 0.8 | 2.45 | 3500 | 0.6 | 2.19 | 4700 | 0.4 | 1.56 | 6700 | 0.2 | |

| 1/36 | 1.66 | 2200 | 0.6 | 1.63 | 2600 | 0.5 | 1.6 | 3200 | 0.4 | 1.47 | 3900 | 0.3 | 1.36 | 5400 | 0.2 | 1.2 | 9600 | 0.1 | |

| HK-40T | 1/12 | 4.15 | 1975 | 1.8 | 4.02 | 2300 | 1.5 | 3.81 | 2725 | 1.2 | 3.8 | 3625 | 0.9 | 3.48 | 4975 | 0.6 | 2.48 | 7050 | 0.30 |

| 1/18 | 3.2 | 2125 | 1.2 | 3.2 | 2550 | 1 | 3.04 | 3025 | 0.8 | 3.03 | 4025 | 0.6 | 2.74 | 5450 | 0.4 | 1.94 | 7725 | 0.2 | |

| 1/36 | 2.14 | 2625 | 0.6 | 2.07 | 3050 | 0.5 | 1.98 | 3650 | 0.4 | 1.99 | 4875 | 0.3 | 1.8 | 6600 | 0.2 | 1.41 | 10300 | 0.1 | |

| HK-50T | 1/7 | 9.47 | 2100 | 3.6 | 9.1 | 2450 | 3 | 9.02 | 2850 | 2.4 | 8.58 | 4000 | 1.8 | 8.2 | 5450 | 1.2 | 5.84 | 7750 | 0.6 |

| 1/14 | 5.76 | 2350 | 1.8 | 5.71 | 2800 | 1.5 | 5.57 | 3300 | 1.2 | 5.39 | 4550 | 0.9 | 5.06 | 6200 | 0.6 | 3.57 | 8750 | 0.30 | |

| 1/28 | 4.07 | 3050 | 0.9 | 3.89 | 3500 | 0.75 | 3.91 | 4100 | 0.6 | 3.65 | 5850 | 0.45 | 3.48 | 7800 | 0.3 | 2.45 | 11000 | 0.15 | |

| HK-100T | 1/8 | 16.3 | 3500 | 3.6 | 16.1 | 4000 | 3 | 15.8 | 5400 | 2.4 | 15.1 | 7100 | 1.8 | 14.8 | 9850 | 1.2 | 9.7 | 12950 | 0.6 |

| 1/16 | 11.7 | 4300 | 1.8 | 11.6 | 5400 | 1.5 | 10.5 | 7200 | 1.2 | 11 | 9450 | 0.9 | 9.62 | 11800 | 0.6 | 7.08 | 17350 | 0.30 | |

| 1/32 | 8.65 | 5500 | 0.9 | 9.55 | 6800 | 0.75 | 7.35 | 10000 | 0.6 | 7.53 | 14300 | 0.45 | 7.02 | 15750 | 03 | 5.84 | 26050 | 0.15 | |

Features

1. Compact structure, small volume, light weight

2. Extensive power source, no noise, convenient installation

3. Low speed, low frequency: Primarily used in process where a heavy load, low speed and non-frequent operation is needed.

4. Continuous loading: The trapezoid screw rod has a self-locking function that allows loading to occur without braking in between

5. Flexible applications, multiple functions, multiple match models, high reliability, long service life

6. The screw lift can be used separately or in a machine line.

7. The screw lift can accurately control and adjust the height of raising and pushing according to procedure requirements.

8. The screw lift can be directly driven by a motor or other power source, as well as manual power.

9. As we produce different structures and assembled types, the raising height can be customized according to customer requirements.

There are three mounting options:

1. Basic: The nut (worm gear) rotates, forcing the screw rod to move up and down. This is the most common mounted lift.

Note: When the screw rod lifts, a rotation force is created, which is not good for the lift. Measures must be taken to prevent rotation.

2. Stop rotating: This is best suited to operation when there is no top connection, as well as other applications where non-rotation can’t be achieved.

3. Movable nut: When users want to lengthen the stroke in a limited space, the movable nut screw lift is an ideal choice. When the stroke is longer, there must be support at the end of the shaft in order to achieve a better transmission efficiency.

1. How do I store the screw lift?

1) Keep the lift in a clean and dry place.

2) If it will be stored outdoors or in a humid location, wrap in a plastic bag, place in a box and take measures to prevent moisture buildup or external corrosion.

5. Warranty

The following costs and damages are not included in our warranty:

1) Shipping cost

2) If the lift connects with or is insert in a unit, if damage is incurred through dismounting or mounting on the unit, or damages incurred through improper usage, there will be added costs that are not covered under the warranty.

3) Other damages not caused by a manufacturing fault

1. Please select the model with the proper ratio and load based on your needs.

2. The surface temperature of the reducer and nut should be controlled in a range of -15 to 80℃ when the lift is operating.

3. Do not continuously run the lift. The load hour factor (T%) should not exceed 20% under a period of 30 minutes.

Load factor T%=Time under working/Circle x 100% Time under working/circle + interval/circle.

4. Ensure the drive source has a sufficient power supply.

5. The lift features a self-locking function. When this function is not working correctly, there will be a large impact and vibration.

6. Working conditions:

Place: Dry

Surrounding air: Normal/ no special requirements

Ambient temperature: -15℃~40℃

Relative Humidity: Below 85%

Links:https://globefindpro.com/products/51154.html

-

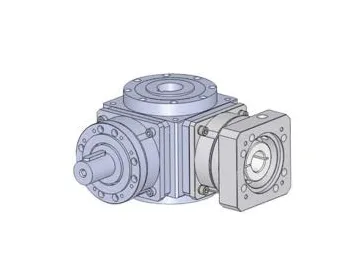

Bevel Steering Gearbox

Bevel Steering Gearbox

-

AT-2P Precision Steering Speed Reducer

AT-2P Precision Steering Speed Reducer

-

CSF Harmonic Drive Speed Reducer

CSF Harmonic Drive Speed Reducer

-

FHA-E Industrial Robot Joint Speed Reducer

FHA-E Industrial Robot Joint Speed Reducer

-

Cast Iron Worm Speed Reducer

Cast Iron Worm Speed Reducer

-

AT-P Precision Steering Speed Reducer

AT-P Precision Steering Speed Reducer

-

Ball Screw Jack

Ball Screw Jack

-

ATM-P-S Double Shaft Steering Speed Reducer

ATM-P-S Double Shaft Steering Speed Reducer

-

SHD Harmonic Drive Speed Reducer

SHD Harmonic Drive Speed Reducer

-

RV-E Industrial Robot Joint Speed Reducer

RV-E Industrial Robot Joint Speed Reducer

-

HAW Right Angle Speed Reducer

HAW Right Angle Speed Reducer

-

ATM-CR-S Double Shaft Steering Speed Reducer

ATM-CR-S Double Shaft Steering Speed Reducer