PVC Wide Door Plate/Window Sill Board Extrusion Line

The MS series profile extrusion line is mainly used to make PVC twinwall panels. Twinwall panels are good choices for partition walls, interior doors, and window sill boards. Operators can use PVC only to produce twinwall boards, but wood fibers also can be added to PVC to form rigid foam boards.

By replacing the forming die, users are able to employ this profile extrusion line for making various complex window and door profiles. High level of automation, stable performance, large extrusion output, high extrusion efficiency, optimized structure, and easy operation are several benefits of our equipment for its end users.

The resultant wood-plastic composite brings together the desirable features of wood and plastic. It simply looks better than natural wood but has similar machinability to the latter. A WPC board is easily sawed, nailed, and planed off. It is waterproof, antistatic, flame retardant, resistant to aging, bacteria, and strong acid and alkali, and unlikely to be attacked by insects. The WPC board is needed in large amounts around the world, as it is widely used as window and door profiles, conduits, and decorative materials.

Features

1. The extruder adopts the optimally design screw to create micro pores in the polymer resin, and enable uniform plasticization, and ensure high extrusion output.

2. Imported variable frequency drive offers consistent rotational speed and makes sure the extruder is synchronized in movement with other downstream components.

3. The vacuum sizing bench comes with a vortex cooling system for effective cooling of the hot extrudate. According to the specific extrusion die used, we would select a right sizing bench, including 4m, 6m, 8m and 10m, to accommodate high speed extrusion requirements.

4. Made with advanced elevation technology, the haul-off machine works stably with large traction force.

5. The cutter is synchronized in movement with the haul-off machine. It automatically measures the length to be cut.

6. A dust collector is added to our PVC profile extrusion line for clean operating environment.

Technical Specifications

| PVC Wide Door Panel/Window Sill Board/Siding Extrusion line | ||||

| Model No. | MS600 | MS800 | MS1000 | MS1250 |

| Finished Product Width (mm) | 600 | 800 | 1000 | 1250 |

| Extruder Model No. | SJSZ80/156 | SJSZ80/156 | SJSZ92/188 | SJSZ92/188 |

| Main Motor Power (kw) | 55 | 55 | 132 | 132 |

| Maximum Output (kg/h) | 450 | 450 | 600 | 600 |

| Water Consumption (m³/h) | 10 | 12 | 15 | 18 |

| Air Consumption (m³/h) | 0.6 | 0.8 | 1 | 1.2 |

| Dimensions (mm) | 28000×1800×2700mm | 32000×1950×2800mm | ||

| Weight (kg) | 17000kg | 22000kg | ||

Links:https://globefindpro.com/products/76822.html

-

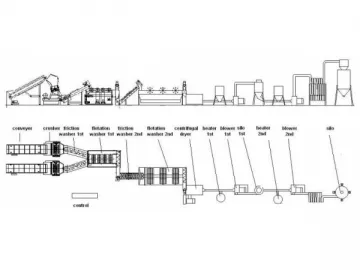

PP/PE Film Crushing Washing Recycling Line

PP/PE Film Crushing Washing Recycling Line

-

PVC Free Foam Sheet Extrusion Line

PVC Free Foam Sheet Extrusion Line

-

Single Screw Extruder

Single Screw Extruder

-

PVC/PE WPC(Foam) Profile Extrusion Line

PVC/PE WPC(Foam) Profile Extrusion Line

-

PVC Window and Door Profile Extrusion Line

PVC Window and Door Profile Extrusion Line

-

PET Bottle Flakes Crushing Washing Drying Recycling Line

PET Bottle Flakes Crushing Washing Drying Recycling Line

-

Steel Wire Reinforced PVC Hose Extrusion Line

Steel Wire Reinforced PVC Hose Extrusion Line

-

PE Film Blowing Machine

PE Film Blowing Machine

-

Conical Twin Screw Extruder

Conical Twin Screw Extruder

-

PP/PE/PC Hollow Grid Sheet Extrusion line

PP/PE/PC Hollow Grid Sheet Extrusion line

-

PP/PE Strand Granulating Line

PP/PE Strand Granulating Line

-

PP/PE/PS/ABS/PVC Single Layer/Multi-layer Sheet Extrusion Line

PP/PE/PS/ABS/PVC Single Layer/Multi-layer Sheet Extrusion Line