Four Column Hydraulic Press

The YHD series four column hydraulic press we provide adopts a three-beam and four-column structure for its gantry parts. After the welding, each gantry will be subjected to tempering and aging treatment, so that the stress in the welded gantry can be lowered to an extremely low degree. The column has been tempered as a whole, while its surface, after treated by high frequency quenching technique, will be treated by cylindrical grinding technique or chrome plating technique. Thus the columns could get really excellent in terms of precision and anti-wear performance.

Our four column hydraulic press, as a powerful hydraulic press forming machine, is suitable for pressing (such as blanking, bending, curring, thin plate stretching) malleable materials, as well as calibrating, press fitting, grinding wheel forming, metal component extrusion forming, and the pressing forming of plastic and powder products. Specifically, it is very suitable for some situations in which a once forming operation is needed for several components, however, the loading space is too small for manual loading, such as in the lighter, watch, and toy industries.

Feature

1. As a professional hydraulic press manufacturer, this four column hydraulic press is outfitted with independent driving mechanism and electronic system, and controlled by a relay. Thus it can work under the manual adjusting mode and semi-automatic operation mode.

2. As a hydraulic press with four columns, its working pressure and sliding block stroke range are adjustable according to the techniques you required. It can work with either certain pressure or certain stroke distance. Especially, after the press forming with certain pressure, there are two more steps followed-pressure keeping and delayed automated return stroke.

Technical parameter

| Model | YHD32-100 | YHD32-400 | YHD32-500 | YHD32-630 | YHD32-315 | YHD32-40T | YHD32-63T | YHD32-160 | |

| Rated pressure | 1000KN | 4000KN | 5000KN | 6300KN | 3150KN | 400KN | 630KN | 1600KN | |

| Ejection pressure | 1900KN | 630 KN | 1000KN | 1000KN | 630 KN | 120KN | 190 KN | 400KN | |

| Max. hydraulic pressure | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | |

| Max. opening height | 880mm | 1250mm | 1500mm | 1500mm | 1250mm | 700mm | 750mm | 1000mm | |

| Sliding stroke | 600mm | 800mm | 900mm | 900mm | 800mm | 450mm | 500mm | 700mm | |

| Ejection stroke | 200mm | 300mm | 350mm | 300mm | 150mm | 200mm | 200mm | ||

| Table effective size | Left-Right | 720mm | 1240mm | 1400mm | 1500mm | 1260mm | 1200mm | 580mm | 780mm |

| Front-Back | 580mm | 1200mm | 1400mm | 1500mm | 1200mm | 1000mm | 500mm | 640mm | |

| Speed of sliding block | Empty descending | 120mm/s | 100mm/s | 100mm/s | 80mm/s | 100mm/s | 20mm/s | 20mm/s | 2700mm |

| Pressing | 14mm/s | 5-7mm/s | 5mm/s | 10mm/s | 6-8mm/s | 14mm/s | 14mm/s | 1700mm | |

| Return | 120mm/s | 45mm/s | 70mm/s | 60mm/s | 60mm/s | 45mm/s | 120mm/s | 3400mm | |

| Motor Power | 7.5KW | 15KW | 37KW | 44KW | 18.5KW | 5.5KW | 7.5KW | 11KW | |

Links:https://globefindpro.com/products/77087.html

-

Uncoiling, Leveling and Cutting Line (Thin Plate)

Uncoiling, Leveling and Cutting Line (Thin Plate)

-

Artificial Podocarpus

Artificial Podocarpus

-

Artificial Monstera Deliciosa

Artificial Monstera Deliciosa

-

Artificial Green Wall

Artificial Green Wall

-

Artificial Date Palm Tree

Artificial Date Palm Tree

-

Artificial Pine Tree

Artificial Pine Tree

-

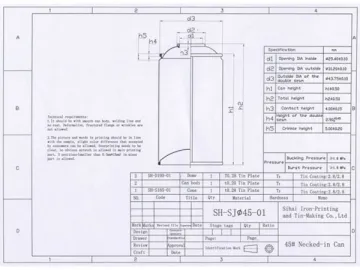

45mm Diameter Aerosol Can

45mm Diameter Aerosol Can

-

Hydraulic Press Brake

Hydraulic Press Brake

-

J23 Series C Frame Inclinable Press

J23 Series C Frame Inclinable Press

-

Z Channel Rolling Machine

Z Channel Rolling Machine

-

Plate Bending Roll for Shipbuilding Industry

Plate Bending Roll for Shipbuilding Industry

-

Artificial Cypress

Artificial Cypress