Rebar Upsetting and Threading Machine

Finished product

The rebar upsetting and threading machine is used to process the rebar for connection with the coupler. This actually involves two machines, i.e., rebar upsetting machine or cold forging press and rebar threading machine. The cold forging press is used for the upsetting of rebar end while the threading machine is used to cut threads onto the rebar end.

The rebar splicing involving upsetting and threading becomes a new trend in mechanical rebar connection field. It is perceived as the basic achievement in the construction industry because of its predominant objective conditions, practical economic profit and simple manipulation. This technology has made a great progress and become the most advanced in rebar connection. It realizes the high strength of deformed bar through cold extruding, integrates the merits of taper-threaded connection, and shows higher economic and social benefits than welding.

Machine Data

Rebar End Cold Forging Press

| Rebar diameter range | φ16 - φ40mm |

| Oil pump flux | 5L/min |

| Rated power | <60Mpa |

| Electric motor power | 4kw |

| Piston moving distance | 100mm |

| Out dimension | 1225×570×1100mm |

| Weight | 597kg |

Rebar Threading Machine

| Rebar diameter range | φ16-φ40mm |

| Thread cutting speed | 32r/min |

| Backing speed | 64r/min |

| Electric motor power | 2.4/3kw |

| Cutting head moving distance | 150mm |

| Out dimension | 1325×570×1070mm |

| Weight | 537kg |

Advantage of Upsetting Threading Connection

1.The joint strength reaches Grade SA.

2. This technology accelerates the processing speed and increases the production efficiency. Upsetting and threading one rebar end cost less than one minute.

3. After processed by our rebar upsetting and threading machine, the steel bars can be directly connected with a special coupler. This connection operation is not limited to climate or electricity.

4. The rebar upsetting and threading machine can be used to process the steel bars for building reinforcement cage.

5. The rebar splicing method involving upsetting and threading is material-saving, eco-friendly, and economical.

Rebar Processing Procedures

| Cutting The ends of the reinforcing bar is cut into flat surface. | |

| Cold Extruding The upsetting system performs in a patented method of enlarging the end of the reinforcement bar by cold extruding, increasing its core diameter. | |

| Threading The upset rebar end is cut into metric thread in accordance with ISO standard. Then this rebar is ready for connection under the help of a coupler. |

1. Rebar end cold extruding machine

2. Steel bar threading machine

3. Finished product: upsetting thread rebar and coupler

Links:https://globefindpro.com/products/62183.html

-

BSMJ Series Low Voltage Shunt Capacitor, Power Capacitor

BSMJ Series Low Voltage Shunt Capacitor, Power Capacitor

-

Marble Fountain

Marble Fountain

-

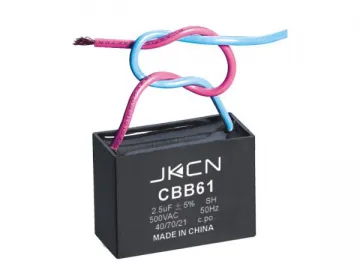

CBB AC Air Conditioner Motor Run Capacitor

CBB AC Air Conditioner Motor Run Capacitor

-

Marble Fireplace

Marble Fireplace

-

CBB Lighting Capacitor

CBB Lighting Capacitor

-

CBB AC Motor Run Capacitor

CBB AC Motor Run Capacitor

-

Marble Gazebo

Marble Gazebo

-

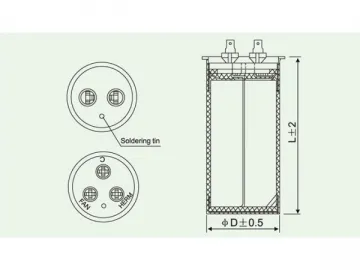

CBB Fan Capacitor

CBB Fan Capacitor

-

Power Capacitor Switching Device

Power Capacitor Switching Device

-

Power Compensation Capacitor Bank

Power Compensation Capacitor Bank

-

Cold Extrusion Thread Coupler

Cold Extrusion Thread Coupler

-

Steel Bar/Rebar Rib Peeling and Threading Machine

Steel Bar/Rebar Rib Peeling and Threading Machine