Paper Board Single Facer

Paper Board Single Facer

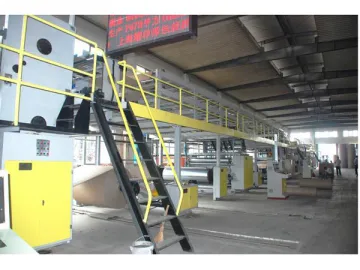

The paper board single facer is designed to produce single-sided corrugated paper. Corrugated medium is firstly formed into a fluted pattern, then supplied with starch-based glue on its surface, and finally joined to a flat linerboard to form the corrugated paperboard.

The driving section of the single facer consists of a driving box with split structure and universal joint transmission. This independent design keeps the vibration source apart from the main machine, ensuring convenient maintenance, stable transmission, and reliable operation at a high speed. In addition, the reducer casing combines the closed type gear transmission with oil bath lubrication in reducing the vibration impact on the machine. The main drive employs the variable-frequency motor and PLC system to keep the same speed with the production line.

The independent adhesive coating section is attached with guide rails. It can be easily and completely removed from the main machine for maintenance and repair. Its glue roller surface is treated with special mesh nicking and chrome plating. The glue coating device can realize automatic glue re-circulation and pneumatic control over the glue coating and refilling. Its unique intrusive design can enlarge the contact area between the gluing roller and the glue. In addition, the gap between the glue coating rollers can be adjusted. The device can be supplied with the digital gap display, auto tracking gap-adjust, and speed regulation functions upon customers’ request.

Specifications

1. Maximum design speed: 180m/min

2. Normal working speed: 150-180m/min

3. Maximum work speed: 160m/min

4. Paper standard: grade A.

5. Face paper: 140-175g/ m2

6. Paper standard: Grad A

7. Liner paper: 140-175g/ m2

8. Medium paper: 110-125g/ m2

9. Maximum width of the paper roll: 1800mm

10. Machine width: 4250mm

11. Machine height: 1750mm

12. Machine weight: 5200kg

13. Driving motor: 40HP×4P/1.8M

14. Vacuum suction system power: 15HP/1.8M

15. Steam pressure: 10~14kg/ cm2

16. Geared wheel type: UV type

17. Geared wheel: 2pcs×Φ360mm

18. Making material of geared wheel: 48CrMo alloy steel (made in Shanghai or Jiangsu Province)

19. Flute size: A, C, B, or E ( Various size options are available upon customers’ request.)

20. Pressure roller: 1pc×Φ380mm

21. Making material of pressure roller: hard steel

22. Surface treatment of pressure roller: grinding and chroming

23. Gluing roller: 1pc×Φ250mm

24. Surface treatment of gluing roller: grinding, embossing, and chroming

25. Doctor roller: 1pc×Φ140mm

26. Surface treatment of doctor roller: grinding, chroming, and polishing.

Features

1. The upper and lower corrugating rollers are individually controlled by two hydraulic cylinders. The cylinder adopts the hydraulic station control and is attached with a solenoid valve. Its specification isΦ140mm×ST(45 45).

2. The glue roller is controlled by two pneumatic cylinders. The specification of cylinder is Φ100mm×ST30 and also attached with a solenoid valve.

3. Glue thickness adjustment can be realized via the geared wheels of the electric motor by modulating the clearance between the glue roller and doctor roller. The friendly user-interface design can display gluing details. The specification of the electric motor is GH1/8HP×4P×1/4680. The gear reducer motor is made in Taiwan.

4. The clearance between two pressure wheels can also be regulated by the geared wheels of the electric motor.

5. The main drive adopts the gear box variable speed transmission. The gear box can transfer the kinetic energy to the three rollers including the upper, lower corrugating roller, and pressure roller via the universal transmission shaft. Its unique structure ensures a stable performance, easy, and fast maintenance. The gear is oil-immersed and made of high quality alloy steel through grinding treatment. It creates low noise during operation and can maintain a long service life.

6. The gluing roller adopts the gear reducer motor to avoid glue drying on the roller. The motor is supplied by Taiwan CPG Company. Its specification is GH1/HP×4P×1/30.

7. Three steam swivel joints, steam hoses, and backwater equipment are available.

8. The iron covering on the top of the machine can be taken apart when users need clean the garbage inside the machine. There is no need to disassemble the whole machine during cleaning.

9. The shafts of the upper, lower corrugating rollers, and pressure roller employ the high-temperature resistant grease for lubrication. Shaft bearings such as NJ224 and NU224 are high precision bearings imported from Japan.

The paper board single facer is designed to produce single-sided corrugated paper. Corrugated medium is firstly formed into a fluted pattern, then supplied with starch-based glue on its surface, and finally joined to a flat linerboard to form the corrugated paperboard.

The driving section of the single facer consists of a driving box with split structure and universal joint transmission. This independent design keeps the vibration source apart from the main machine, ensuring convenient maintenance, stable transmission, and reliable operation at a high speed. In addition, the reducer casing combines the closed type gear transmission with oil bath lubrication in reducing the vibration impact on the machine. The main drive employs the variable-frequency motor and PLC system to keep the same speed with the production line.

The independent adhesive coating section is attached with guide rails. It can be easily and completely removed from the main machine for maintenance and repair. Its glue roller surface is treated with special mesh nicking and chrome plating. The glue coating device can realize automatic glue re-circulation and pneumatic control over the glue coating and refilling. Its unique intrusive design can enlarge the contact area between the gluing roller and the glue. In addition, the gap between the glue coating rollers can be adjusted. The device can be supplied with the digital gap display, auto tracking gap-adjust, and speed regulation functions upon customers’ request.

Specifications

1. Maximum design speed: 180m/min

2. Normal working speed: 150-180m/min

3. Maximum work speed: 160m/min

4. Paper standard: grade A.

5. Face paper: 140-175g/ m2

6. Paper standard: Grad A

7. Liner paper: 140-175g/ m2

8. Medium paper: 110-125g/ m2

9. Maximum width of the paper roll: 1800mm

10. Machine width: 4250mm

11. Machine height: 1750mm

12. Machine weight: 5200kg

13. Driving motor: 40HP×4P/1.8M

14. Vacuum suction system power: 15HP/1.8M

15. Steam pressure: 10~14kg/ cm2

16. Geared wheel type: UV type

17. Geared wheel: 2pcs×Φ360mm

18. Making material of geared wheel: 48CrMo alloy steel (made in Shanghai or Jiangsu Province)

19. Flute size: A, C, B, or E ( Various size options are available upon customers’ request.)

20. Pressure roller: 1pc×Φ380mm

21. Making material of pressure roller: hard steel

22. Surface treatment of pressure roller: grinding and chroming

23. Gluing roller: 1pc×Φ250mm

24. Surface treatment of gluing roller: grinding, embossing, and chroming

25. Doctor roller: 1pc×Φ140mm

26. Surface treatment of doctor roller: grinding, chroming, and polishing.

Features

1. The upper and lower corrugating rollers are individually controlled by two hydraulic cylinders. The cylinder adopts the hydraulic station control and is attached with a solenoid valve. Its specification isΦ140mm×ST(45 45).

2. The glue roller is controlled by two pneumatic cylinders. The specification of cylinder is Φ100mm×ST30 and also attached with a solenoid valve.

3. Glue thickness adjustment can be realized via the geared wheels of the electric motor by modulating the clearance between the glue roller and doctor roller. The friendly user-interface design can display gluing details. The specification of the electric motor is GH1/8HP×4P×1/4680. The gear reducer motor is made in Taiwan.

4. The clearance between two pressure wheels can also be regulated by the geared wheels of the electric motor.

5. The main drive adopts the gear box variable speed transmission. The gear box can transfer the kinetic energy to the three rollers including the upper, lower corrugating roller, and pressure roller via the universal transmission shaft. Its unique structure ensures a stable performance, easy, and fast maintenance. The gear is oil-immersed and made of high quality alloy steel through grinding treatment. It creates low noise during operation and can maintain a long service life.

6. The gluing roller adopts the gear reducer motor to avoid glue drying on the roller. The motor is supplied by Taiwan CPG Company. Its specification is GH1/HP×4P×1/30.

7. Three steam swivel joints, steam hoses, and backwater equipment are available.

8. The iron covering on the top of the machine can be taken apart when users need clean the garbage inside the machine. There is no need to disassemble the whole machine during cleaning.

9. The shafts of the upper, lower corrugating rollers, and pressure roller employ the high-temperature resistant grease for lubrication. Shaft bearings such as NJ224 and NU224 are high precision bearings imported from Japan.

Related Names

Single Face Cardboard Making Machine | Single Sided Corrugated Board Forming Machine

Scan QR to Read

Links:https://globefindpro.com/products/63810.html

Links:https://globefindpro.com/products/63810.html

Recommended Products

-

Collagen

Collagen

-

High Speed Carton Stitching Machine

High Speed Carton Stitching Machine

-

Cardboard Slitter Scorer With Thin Blade

Cardboard Slitter Scorer With Thin Blade

-

Semi Automatic Gluer Machine

Semi Automatic Gluer Machine

-

Corrugated Cardboard Hydraulic Mill Roll Stand

Corrugated Cardboard Hydraulic Mill Roll Stand

-

NC Thin Blade Slitter Scorer

NC Thin Blade Slitter Scorer

-

XLD-L043 Street Lamp

XLD-L043 Street Lamp

-

Conical Steel Light Pole

Conical Steel Light Pole

-

Fluted Steel Light Pole

Fluted Steel Light Pole

-

XLD-L045 Street Lamp

XLD-L045 Street Lamp

-

XLD-L046 Street Lamp

XLD-L046 Street Lamp

-

Double Deck Cardboard Conveyor Bridge

Double Deck Cardboard Conveyor Bridge