E71T-1C Gas Shielded Mild Steel Flux Cored Wire

The E71T-1C gas shielded mild steel flux cored wire is the superior titanium slag offering stable welding, smooth arc, low spatter, high slag detachability and flawless bead. This CO2 flux cored wire is also endowed with outstanding mechanical property with low diffusible hydrogen level ≤5ml/100g.

Our flux cored wire (FCW) is well-suited for welding mild steel and low alloy with 500MPa tensile strength. This welding consumable is typically used in shipbuilding, bridge, general fabrication, storage vessel and boiler, as well as all structural steel erection.

Conformances

CCS (China Classification Society) in China

DNV (Det Norske Veritas) in Norway

LR (Lloyd's Register) in UK

ABS (The American Bureau of Shipping) in USA

GL (Germanischer Lloyd) in Germany

BV (Bureau Veritas) in French

NK (Nippon Kaiji Kyokai) in Japan

RINA (Registro Italiano Navale) in Italy

KR (Korean Register of Shipping) in Korean

RS (Russian Maritime Register of Shipping) in Russia

Standards

GB/T10045-2001 E501T-1

AWS A5.20 E71T-1C

Chemical composition of deposited metal (%)

| YC-YJ502 (Q) | C | Mn | Si | P | S |

| Standard | ≤0.18 | ≤1.75 | ≤0.90 | ≤0.03 | ≤0.03 |

| Typical | 0.07 | 1.25 | 0.36 | 0.016 | 0.012 |

Mechanical properties of deposited metal

| YC-YJ502 (Q) | Rm (MPa) | Rp (MPa) | A5 (%) | Akv (J) (-20℃) |

| Standard | 490-660 | ≥400 | ≥22 | ≥27 |

| Typical | 570 | 490 | 28 | 100 |

Recommended welding data (DC , shielding gas: CO2)

| Wire diameter (mm) | Current (A) | Voltage (V) | Gas (l/min) |

| Φ1.2 | 140-300 | 20-30 | 15-25 |

| Φ1.4 | 200-320 | 24-32 | 15-25 |

| Φ1.6 | 240-360 | 26-34 | 15-25 |

Links:https://globefindpro.com/products/76230.html

-

ER70S-G High Strength Welding Wire

ER70S-G High Strength Welding Wire

-

Electric Fence Poly Tape

Electric Fence Poly Tape

-

Polypropylene Fiber

Polypropylene Fiber

-

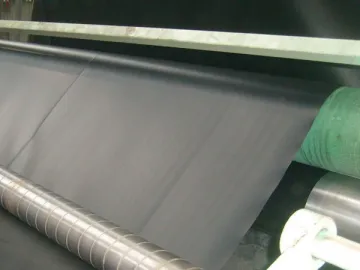

Geomembrane

Geomembrane

-

Electric Fence Poly Wire

Electric Fence Poly Wire

-

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

-

E70T-4 Self Shielded Mild Steel Flux Cored Wire

E70T-4 Self Shielded Mild Steel Flux Cored Wire

-

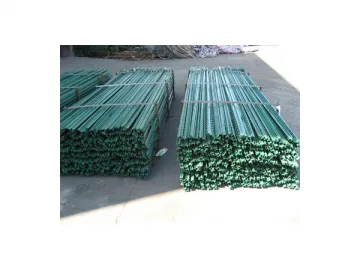

Steel Fence Post

Steel Fence Post

-

Electric Fence Poly Rope

Electric Fence Poly Rope

-

E70C-6M Metal Flux Cored Wire

E70C-6M Metal Flux Cored Wire

-

E6013 Welding Electrode

E6013 Welding Electrode

-

Copper Foil Tape

Copper Foil Tape