Wind Tower Production Line

Wind Tower Production Line

Based on the successful deign cases and advanced manufacturing technology in the world, we develop this wind tower production line, and this system mainly contains CNC cutting machine, edge milling machine, welding manipulator, welding rotator and welding system. In addition, our product adopts loose package, and the electrical control cabinet is in the plywood case.

Until now, our company has supplied a large number of machines for many wind power generating projects around the world. The single wind tower we supplied for Shanghai Zhenhua Heavy Industries Co., Ltd is as heavy as 800 tons, which is the heaviest in China.

Reeling Equipment

Steel Plate Cutting

Workpiece Butt Welding

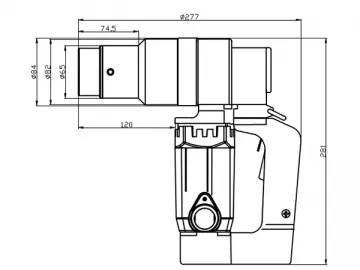

Our wind tower production line uses CNC flame or CNC plasma cutting machine to finish the cutting process of different plates simultaneously. The applied edge milling machine can be used for groove processing before welding, and it is suitable for various kinds of low carbon steel plates, stainless steel plates and aluminum plates. It can process straight edge, bevel edge or U shape groove in one step, and it features low price, high working efficiency, low energy consumption, good smoothness, convenient operation and maintenance, etc. Meanwhile, our welding manipulator consists of column, boom, rotation mechanism, travelling trolley and other components. Bend welding structural parts are applied to produce the column and boom, so the great rigidity is guaranteed. In addition, guide rail is adopted by the manipulator, and the rail is processed with grinding and high frequency hardening treatments which can ensure the high precision and abrasion proof property of rail.

Links:https://globefindpro.com/products/64168.html

-

Circular Seam Welding Machine

Circular Seam Welding Machine

-

Custom American Number Plate Frame

Custom American Number Plate Frame

-

Pipe Processing Line

Pipe Processing Line

-

Machine Parts

Machine Parts

-

Electric Shear Wrench SAL-24E

Electric Shear Wrench SAL-24E

-

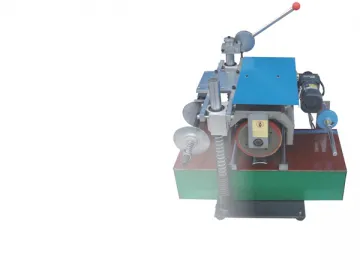

Roll Printing Machine

Roll Printing Machine

-

Hot-Transfer Printing Machine

Hot-Transfer Printing Machine

-

Adjustable Welding Rotator

Adjustable Welding Rotator

-

European Standard Car License Plate Frame

European Standard Car License Plate Frame

-

Super Heavy Duty Auto Welding Manipulator

Super Heavy Duty Auto Welding Manipulator

-

Edge Milling Machine

Edge Milling Machine

-

Metal Punching Machine

Metal Punching Machine