Automatic Carton Folding and Gluing Machine

Automatic Carton Folding and Gluing Machine

The carton folding and gluing machine is able to complete paperboard feeding, folding, gluing, pressing, shaping, and other steps automatically. Thus, the carton making process requires few workers, which helps save land occupation space and also largely improves production efficiency and reduces defective products caused by human factor.

The machine is mainly composed of the vacuum paperboard feeding unit, gluing and folding unit, as well as the counting and stacking unit. Except variable frequency motors, all other motors are all of Taiwain CPG brand. The maximum gluing speed is up to 130m/min and the average speed is 100m/min. The high working efficiency also helps reduce production cost.

Main Technical Specifications

Model | QF-2400 | QF-2700 |

Max. paperboard size | 900*2200 | 1200*2500 |

Min. paperboard size | 300*900 | 300*900 |

External dimension | L11000*W3000*H1600 | L12500*W3400*H1600 |

Equipment weight | 6500Kg | 7000Kg |

Power supply | 12KW 380V 50HZ | 12KW 380V 50HZ |

Paperboard thickness | Three/five ply paperboard | |

Control method | PLC touch screen control | |

Main Three Parts

1. The paperboard feeding unit of the automatic carton folding and gluing machine is applicable for bended cardboard as well. With high grade electromagnetic clutch, the unit can be independently controlled to assure simple and convenient operation. It adopts imported wearing resistant rubber belt for paper delivering.

2. The gluing and folding unit is designed with easy-cleaning stainless steel gluing rollers to assure uniform glue coating and avoid glue waste. The glue quantity can be electrically controlled as well. Meanwhile, the unit comes with a cardboard position correction device, and a paperboard creasing machine with adjustable creasing wheels. It is applicable for cardboards with thickness between 2mm and 8mm. The secondary creasing machine is also available to offer the second time creasing to some paperboards with unqualified creasing at the first time.

3. The counting and stacking unit for the automatic carton folding and gluing machine is digitally controlled, and supports data input without stopping the machine. In addition to automatic, accurate counting function, the unit also offers position correction function. The end products are pneumatically collected, fast and accurate.

Electrical Control System

1. The electrical system design of the machine conforms to European industry standard. The automatic carton folding and gluing machine comes with a color touch screen panel, and is controlled by Panasonic PLC controller, which reveals our user friendly design philosophy and simple equipment operation. The touch screen control panel and PLC controller are available with interfaces for future system upgrading.

2. The main motor speed is variable frequency controlled. The HOLIP VFD ensures smooth and steady motor operation, and helps reduce about 30% electricity consumption. It can also effectively protect the motor. When there is overheat, over current, over voltage, or low voltages conditions, the VFD will send out alarms and stop working. Corresponding alarming codes will also be displayed.

3. The contactors for motor control are all acquired from Siemens, and are additionally mounted with thermal overload relay, so as to protect the overloaded motors.

4. The connection wires are all connected by aviation plugs, assuring convenient maintenance, as well as simple connection and disconnection.

5. The front and rear ends of the automatic carton folding and gluing machine are both designed with operation buttons, allowing operators to operate the machine at either end. Made of stainless steel plate, the operation button panel is aesthetical and durable. With both graphic and text to describe the function of buttons, the button panel is easy to use.

Brand List

Part name | Brand |

Touch screen | Kunluntongtai |

PLC | Panasonic |

VFD | HOLIP |

Intermediate relay | OMRON |

Optoelectronic switch | Hugong |

Switching power supply | Mean Well |

Thermal overload relay | CHINT |

Circuit breaker | CHINT |

Position switch | CHINT |

Contactor | Siemens |

Buttons | Schneider |

Links:https://globefindpro.com/products/62821.html

-

GM-C Double Layer Corrugated Paperboard Gluing Machine

GM-C Double Layer Corrugated Paperboard Gluing Machine

-

Process Flow

Process Flow

-

TMJ Automatic Box Flute Laminating Machine

TMJ Automatic Box Flute Laminating Machine

-

Box Stitching Machine

Box Stitching Machine

-

SF-280S Type Fingerless Single Facer For Corrugated Paperboard

SF-280S Type Fingerless Single Facer For Corrugated Paperboard

-

Flatbed Die Cutting Machine

Flatbed Die Cutting Machine

-

Corrugated Paper Hydraulic Shaftless Mill Roll Stand

Corrugated Paper Hydraulic Shaftless Mill Roll Stand

-

Shopping Center in Singapore

Shopping Center in Singapore

-

Hotel Chain in Mexico

Hotel Chain in Mexico

-

SM-E Corrugated Paperboard Double Facer

SM-E Corrugated Paperboard Double Facer

-

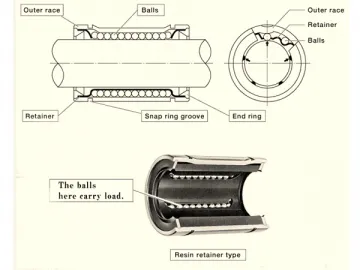

Linear Bearing

Linear Bearing

-

4870Kg Fuel Tank Truck

4870Kg Fuel Tank Truck