PE Film Blowing Machine

This blown-film extrusion process is used to produce both HDPE and LDPE shrink wraps. The main extruder uses variable frequency drive to enhance stability in speed regulation, which results in 30% electricity reduction. Made of 38CrMoAl, the extruder barrel has been through nitriding to gain a case hardened surface.

Belt carriers of the caterpillar haul-off are adjustable in height. Proper height adjustment allows effective cooling of hot plastic films of various sizes. Plenty of application exist for our PE film blowing machine, such as in the manufacture of laminating film, packing film, mulching film and other packaging films for textile and apparel.

Features

1. The PE film blowing machine uses 2 extruders that force two same or different PE resins into the same extrusion head (die). This process is generally known as co-extrusion. The resultant film has 2 layers with improved physical strength, air tightness and ability to keep out impurities.

2. The rotary extrusion die ensures quality plastic films with good flatness and uniform thickness. Shrink wraps coming out of this extrusion die can meet the quality requirements for further packaging and printing process. A variety of other plastic films can be produced using our rotary extrusion head, such as the pearlised film, laminating film for packaging liquid, insulation film, and multi-purpose mulching film.

3. Optimized screen changer design allows fast change of filtering screen.

4. Other desirable features include the length measurement device, slitter, cooling water drainage system, nip rolls, and trim scraps winding device.

Options

Automatic suction feeding system, embossing roller, surface treatment device, rotary extrusion die, air compressor, screen changer

Technical Specifications

| Model No. | YD-C50 | YD-C55 | YD-C65 | YD-C65-1 |

| Screw Diameter | Φ50mm | Φ55mm | Φ65mm | Φ65mm |

| Maximum Layflat Width | 100-550mm | 200-800mm | 300-1000mm | 400-1200mm |

| Thickness of Single Layer | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| Maximum Extrusion Output | 45Kg/h | 60Kg/h | 70Kg/h | 80Kg/h |

| L/D | 26:1 | 26:1 | 26:1 | 26:1 |

| Extruder Power | 7.5Kw | 11Kw | 15Kw | 18.5Kw |

| Caterpillar Haul-Off Power | 0.75Kw | 0.75Kw | 0.75Kw | 0.75Kw |

| Heating Power | 11Kw | 13Kw | 19Kw | 21Kw |

| Dimensions | 4800×1900×3450mm | 5500×2100×3800mm | 6500×2300×3800mm | 6500×2500×4600mm |

| Total Weight of the Film Blowing Machine | 1.5T | 2T | 2.3T | 2.6T |

Links:https://globefindpro.com/products/76819.html

-

Steel Wire Reinforced PVC Hose Extrusion Line

Steel Wire Reinforced PVC Hose Extrusion Line

-

PVC Wide Door Plate/Window Sill Board Extrusion Line

PVC Wide Door Plate/Window Sill Board Extrusion Line

-

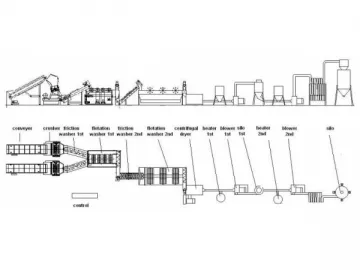

PP/PE Film Crushing Washing Recycling Line

PP/PE Film Crushing Washing Recycling Line

-

PVC Free Foam Sheet Extrusion Line

PVC Free Foam Sheet Extrusion Line

-

Single Screw Extruder

Single Screw Extruder

-

PVC/PE WPC(Foam) Profile Extrusion Line

PVC/PE WPC(Foam) Profile Extrusion Line

-

Conical Twin Screw Extruder

Conical Twin Screw Extruder

-

PP/PE/PC Hollow Grid Sheet Extrusion line

PP/PE/PC Hollow Grid Sheet Extrusion line

-

PP/PE Strand Granulating Line

PP/PE Strand Granulating Line

-

PP/PE/PS/ABS/PVC Single Layer/Multi-layer Sheet Extrusion Line

PP/PE/PS/ABS/PVC Single Layer/Multi-layer Sheet Extrusion Line

-

PP/PE Double Step Granulating Line

PP/PE Double Step Granulating Line

-

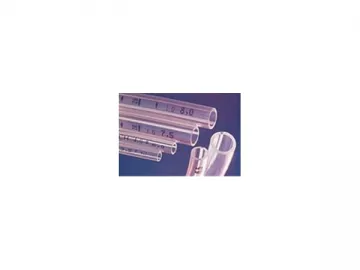

PP/PE/PU/PVC Medical Hose Extrusion Line

PP/PE/PU/PVC Medical Hose Extrusion Line