FHQJ Series High-Speed Slitter Rewinder

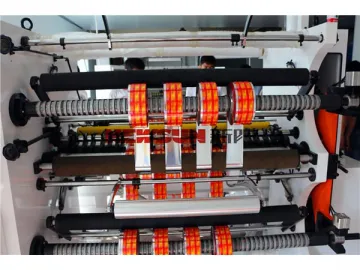

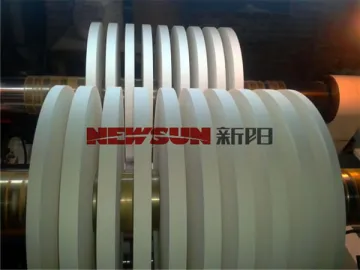

The FHQJ series high-speed slitter rewinder is practically designed to process various kinds of roll materials including BOPP, PET, CPP and PVC, etc. With the aid of this printing machinery, you will benefit from outstanding slitting capacity of 400m/min. The maximal unwinding diameter reaches 600/800mm and the minimal is only 30mm. Most demanding needs for slitting can be accommodated.

Advantages

1. PLC and touch screen are introduced to the electrical control system of this high-speed slitter rewinder, whereby offering intuitive read-out and easy configuration.

2. In this multi-functional slitter rewinder, the rewinding unit involves the utilization of vector frequency converter while unwinding unit adopts magnetic powder brake. Both units are controlled by PLC for automatic diameter calculation and tension control.

3. Shaftless pneumatic mechanism is introduced to unwinding unit, resulting in remarkable efficiency. Guiding system is available for accuracy. Optional hydraulic feeding system is offered.

4. Our high-speed slitter rewinder is fitted with duplex differential slip rewind inflatable shafts and razor blades, offering smooth cutting. Air blowing system is used to collect waste materials.

5. This packaging film slitter rewinder comes with functions of metering and automatic shutdown, etc.

6. We pour well-conceived design concept into the fabrication of this series of high-speed slitter rewinder, thus offering mechanical, electrical and hydraulic properties, as well as protective devices.

| Model | FHQJ-1300 |

| Max. Web Width | 1300mm |

| Max. Unwinding Diameter | Φ600/800mm |

| Max. Machine Speed | 400m/min |

| Max. Rewinding Diameter | 500mm |

| Min. Slitting and Rewinding Width | 30mm |

| Inspection Accuracy | ±0.4mm |

| Thickness of Raw Material | 0.012-0.2mm |

| Machine Weight | 3500kg |

| Total Power | 9kW |

| Overall Dimension (L×W×H) | 2500×4200×2000mm |

Links:https://globefindpro.com/products/74286.html

-

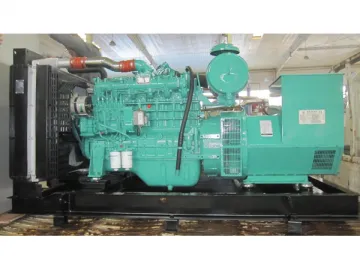

Cummins Engines

Cummins Engines

-

Accessories

Accessories

-

ASYQD-E Series Rotogravure Printing Machine

ASYQD-E Series Rotogravure Printing Machine

-

FHQB Series High-Speed Slitter Rewinder

FHQB Series High-Speed Slitter Rewinder

-

ATS Cabinet

ATS Cabinet

-

Dalian Deutz Diesel Generator Sets

Dalian Deutz Diesel Generator Sets

-

QDTJ-400B Series Hot Stamping Machine

QDTJ-400B Series Hot Stamping Machine

-

FHQZ Series High-Speed Slitting and Rewinding Machine

FHQZ Series High-Speed Slitting and Rewinding Machine

-

Yuchai Marine Generator Sets

Yuchai Marine Generator Sets

-

Yuchai Engines

Yuchai Engines

-

QDF Series High-Speed Dry Laminating Machine

QDF Series High-Speed Dry Laminating Machine

-

SDEC Diesel Generator Sets

SDEC Diesel Generator Sets