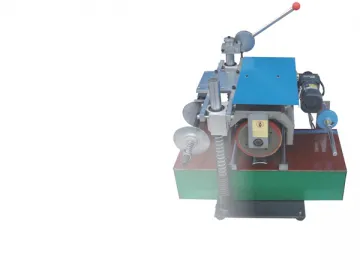

Edge Milling Machine

Edge Milling Machine

Edge milling machine is the advanced and efficient milling equipment, and it uses milling technology rather than planing technology. It can be applied for processing straight edge, bevel edge and U shape groove before welding operation, and it can take place of edge planing machine for groove machining process. This product is suitable for welding, especially automatic welding operation. Meanwhile, it can improve the working efficiency and product quality, and cut down the labor intensity and energy consumption. In addition, it uses loose package, and the electrical control cabinet is in the plywood case. Based on the great performance and low price, our edge milling machine is widely used in the equipment manufacturing process, such as boiler, pressure vessel, ship, machinery, electrical and chemical equipment, etc.

Technical Parameters

Model | XBJ-6 | XBJ-9 | XBJ-12 | XBJ-15 |

Max. Steel Plate Length (mm) | 6000 | 9000 | 12000 | 15000 |

Steel Plate Thickness (mm) | 6-50 | |||

Milling Angle (°) | 0-45 | |||

Milling Travel Speed (mm/min) | 165-1650 | |||

Milling Return Speed (mm/min) | 5000 | |||

Milling Cutter Rotation Speed (rpm) | 125-800 | |||

Number of Hydraulic Cylinder | 8 | 11 | 15 | 18 |

Working Pressure (Mpa) | 3.5 | |||

Table Height (mm) | 900 | |||

Machine Size (mm) | 7724×2600×2050 | 10724×2600×2050 | 13724×2600×2050 | 16724×2600×2050 |

Users should be familiar with the properties of our edge milling machine, and the following items need to be checked before use.

1. Oil level in the hydraulic tank of headstock transmission should not be lower than the standard line.

2. Add pure lubricating oil to the lubricating parts.

3. Make sure that the wire connections are in normal condition and the rotation direction of motor is correct.

4. Turn on the control power supply, and the oil pump of motor should be off. Then, press the start button, and check if the solenoid valve of relay works normally.

5. Start the motor, and check whether the sound generated during working is normal.

6. Start the oil pump and make sure it is in good working condition.

7. Make sure that the pressure revealed by the pressure gage is acceptable, and whether it keeps still.

After the items above are checked, you can carry out idle running process, and you need to pay attention to the following details.

1. The transmission of headstock should be in good working state.

2. No shaking phenomenon occurs when the piston rod of the oil cylinder moves. Meanwhile, oil leakage, oil penetration and air should also be avoided.

3. Make sure that there is no oil leakage or oil penetration problem in the hydraulic pipeline and oil tank.

4. Keep the limit switch and button in good state.

5. Check if the positioning block retracts into the lathe bed totally, and if splash guard collides with the workpiece.

Links:https://globefindpro.com/products/64163.html

-

Super Heavy Duty Auto Welding Manipulator

Super Heavy Duty Auto Welding Manipulator

-

European Standard Car License Plate Frame

European Standard Car License Plate Frame

-

Adjustable Welding Rotator

Adjustable Welding Rotator

-

Hot-Transfer Printing Machine

Hot-Transfer Printing Machine

-

Wind Tower Production Line

Wind Tower Production Line

-

Circular Seam Welding Machine

Circular Seam Welding Machine

-

Metal Punching Machine

Metal Punching Machine

-

Electric Torque Wrench NVL-21TE

Electric Torque Wrench NVL-21TE

-

Electric Torque Wrench NSY-5TE

Electric Torque Wrench NSY-5TE

-

Electric Torque Wrench T-9

Electric Torque Wrench T-9

-

Electric Torque Wrench NVL-25TE

Electric Torque Wrench NVL-25TE

-

Electric Torque Wrench NEL-40TE

Electric Torque Wrench NEL-40TE