NDW Series Computerized Torsion Testing Machine

1. Main Usage

The NDW series computerized torsion testing machine possesses an efficient loading system. Through the AC servomotor and cycloidal pin gear speed reducer, the product drives the active clamps to rotate and load. Torque and torsion angles are tested by a high-precision torque sensor and an optical-electricity encoder. The computer dynamically shows a variety of data, including test torsion angle-torque curves, loading rates, peak values of test force, etc.

2. Major Technical Parameters of Computerized Torsion Testing Machine

1) Maximum test torque (Nm): 500、1000、2000

2) Relative error of test torque indicating value: ≤±1%

3) Measurement range of torsion angle: 0~9999.9°

4) Relative error of torsion angle: ≤±1%

5) Display of torsion angel: Minimum resolution 0.1°

6) Torsion angle through small-angle measurement: Displaying minimum resolution 0.0001°

7) Maximum distance between two clamps (mm): ≥500

8) Diameter of clamped sample (mm): φ6~φ20mm

9) Range of torsion speed: 0~540°/min, stepless speed regulation

10) Precision of speed: ≤1% indicating value

11) Rotation direction of test: Bidirectional

12) Power supply: 220V±10%, 50Hz

Related Names

Civil Material Tester | Metal Fatigue Test Equipment | Wire Torque Tester

Links:https://globefindpro.com/products/61720.html

-

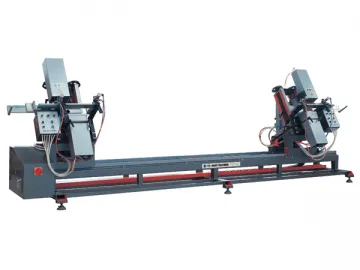

LJZ2A-450×3600 Double Mitre Saw

LJZ2A-450×3600 Double Mitre Saw

-

Vacuum Absorption Wood Router

Vacuum Absorption Wood Router

-

Precise Double Mitre Saw with Digital Measurement Display

Precise Double Mitre Saw with Digital Measurement Display

-

XJJ Series Simple Beam Impact Testing Machine

XJJ Series Simple Beam Impact Testing Machine

-

Three Head Seamless Welding Machine

Three Head Seamless Welding Machine

-

LJB2-350×3500 Double Mitre Saw

LJB2-350×3500 Double Mitre Saw

-

Four Point Multi-Layer Parallel Welding Machine

Four Point Multi-Layer Parallel Welding Machine

-

CNC Corner Cleaning Machine

CNC Corner Cleaning Machine

-

Electronic Broaching Machine for Impact Test

Electronic Broaching Machine for Impact Test

-

Lock-hole Processing Machine

Lock-hole Processing Machine

-

Corner Cleaning Machine

Corner Cleaning Machine

-

Double-head Water-slot Milling Machine

Double-head Water-slot Milling Machine