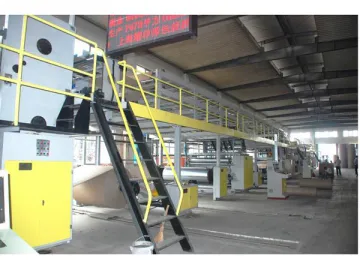

Double Deck Cardboard Conveyor Bridge

Double Deck Cardboard Conveyor Bridge

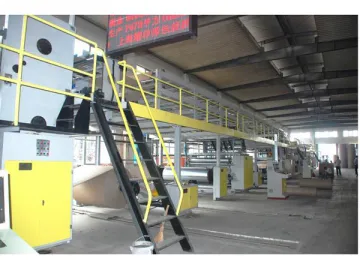

The double deck cardboard conveyor bridge is used to transfer the single-sided corrugated paperboard from the underneath single facer to the multiplex pre-heater for preheating as well as to the gluing machine and double facer for gluing and shaping. It functions as a bridge-type delivering system which carries the single face corrugated cardboard directly to the suction strainer.

The lifter of the overbridge conveyor is attached with the synchronous motor drive and programmable logic controller to ensure synchronization with the single facer. The bridge comes with two lines of guardrails and three ladders to ensure operating safety and convenience. The passageway is constructed of 50mm×50mm angle irons and antiskid plates of 600mm in width. Moreover, a couple of operation panels are installed for electric control of the conveyor. The panel can be mounted onto the overbridge or below the overbridge.

The double deck cardboard conveyor bridge includes a suction strainer with the adjustable suction and tension force. This suction system uses high-voltage and variable-frequency centrifugal blower for vacuum suction and straining of the cardboard. It is also able to make electrical corrections of deviation in the traveling direction of the cardboard. This ensures that the cardboard is flat and firmly adhered to the belt. In addition, deviation correction can be conducted both on and off the overbridge conveyor.

This series of conveyor includes the paper feeding stand with two groups of slope conveyor belts. The conveying and stacking speeds are set slow so as to enable the overlapping of the wavy fluted forms, which saves storing space and facilitates paperboards storing.

Features

1. Maximum width of the paper: 1800mm

2. Making material of the main conveying frame: No.16 channel steel

3. There are two sets of paper conveying stands attached to the base of the single facer and bridged over the pre-heater. The stands are also equipped with air suction device.

4. The conveying belt carries paperboard onto the bridge. It is powered by the 5HP×4P motor with variable frequency drive to ensure synchronization of the belt with the single facer.

5. Specifications of the conveyor belt: W800×L3100×5T×4pcs

W1200×L3140×5T×4pcs

6. The paper guide board of the control panel is driven the helical gear and numeric controlled. It can be manually adjusted on the stand or operated off the stand.

The double deck cardboard conveyor bridge is used to transfer the single-sided corrugated paperboard from the underneath single facer to the multiplex pre-heater for preheating as well as to the gluing machine and double facer for gluing and shaping. It functions as a bridge-type delivering system which carries the single face corrugated cardboard directly to the suction strainer.

The lifter of the overbridge conveyor is attached with the synchronous motor drive and programmable logic controller to ensure synchronization with the single facer. The bridge comes with two lines of guardrails and three ladders to ensure operating safety and convenience. The passageway is constructed of 50mm×50mm angle irons and antiskid plates of 600mm in width. Moreover, a couple of operation panels are installed for electric control of the conveyor. The panel can be mounted onto the overbridge or below the overbridge.

The double deck cardboard conveyor bridge includes a suction strainer with the adjustable suction and tension force. This suction system uses high-voltage and variable-frequency centrifugal blower for vacuum suction and straining of the cardboard. It is also able to make electrical corrections of deviation in the traveling direction of the cardboard. This ensures that the cardboard is flat and firmly adhered to the belt. In addition, deviation correction can be conducted both on and off the overbridge conveyor.

This series of conveyor includes the paper feeding stand with two groups of slope conveyor belts. The conveying and stacking speeds are set slow so as to enable the overlapping of the wavy fluted forms, which saves storing space and facilitates paperboards storing.

Features

1. Maximum width of the paper: 1800mm

2. Making material of the main conveying frame: No.16 channel steel

3. There are two sets of paper conveying stands attached to the base of the single facer and bridged over the pre-heater. The stands are also equipped with air suction device.

4. The conveying belt carries paperboard onto the bridge. It is powered by the 5HP×4P motor with variable frequency drive to ensure synchronization of the belt with the single facer.

5. Specifications of the conveyor belt: W800×L3100×5T×4pcs

W1200×L3140×5T×4pcs

6. The paper guide board of the control panel is driven the helical gear and numeric controlled. It can be manually adjusted on the stand or operated off the stand.

Related Names

Double Deck Crate Conveyor System | Double Layer Conveyor

Scan QR to Read

Links:https://globefindpro.com/products/63803.html

Links:https://globefindpro.com/products/63803.html

Recommended Products

Hot Products