Project Schedule of Jiebao

1. Product Information

Product name: NR nylon mould base bushing 868

Size: 90mm outer diameter, 36mm thickness

Mould base: Aluminum (inside), nylon (outside)

Production conditions:

a. 34 moulds are used per 8 hours, each of which comes with 8 cavities. The material utilization rate is not high and the deflashing workload is huge.

b. The monthly output of similar products are nearly 2,000,000 pieces, needing about 10 sets of Longchang260T machines.

2. Doush Scheme

Bushing 868, 16-nozzle cold runner, 16-cavity mould, SE 250T rubber injection molding machine

3. Design Requirements

Equipment: SE 250T rubber injection molding machine

Mould: 600mm×650mm, 16 cavities

Cold runner: 16 nozzles

Cycle time: 8 minutes

Output per shift (8 hours): 57 pieces

Net weight of product: 63g

Runner loss: 3.64g/m×16=58.24g/m

Material utilization rate: 94%

Output capacity: 57 moulds×16=912 pieces/shift (8 hours), 2736×26 days=71136 pieces/month, 71136×11 months =782496 pieces/year

4. Project Investment (95W)

| a. BE 250T rubber injection molding machine (non-servo drive) | b. Cold runner mould=25W 15W=40W | c. Sliding plate system (mould shifting ejection) |

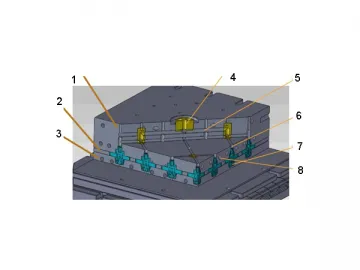

5. Cold Runner

a. 16 nozzles

b. Integral cold runner plate in good balance

c. 2 sets of oil temperature control systems making for excellent temperature uniformity

d. The stuck material can be easily removed.

e. The cold runner has excellent versatility. The center distance is 120mm.

1. Integral cold runner plate2. Thermal baffle 3. Heating platen 4. Main runner 5. 1/4 runner6. 1/16 runner7. 16 nozzles8. Cooling oil circuit |

6. Mould Shifting Procedures

| a. Mould return b. Mould base fixing c. Filled up cavities d. Shifting e. Opening f. Porduct removal |

7. Cycle Time Analysis

As shown in the figure, the whole cycle time for mould shifting is within 480s.

8. Production Cycle Analysis

| Cost composition | Machine, 16-nozzle cold runner, 16-cavity mould | Current production conditions |

| Output/shift (8 hours) | 57 moulds/shift (8 hours) ×16=912 pieces | 34 moulds/shift (8 hours)×8=272 pieces |

| Labor cost equipment depreciation electricity cost | 100 100 80=280 CNY/shift280/912=0.31 CNY/piece | 100 100 80=280 CNY/shift280/272=1.06 CNY/piece |

| Runner loss | Each mould: 120g/mould×20 CNY/kg=2.4 CNYEach piece: 2.4/16=0.15 CNY | Each mould: 100g/mould×20 CNY/kg=2 CNYEach piece: 2/8=0.25 CNY |

| Mould and cold runner amortization | Each piece: 150,000 CNY/200,000 moulds/16=0.046 CNYEach piece: 250,000 CNY/500,000 moulds/16=0.031 CNY | Each piece: 50,000 CNY/100,000 moulds/8=0.062 CNY |

| Total cost | 0.537 CNY/piece | 1.37 CNY/piece |

| Conclusion: As each product can save 0.83 CNY, the costs of cold runner and mould can be recovered if 500,000 pieces of products are manufactured (within 183 days), and the investment can be recouped from the saved costs within 7 months. | ||

Links:https://globefindpro.com/products/61510.html

-

CM350L Portable Concrete Mixer

CM350L Portable Concrete Mixer

-

One-Card, Citizen Card and Residence Card

One-Card, Citizen Card and Residence Card

-

Online Transaction IC Card Terminal

Online Transaction IC Card Terminal

-

Steel Grating Production Lines

Steel Grating Production Lines

-

JDC350 Stationary Mixer

JDC350 Stationary Mixer

-

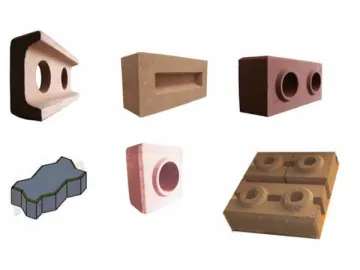

Block Type

Block Type

-

Gumarny Zubri

Gumarny Zubri

-

Tuopu

Tuopu

-

SHC1221 384k SIM Card Chips

SHC1221 384k SIM Card Chips

-

Conveyor Belt for Mines, Gravel Pits and Cement Plants

Conveyor Belt for Mines, Gravel Pits and Cement Plants

-

Hot Stamping Foil for PVC Panel

Hot Stamping Foil for PVC Panel

-

Manufacture Equipment

Manufacture Equipment