Ribbon Blender

Application

Our SLHY series of ribbon blenders are suitable for blending powdery materials in compound feed factories to ensure the ingredients are evenly distributed, guaranteeing the quality of the finished compound feed.

Features

1. The powder mixing machine is a horizontal batch mixer equipped with a double layer of ribbon blades.

2. Its discharge outlet comes with the same length as the blending machine, and is set at the bottom of the machine base. This design allows materials to be discharged quickly. The discharge door on the horizontal blender is pneumatically controlled.

3. Our ribbon blender has a liquid addition pipe inside, enabling oil or other liquid to be added to the machine.

4. This powder mixer revolves at a slow speed to gently but effectively and efficiently mix materials with less residue.

5. The ribbon blender achieves a high blending uniformity with CV (coefficient of variation) that is no more than 7%.

6. Both carbon steel blenders and stainless steel blenders are available from our company.

Technical Parameters of Ribbon Blender

| Item Model | Effective volume | Blending quantity per batch | Blending time per batch | Blending uniformity | Power |

| m3 | kg | min | CV% ≤ | kW | |

| SLHY0.4 | 0.4 | 200 | 3~6 | 7 | 5.5 |

| SLHY0.6 | 0.6 | 300 | 3~6 | 7 | 5.5 |

| SLHY1 | 1 | 500 | 3~6 | 7 | 11 |

| SLHY2.5 | 2.5 | 1000 | 3~6 | 7 | 18.5 |

| SLHY5 | 5 | 2000 | 3~6 | 7 | 30 |

| SLHY7.5 | 7.5 | 3000 | 3~6 | 7 | 37 |

| SLHY10 | 10 | 4000 | 3~6 | 7 | 45 |

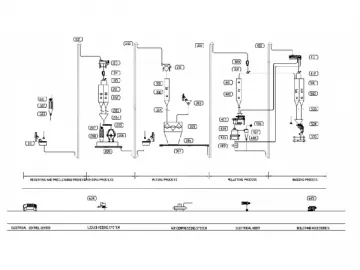

Structure and Working Principle

The ribbon blender has two layers of rotor blades. The inner layer revolves counterclockwise, and the outer layer revolves clockwise. When the rotor on the mixing equipment is rotating, the counterclockwise blades push materials from one side to the other, while the clockwise blades push the materials in the opposite direction. This leads to a uniform blending due to the repeated convectional movement of the material, stirring of the material on the side plates, as well as gravitational action.

Links:https://globefindpro.com/products/70184.html