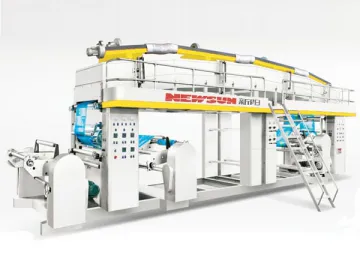

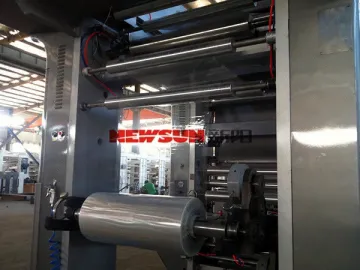

QDF Series High-Speed Dry Laminating Machine

The QDF series high-speed dry laminating machine delivers you the important benefits in the form of outstanding finished products featuring high strength, sterling quality and high temperature resistance. Our roll material laminating equipment offers repeatable composition to two layers materials including BOPP, PET, CPP, aluminum foil and paper, etc.

This series of high-speed dry laminating machine is available in 3 different models which are QDF-600, QDF-800 and QDF-1000. The maximum web width that these plastic film laminators offer reaches 600mm-1000mm, and the highest capacity is 120m/min.

Advantages

1. The main motors in this aluminum foil laminator are adjusted by variable frequency drive synchronously, thus making operation to be more reliable.

2. Glue feeding falls into two methods that are anilox roller and rubber covered roller.

3. This high-speed dry laminating machine uses pneumatic jack for heating oven, and guide rollers inside the oven are drive rollers.

4. In the drying tunnel of our paper laminator, there are four sections and temperature of each section is individually controlled.

5. The first unwinding unit involves the utilization of automatic tension control and photoelectric sensor for correction.

6. Both unwinding and rewinding units are fitted with double winding stations, thus realizing continuous operation.

7. Composite rollers and oil heating system offer consistent temperature to this soft packing machinery.

| Model | QDF-600 | QDF-800 | QDF-1000 |

| Laminating Width | 600mm | 800mm | 1000mm |

| Laminating Layer Quantity | 2 | 2 | 2 |

| Laminating Speed | 10-120m/min | 10-120m/min | 10-120m/min |

| Unwinding Diameter | 750mm | 750mm | 750mm |

| Dry Oven Temperate | 120 ℃ | 120 ℃ | 120 ℃ |

| Total Power | 48kW | 52kW | 58kW |

| Weight | 7500kb | 8200kb | 8900kg |

| Overall Dimensions (L×W×H) | 9600mm×2400mm×3300mm | 9600mm×2650mm×3300mm | 9600mm×2850mm×3300mm |

Other Picture

Links:https://globefindpro.com/products/74281.html

-

Yuchai Engines

Yuchai Engines

-

Yuchai Marine Generator Sets

Yuchai Marine Generator Sets

-

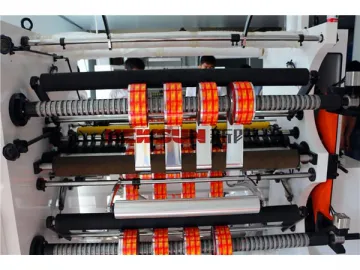

FHQZ Series High-Speed Slitting and Rewinding Machine

FHQZ Series High-Speed Slitting and Rewinding Machine

-

QDTJ-400B Series Hot Stamping Machine

QDTJ-400B Series Hot Stamping Machine

-

FHQJ Series High-Speed Slitter Rewinder

FHQJ Series High-Speed Slitter Rewinder

-

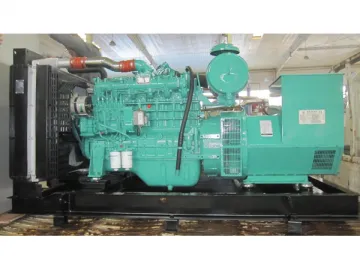

Cummins Engines

Cummins Engines

-

SDEC Diesel Generator Sets

SDEC Diesel Generator Sets

-

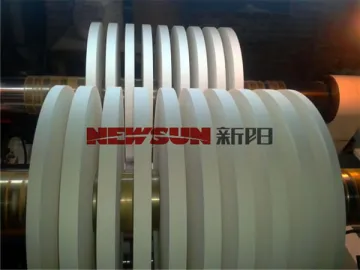

FHQR Series High-Speed Slitter Rewinder

FHQR Series High-Speed Slitter Rewinder

-

ZFJ Series Slitter Rewinder for Paper and Aluminum Foil

ZFJ Series Slitter Rewinder for Paper and Aluminum Foil

-

Yuchai Diesel Generator Sets

Yuchai Diesel Generator Sets

-

ASY-E Series High-Speed Rotogravure Printing Machine

ASY-E Series High-Speed Rotogravure Printing Machine

-

ASY-B Series Rotogravure Printing Machine

ASY-B Series Rotogravure Printing Machine