PVC/PE WPC(Foam) Profile Extrusion Line

This profile extrusion line combines new or recycled plastics with wood fibers to produce an industrial product known as the wood plastic composites. The plastics including PVC, PE, and PP, along with the wood flours and other plant fiber like rice chaff and crop straw, accounts for more than 90% of the total contents in the wood plastic composite.

The resultant foam board can be used for building models, toy blocks, pallets, packing case, and shipping container, etc. Other uses are listed as follows.

1. Floorboard, wooden sleeper

2. Outdoor floor, deck railing, garden bench

3. Sunroom, signage, transfer container, stadium chair, load-bearing beam

Benefits involved in the use of PVC/PE WPC foam boards include:

1. An ideal substitute for wood, which saves forest reserves

2. The foam board is made of wasted crop stems, which helps protect environment.

3. Using recycled plastics as raw materials reduces white pollution.

Technical Specifications

| Profile Extrusion Line Model No. | SJZ65/132 | SJZ80/156 | SJZ92/188 |

| Power | 37KW | 55KW | 110KW |

| Production Capacity | 250 Kg/h | 360 Kg/h | 600 Kg/h |

| Center of Gravity Height | 1000mm | 1000mm | 1050mm |

| Dimensions | 24000×1800×2700 | 28000×1800×2700mm | 32000×1950×2800mm |

| Weight | 12000kg | 17000kg | 22000kg |

Links:https://globefindpro.com/products/76826.html

-

PVC Window and Door Profile Extrusion Line

PVC Window and Door Profile Extrusion Line

-

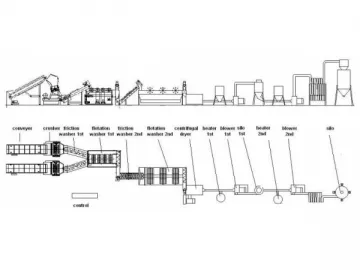

PET Bottle Flakes Crushing Washing Drying Recycling Line

PET Bottle Flakes Crushing Washing Drying Recycling Line

-

102 Series Induction High Bay Light

102 Series Induction High Bay Light

-

Metal Halide Lamp (G8.5/G12/R7S/FC2)

Metal Halide Lamp (G8.5/G12/R7S/FC2)

-

Apollo Series LED Grow Light

Apollo Series LED Grow Light

-

Illusion Series LED Grow Light

Illusion Series LED Grow Light

-

Single Screw Extruder

Single Screw Extruder

-

PVC Free Foam Sheet Extrusion Line

PVC Free Foam Sheet Extrusion Line

-

PP/PE Film Crushing Washing Recycling Line

PP/PE Film Crushing Washing Recycling Line

-

PVC Wide Door Plate/Window Sill Board Extrusion Line

PVC Wide Door Plate/Window Sill Board Extrusion Line

-

Steel Wire Reinforced PVC Hose Extrusion Line

Steel Wire Reinforced PVC Hose Extrusion Line

-

PE Film Blowing Machine

PE Film Blowing Machine