ER70S-G High Strength Welding Wire

The ER70S-G high strength welding wire is a kind of copper coated welding wire for low alloy steel. This gas shielded welding wire enjoys the company of CO2 or Argon-rich gas. Thanks to addition of Ti element, more refined deposition metal is achieved with outstanding mechanical properties.

This high strength welding wire is the industry-proven solution to applications requiring large current and high efficiency. Our filler material is designed for high-strength low-alloy steel (e.g. X65, 16Mn and 18Nb) applied to boiler, pressure vessel, bridge, hoisting machine, transport machine, engineering machinery, shipbuilding, pipeline and container, etc.

Standards

AWS A5.18 ER70S-G

GB/T:ER50-G

JIS:YGW11

Available diameter

0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm

Shielding gas

100% CO2 or 75%-95% Ar CO2

| C | Mn | Si | P | S | Ti | Cu | |

| Typical | 0.09 | 1.59 | 0.82 | 0.015 | 0.012 | 0.16 | 0.17 |

| Standard | ≤0.15 | 1.40-1.80 | 0.65-1.15 | ≤0.025 | ≤0.025 | ≥0.10 | ≤0.50 |

Note: Cu content in welding wire is the total amount of Cu contained in coating and self-contained Cu.

Mechanical properties of deposited metal| Rm (MPa) | Rp0.2 (MPa) | A (%) | Akv (J) (-30℃) | Shielding gas | |

| Typical | 587 | 432 | 29 | 62 | CO2 (Purity≥99.5%) |

| 613 | 502 | 28 | 72 | Argon-rich gas | |

| Standard | ≥580 | ≥420 | ≥22 | ≥27 |

Recommended welding data (DC )

| Wire diameter (mm) | 0.8 | 0.9 | 1.0 | 1.2 | 1.6 |

| Current (A) | 50-180 | 50-200 | 80-250 | 100-350 | 250-500 |

| Voltage (V) | 18-24 | 18-26 | 18-32 | 18-34 | 28-35 |

Note

1. This high strength welding wire should be stocked in dry. Package opens only before welding to avoid corrosion.

2. Please clean up surface pollutions such as oil stains, rusts and water before welding.

Packaging

Plastic or steel spool with 5kg or 15kg net weight each, sealed in heat shrink film

72 cartons/pallet, 22 pallets/20' container

Weight per spool: 1kg, 5kg, 15kg, 18kg, 20kg

Spool size: D100mm, D200mm, D270mm, D300mm, K300mm

Links:https://globefindpro.com/products/76231.html

-

Electric Fence Poly Tape

Electric Fence Poly Tape

-

Polypropylene Fiber

Polypropylene Fiber

-

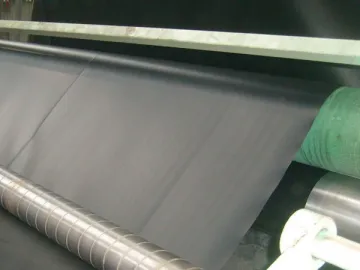

Geomembrane

Geomembrane

-

Electric Fence Poly Wire

Electric Fence Poly Wire

-

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

E70T-5C Gas Shielded Mild Steel Flux Cored Wire

-

Nylon Rope

Nylon Rope

-

E71T-1C Gas Shielded Mild Steel Flux Cored Wire

E71T-1C Gas Shielded Mild Steel Flux Cored Wire

-

E70T-4 Self Shielded Mild Steel Flux Cored Wire

E70T-4 Self Shielded Mild Steel Flux Cored Wire

-

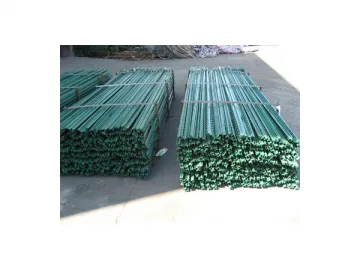

Steel Fence Post

Steel Fence Post

-

Electric Fence Poly Rope

Electric Fence Poly Rope

-

E70C-6M Metal Flux Cored Wire

E70C-6M Metal Flux Cored Wire

-

E6013 Welding Electrode

E6013 Welding Electrode