Hydraulic Press Brake

Our WC67Y series hydraulic press brake features with scientific structure, reliable performance, and easy operation. It is widely used for the processing of iron tower, street lighting pole, high mast pole, automotive frame, automobile container, and so on.

Feature

1. The structure of the bending machine is welded by steel plate, so the welding residual stress can be effectively reduced during the vibration. Thus the rigidity and the stability of the machine are excellent.

2. The oil cylinders in parallel connection are adopted in the hydraulic press brake. To ensure the precise positioning of the sliding block, a mechanical stopper is available in the oil cylinder and controlled by a motor. A mechanical synchronizing mechanism is used for the synchronization of the sliding block.

3. The hydraulic manifold block is used to minimize the usage of connecting pipe, thus the reliability will be enhanced and the maintenance will be simplified.

4. In this hydraulic metal processing machine, a motor driven screw is used to move the rear baffle back and forth horizontally. The size of the baffle is indicated by a digital display for convenient usage.

5. The molds of the hydraulic press brake are made of alloy steel, and processed by forging, milling, and polishing techniques. The moving die is made up with several short dies. Thus the moving die is highly precise, and can be interchanged as you wish, while it is also convenient to assemble and remove it.

Technical parameter

| Specification | Rated pressure (KN) | Working table length (mm) | Post interval (mm) | Throat depth (mm) | Sliding block stroke (mm) | Main motor power (kw) |

| WC67Y-63/2500 | 630 | 2500 | 1900 | 250 | 120 | 5.5 |

| WC67Y-63/3200 | 630 | 3200 | 2500 | 250 | 120 | 5.5 |

| WC67Y-80/3200 | 800 | 3200 | 2500 | 250 | 120 | 5.5 |

| WC67Y-80/4000 | 800 | 4000 | 3000 | 250 | 120 | 5.5 |

| WC67Y-100/2500 | 1000 | 2500 | 1900 | 320 | 120 | 7.5 |

| WC67Y-100/3200 | 1000 | 3200 | 2500 | 320 | 120 | 7.5 |

| WC67Y-100/4000 | 1000 | 4000 | 3000 | 320 | 120 | 7.5 |

| WC67Y-100/5000 | 1000 | 5000 | 4000 | 320 | 120 | 7.5 |

| WC67Y-125/2500 | 1250 | 2500 | 1900 | 320 | 120 | 7.5 |

| WC67Y-125/3200 | 1250 | 3200 | 2500 | 320 | 120 | 7.5 |

| WC67Y-125/4000 | 1250 | 4000 | 3000 | 320 | 120 | 7.5 |

| WC67Y-125/5000 | 1250 | 5000 | 4000 | 320 | 120 | 7.5 |

| WC67Y-160/3200 | 1600 | 3200 | 2500 | 320 | 200 | 11 |

| WC67Y-160/4000 | 1600 | 4000 | 3000 | 320 | 200 | 11 |

| WC67Y-160/5000 | 1600 | 5000 | 4000 | 320 | 200 | 15 |

| WC67Y-160/6000 | 1600 | 6000 | 4800 | 320 | 200 | 15 |

| WC67Y-200/3200 | 2000 | 3200 | 2600 | 250 | 200 | 18.5 |

| WC67Y-200/4000 | 2000 | 4000 | 3100 | 320 | 200 | 18.5 |

| WC67Y-200/5000 | 2000 | 5000 | 4000 | 320 | 200 | 18.5 |

| WC67Y-200/6000 | 2000 | 6000 | 4800 | 320 | 200 | 18.5 |

| WC67Y-250/3200 | 2500 | 3200 | 2600 | 400 | 250 | 22 |

| WC67Y-250/4000 | 2500 | 4000 | 3200 | 400 | 250 | 22 |

| WC67Y-250/5000 | 2500 | 5000 | 4000 | 400 | 250 | 22 |

| WC67Y-300/4000 | 3000 | 4000 | 3300 | 400 | 250 | 22 |

| WC67Y-300/5000 | 3000 | 5000 | 4000 | 400 | 250 | 22 |

| WC67Y-300/6000 | 3000 | 6000 | 5800 | 400 | 250 | 22 |

| WC67Y-400/5000 | 4000 | 5000 | 4000 | 400 | 250 | 30 |

| WC67Y-400/6000 | 4000 | 6000 | 4800 | 400 | 250 | 37 |

| WC67Y-500/6000 | 5000 | 6000 | 4800 | 400 | 300 | 37 |

| WC67Y-600/7000 | 6000 | 7000 | 5100 | 400 | 300 | 45 |

| WC67Y-700/7000 | 7000 | 7000 | 5100 | 400 | 300 | 45 |

| WC67Y-800/6000 | 8000 | 6000 | 4800 | 500 | 400 | 55 |

Links:https://globefindpro.com/products/77084.html

-

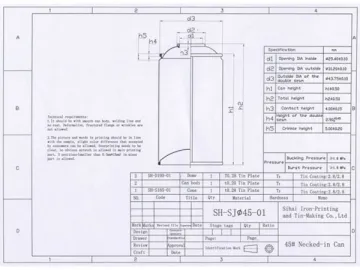

45mm Diameter Aerosol Can

45mm Diameter Aerosol Can

-

Four Column Hydraulic Press

Four Column Hydraulic Press

-

Uncoiling, Leveling and Cutting Line (Thin Plate)

Uncoiling, Leveling and Cutting Line (Thin Plate)

-

Artificial Podocarpus

Artificial Podocarpus

-

Artificial Monstera Deliciosa

Artificial Monstera Deliciosa

-

Artificial Green Wall

Artificial Green Wall

-

J23 Series C Frame Inclinable Press

J23 Series C Frame Inclinable Press

-

Z Channel Rolling Machine

Z Channel Rolling Machine

-

Plate Bending Roll for Shipbuilding Industry

Plate Bending Roll for Shipbuilding Industry

-

Artificial Cypress

Artificial Cypress

-

Artificial Stellaria Alsine

Artificial Stellaria Alsine

-

Artificial Butterfly Orchid

Artificial Butterfly Orchid