Tuopu

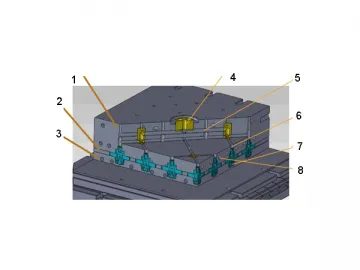

Tuopu is the largest rubber product enterprise in China. During this cooperation, we supply them with the design and manufacturing of 250T rubber injection molding machine, 16-nozzle cold runner and 64-cavity mould for auto bushing fabrication.

Client Demand

They require that the output capacity of this machine should reach 2 million pieces per year by using NBR as the raw material. They provide us product drawing and inspection standards.

Original Production Conditions

2 sets of machines are used for reaching expected product output. One of the 2 machines makes use of 32-cavity moulds and the other utilizes 24-cavity moulds. The usage cycle for each mould is 500 seconds and the material utilization rate is 70%.

Technical Hurdle

This client suggests that we can design the 48-cavity mould instead of the 64-cavity mould in view of their product characteristics for it would be very difficult for us to manufacture the 64-cavity mould. However, we are not intimidated by this difficulty and still successfully develop the 64-cavity mould, Therefore, the output demand of our client is sound ensured. And the final project result is better than our expectation.

Final Result

Through the unremitting endeavor, the material utilization rate is improved to 90% and the cycle time is shortened to 380 seconds. The production capacity of the machine reaches 12,800 pieces per day and the production efficiency is improved by 55%.

Links:https://globefindpro.com/products/61506.html

-

Gumarny Zubri

Gumarny Zubri

-

Project Schedule of Jiebao

Project Schedule of Jiebao

-

CM350L Portable Concrete Mixer

CM350L Portable Concrete Mixer

-

One-Card, Citizen Card and Residence Card

One-Card, Citizen Card and Residence Card

-

Online Transaction IC Card Terminal

Online Transaction IC Card Terminal

-

Steel Grating Production Lines

Steel Grating Production Lines

-

SHC1221 384k SIM Card Chips

SHC1221 384k SIM Card Chips

-

Conveyor Belt for Mines, Gravel Pits and Cement Plants

Conveyor Belt for Mines, Gravel Pits and Cement Plants

-

Hot Stamping Foil for PVC Panel

Hot Stamping Foil for PVC Panel

-

Manufacture Equipment

Manufacture Equipment

-

DAIHATSU

DAIHATSU

-

MAZ Front Wheel Bolt (DXR001)

MAZ Front Wheel Bolt (DXR001)